Online version - not for reprint

33MS 270, MS 280

Always check and, if necessary,

repair the fuel system, carburetor,

air filter and ignition system before

looking for faults on the engine.

Troubleshooting chart – see 4.6.

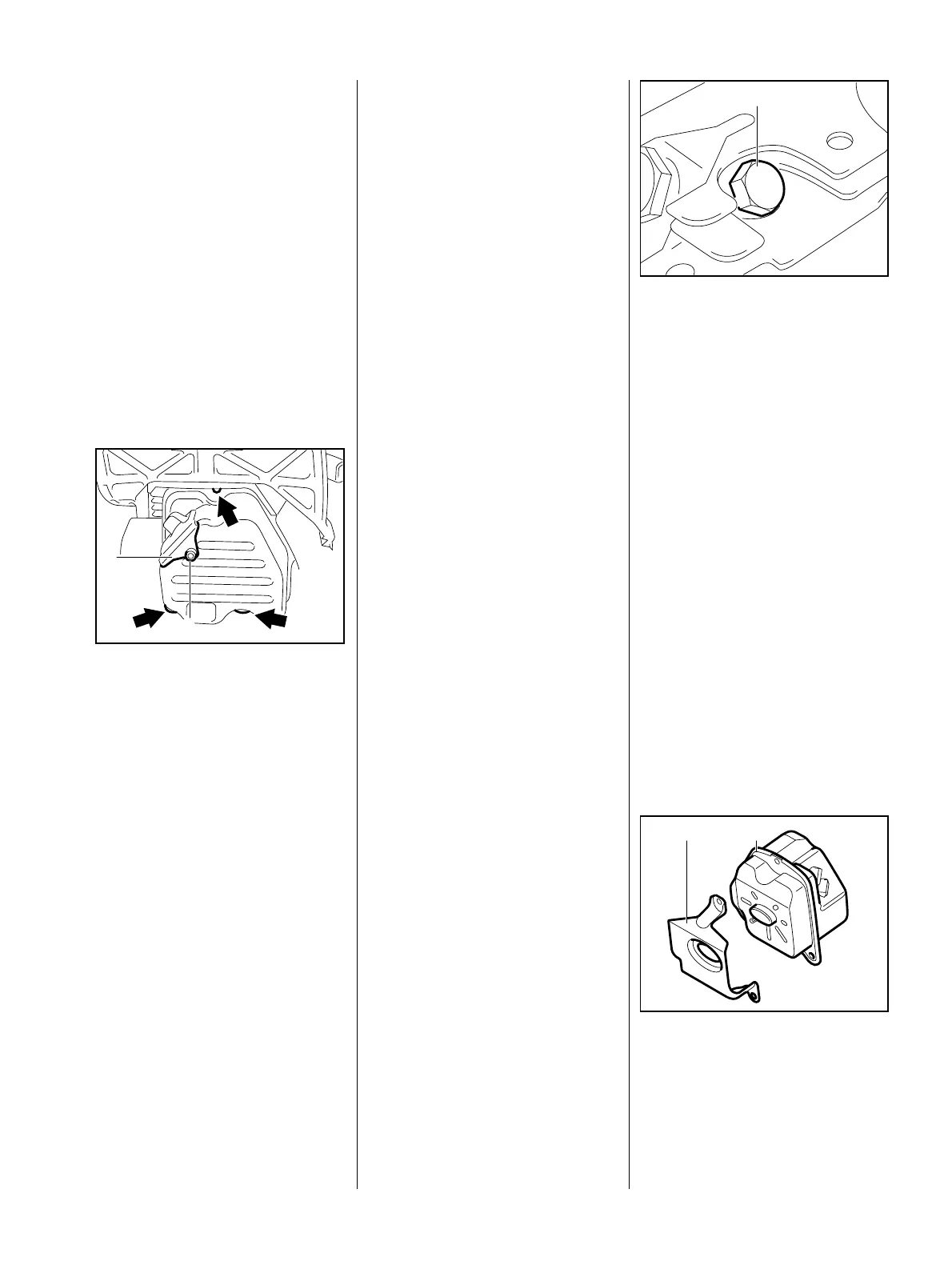

Take out the screws (arrows).

– Remove the muffler.

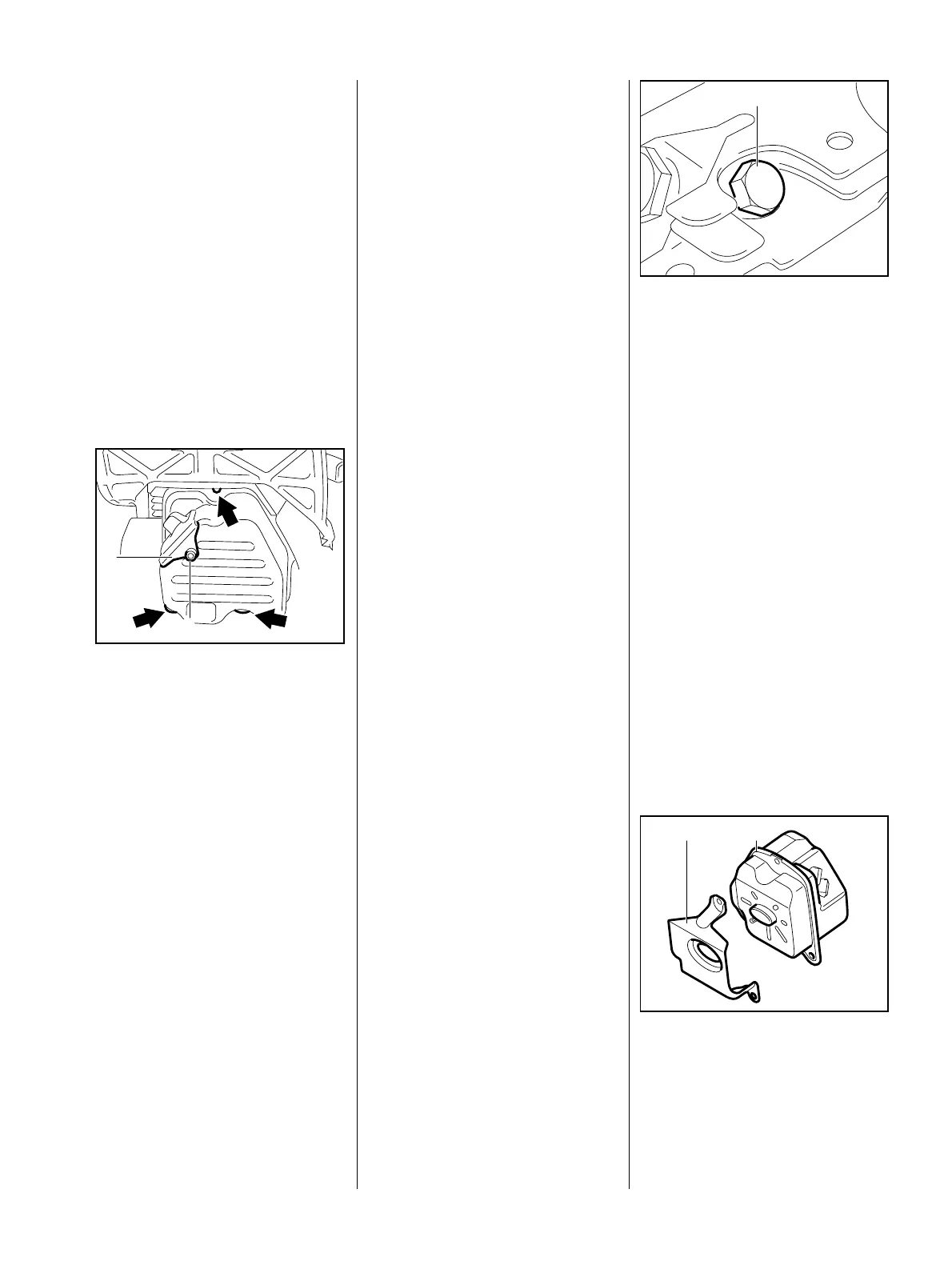

Take out the screw (1), if fitted,

and pull out the spark arresting

screen (2).

VA

146RA026

2

1

Inspect spark arresting

screen (2) for damage, clean or

replace if necessary.

Reassemble in the reverse

sequence.

Defective oil seals and gaskets or

cracks in castings are the usual

causes of leaks. Such faults allow

supplementary air to enter the

engine and upset the fuel-air

mixture.

This makes adjustment of the

prescribed idle speed difficult, if not

impossible.

Moreover, the transition from idle

speed to part or full throttle is not

smooth.

The crankcase can be checked

thoroughly for leaks with the

carburetor and crankcase tester

and the vacuum pump.

– Remove the shroud – see 6.4.

– Remove the decompression

valve, if fitted – see 6.8.

Install plug (1) 1122 025 2200

and tighten down to 25 Nm.

VA

146RA028

1

– Make sure spark plug is properly

tightened down – see 3.5.

– Remove the muffler – see 6.1.

Remove the heat shield (1) from

the muffler (2).

146RA214

21

VA

6 Engine

6.1 Muffler/Spark Arresting

Screen

6.2 Leakage Test 6.2.1 Preparations

Loading...

Loading...