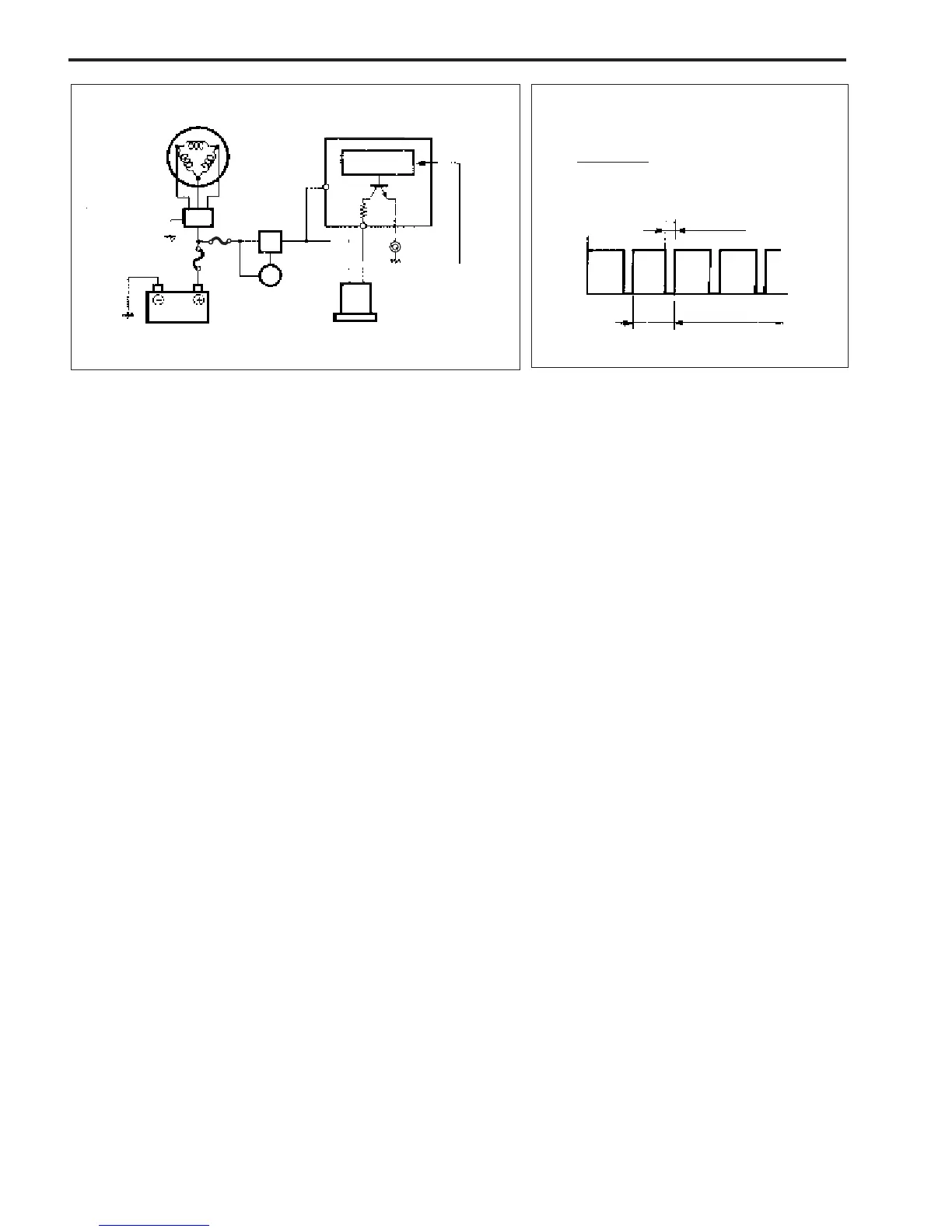

3-22 ENGINE CONTROL SYSTEM

ECM

CPU

Sensor / switch

signal input

IAC valve

Ignition

switch

Battery

60A fuse

Rectifier &

regulator

Battery

charge

coil

ECM

main

relay

30A fuse

CONTROL MODE

BEFORE START :

The IAC valve is closed (0% duty) when engine is not running (but ignition switch is ON).

WHEN CRANKING :

The IAC valve is controlled to operate at approx. 80% duty.

AFTER START (FAST-IDLE FUNCTION) :

The IAC valve is controlled to operate at approx. 25 – 50% duty until the timer, which was set according to

cylinder temperature at cranking, expires.

WHEN IDLING / TROLLING :

The IAC valve is controlled so that the engine speed is stable at the idling / trolling speed specified.

During this period, the IAC valve has a duty cycle of approx. 15% but will vary slightly as idling / trolling

conditions change.

WHEN RUNNING (NORMAL OPERATION) :

The IAC valve is controlled to operate at 20 – 50% duty, which depends on the current engine conditions.

WHEN DECELERATING (DASH-POT EFFECT) :

When the throttle valve is suddenly returned to full close and the CTP switch signal changes to “ON”, the IAC

valve operates at a controlled gradual return to idle / troll operating duty to prevent engine stalling or unstable

running.

NOTE:

Due to the limited intake air flow from the IAC passage and in order to effectively use both the “Dash-pot

effect” and “Fast-idle function”, the by-pass air screw must be adjusted to provide IAC valve operation at

approx. 15% duty at the engine idling / trolling specification.

See page 2-14 for the by-pass air screw adjustment procedure.

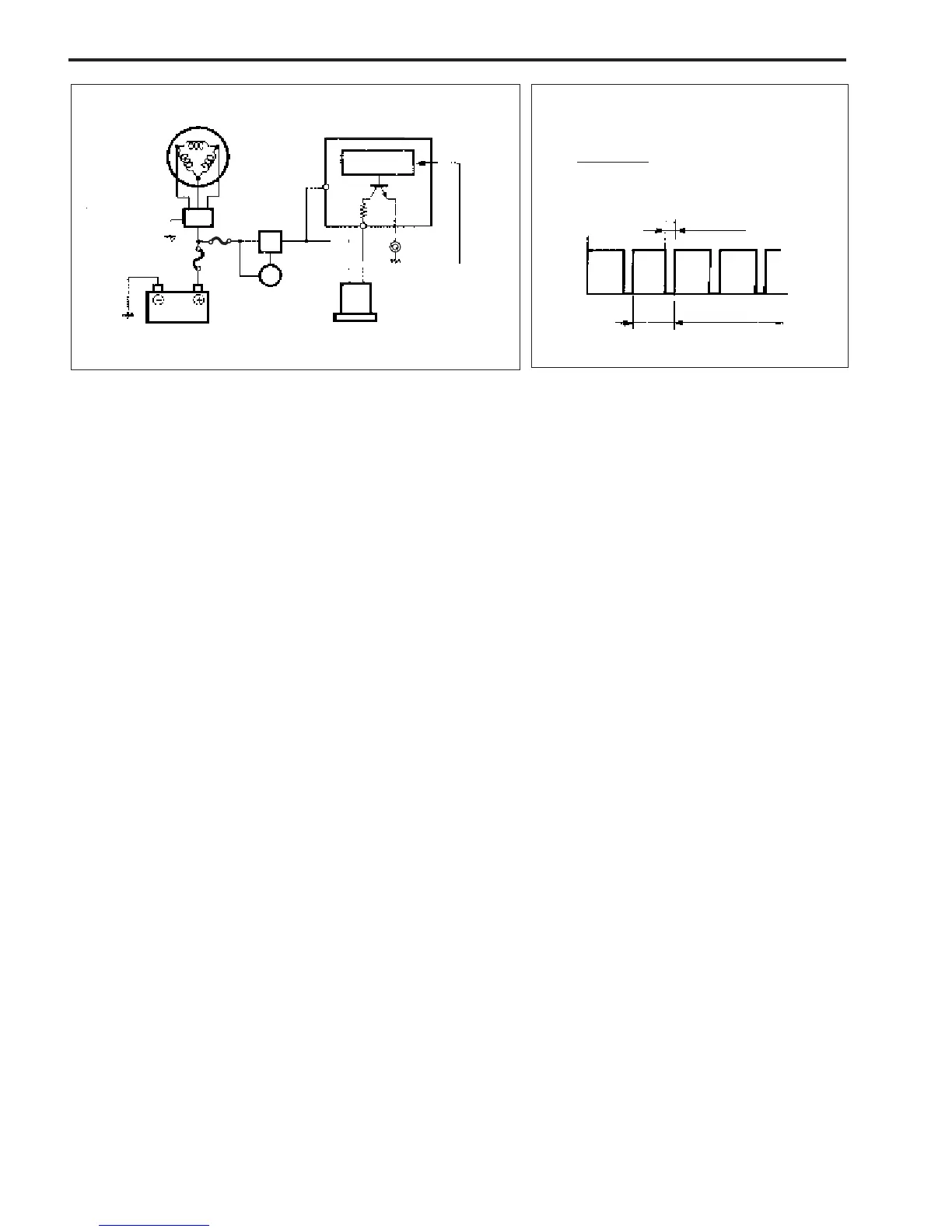

Duty cycle signal for IAC valve

(example : 20% duty)

“ON” time

1 cycle time

× 100 = duty (%)

0.8 ms

Time

4 ms (1cycle)

OFF

ON

Loading...

Loading...