Online version - not for reprint

30 MS 270, MS 280

Check operation of the brake with

the bar and chain mounted.

When starting the machine observe

country-specific safety regulations

and the safety precautions in the

owner’s manual.

– With the engine running, open

the throttle wide.

– Release the rear handle.

The chain must come to a standstill

in less than one second.

If the brake does not operate

properly, service the sliding and

bearing points shown in the

illustrations as follows:

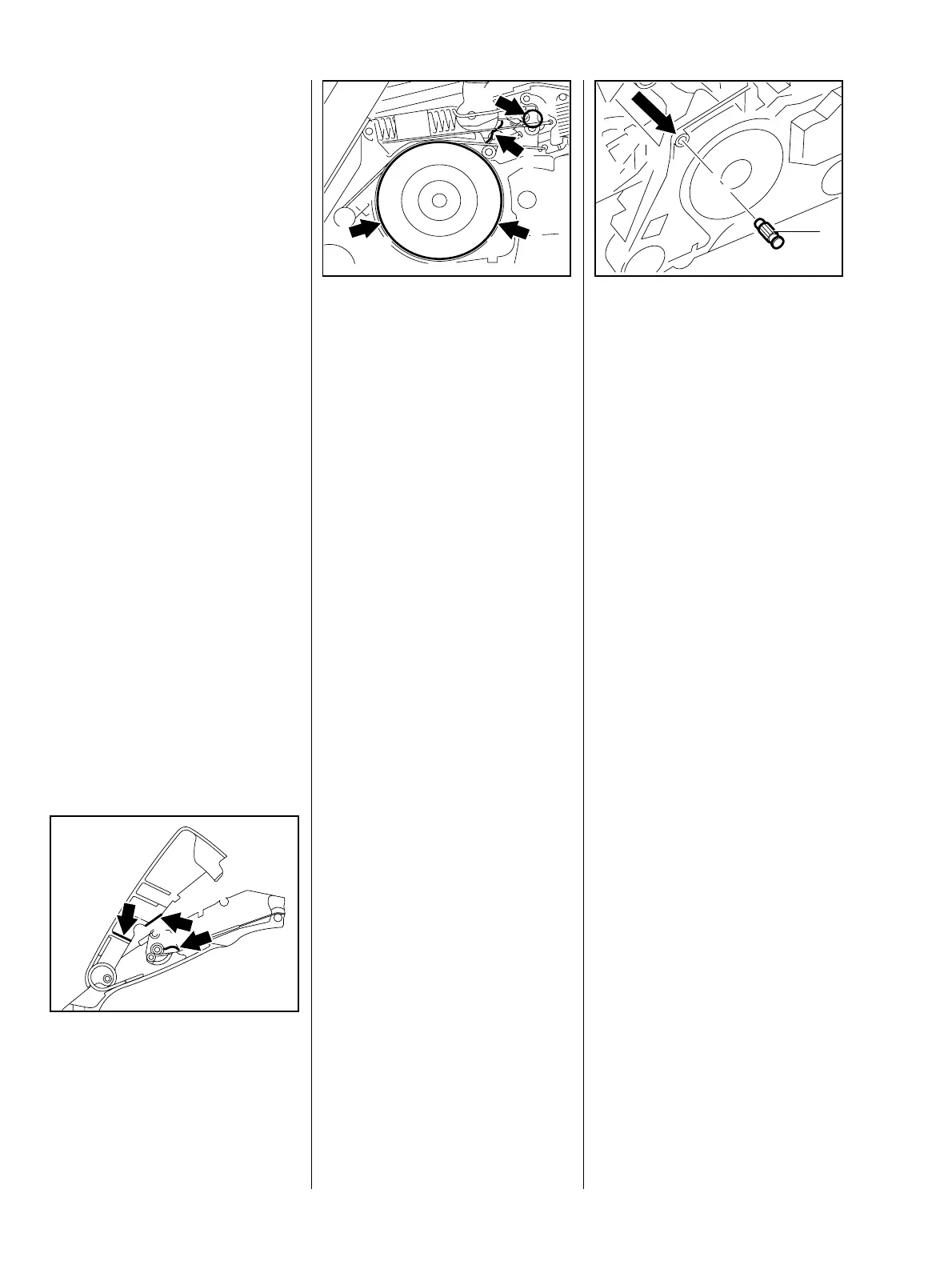

Lubricate bearing points (arrows)

of interlock and switch levers with

Mobilplex grease – see 14.

VA

148RA047

Lubricate brake lever bearing

points (1) with grease – see 14.

Coat outside diameter of clutch

drum (2) with chain oil – see 14.

If lightly contaminated:

VA

148RA048

1

1

2

2

– Clean all parts with a brush and

STIHL cleaner – see 14.

If heavily contaminated or

clogged with resin:

– Remove the parts concerned and

clean in STIHL cleaner – see 14.

– Replace worn or damaged parts.

– Before re-installing parts, clean

machine recesses and seats with

STIHL cleaner – see 14.

If a biological chain oil is preferred,

STIHL recommends the use of

rapidly biodegradable STIHL

Bioplus.

To guarantee troublefree operation,

use only original STIHL replace-

ment parts as per the latest parts

list.

Removing

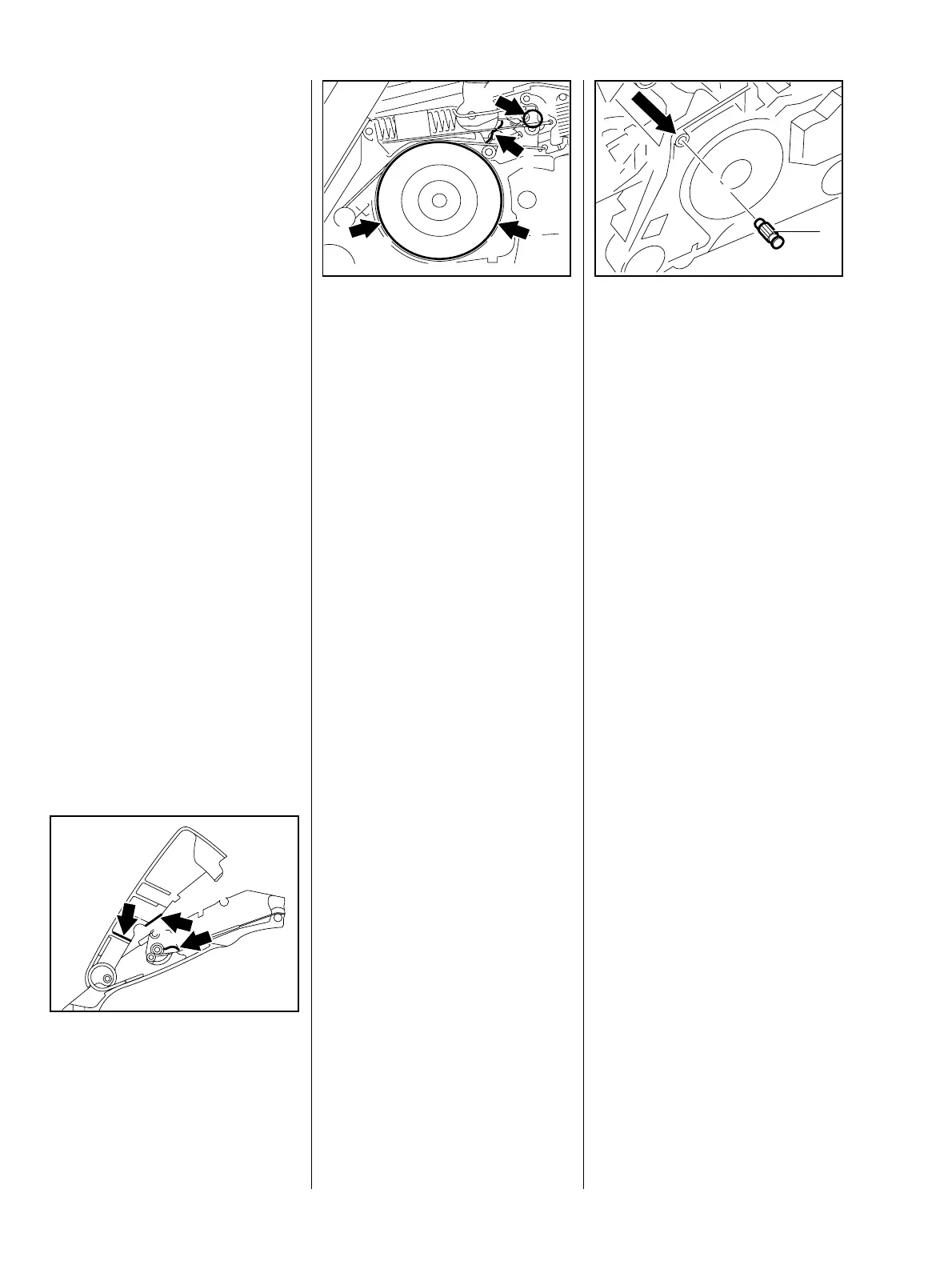

The anchor pin (1) must be replaced

if it is worn or damaged:

– Remove the fan cover

– see 8.2.

VA

146RA194

1

– Remove the chain brake spring

– see 5.4.2 or see 5.5.1.

– Remove the shroud – see 6.4.

Use a suitable punch to drive the

anchor pin (1) out of the

crankcase in the direction of the

arrow.

Do not drive out the pin in the other

direction as this would damage the

annular bead which was formed in

the crankcase bore when the pin

was originally installed. In such a

case neither the new anchor pin nor

the brake spring would locate

properly. Furthermore, the

crankcase could be damaged in this

way and possibly impair correct

operation of the chain brake.

5.5.6 Checking Operation of

Coasting Brake

5.6 Brake Spring Anchor Pin

Loading...

Loading...