39034, 036, 036 QS

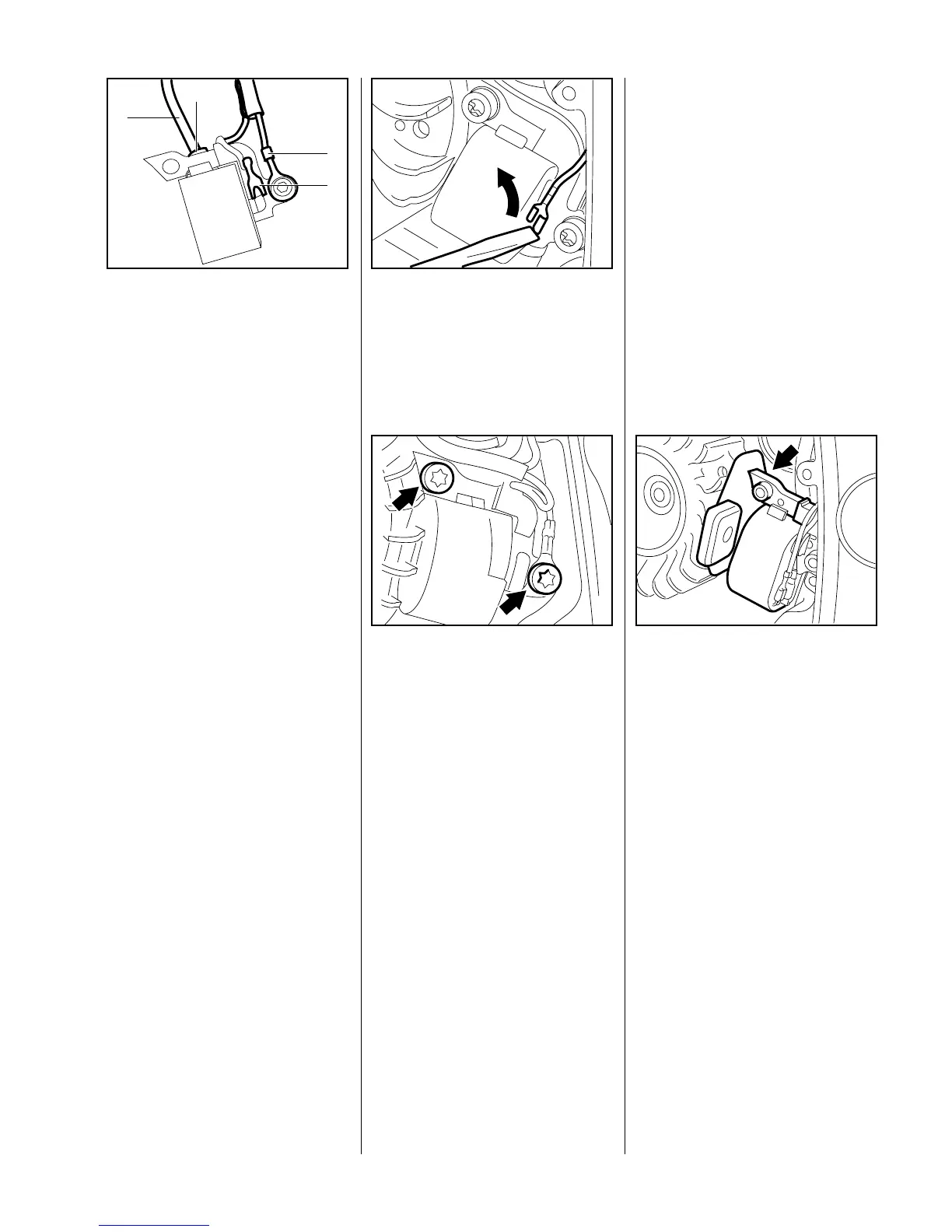

The ignition module accommodates

all the components required to

control ignition timing.

Ignition module components and

connections

1 Ignition lead with insulating tube

VA

138RA103

1

4

3

2

2 High voltage output

3 Ground wire

4 Connector tag for

short circuit wire

Accurate testing of the ignition

module is only possible with special

test equipment. For this reason it is

only necessary to carry out a spark

test in the workshop.

A new ignition module must be

installed if no ignition spark is

obtained (after checking that wiring

and stop switch are in good

condition).

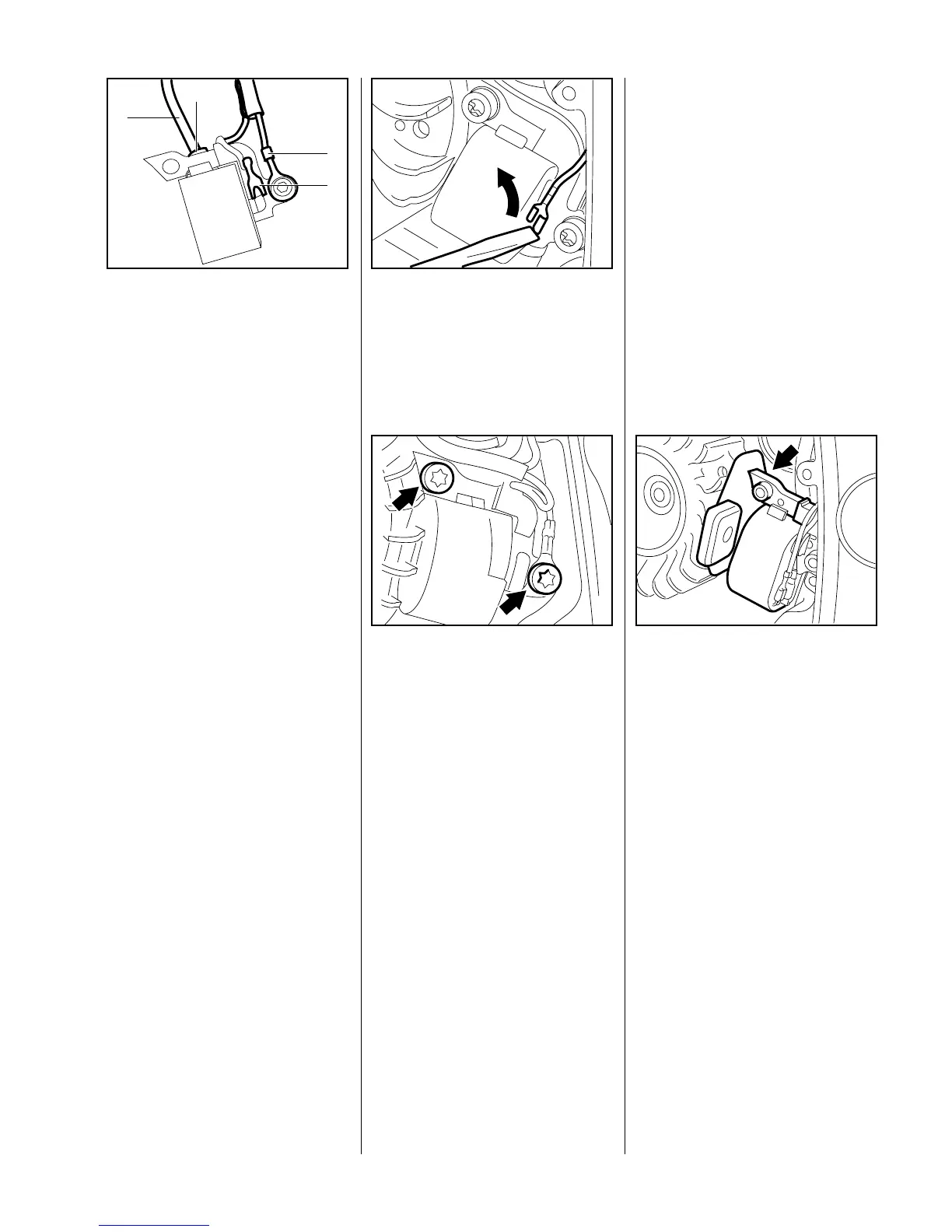

– Remove the fan housing - see

6.4.1

Use a screwdriver to disconnect

the short circuit wire from the

ignition module.

VA

138RA104

Take out the two mounting

screws and lift away the ignition

module.

Note:

If the ignition module is faulty,

unscrew the ignition lead

counterclockwise and transfer it

VA

138RA105

along with the spark plug boot and

cable retainer to the new ignition

module.

– To install the ignition module,

connect short circuit wire to tag

on ignition module and then push

the short circuit wire into the

retainer.

– Place the ignition module in the

crankcase.

– Coat threads of ignition module

mounting screws with LOCTITE -

see 13.2.

– Use lower mounting screw to

connect the ground wire to the

ignition module.

Fit the two screws and tighten

them down moderately.

– Rotate the flywheel until the

magnets are between the two

arms of the ignition module.

Slide the setting gauge

1111 890 6400 or 0.2 mm metal

gauge between the arms of the

ignition module and the flywheel

magnets.

– Press the ignition module against

the flywheel and tighten down the

VA

138RA107

mounting screws (see

"Tightening Torques").

Important:

Tighten the upper screw first.

– Remove the setting gauge and

use a feeler gauge to check the

air gap. It should be 0.2 to

0.3 mm.

– Fit the fan housing - observe

tightening torques (see

"Tightening Torques").

6.5 Ignition Module 6.5.1 Removing and Installing

Loading...

Loading...