102

6

7

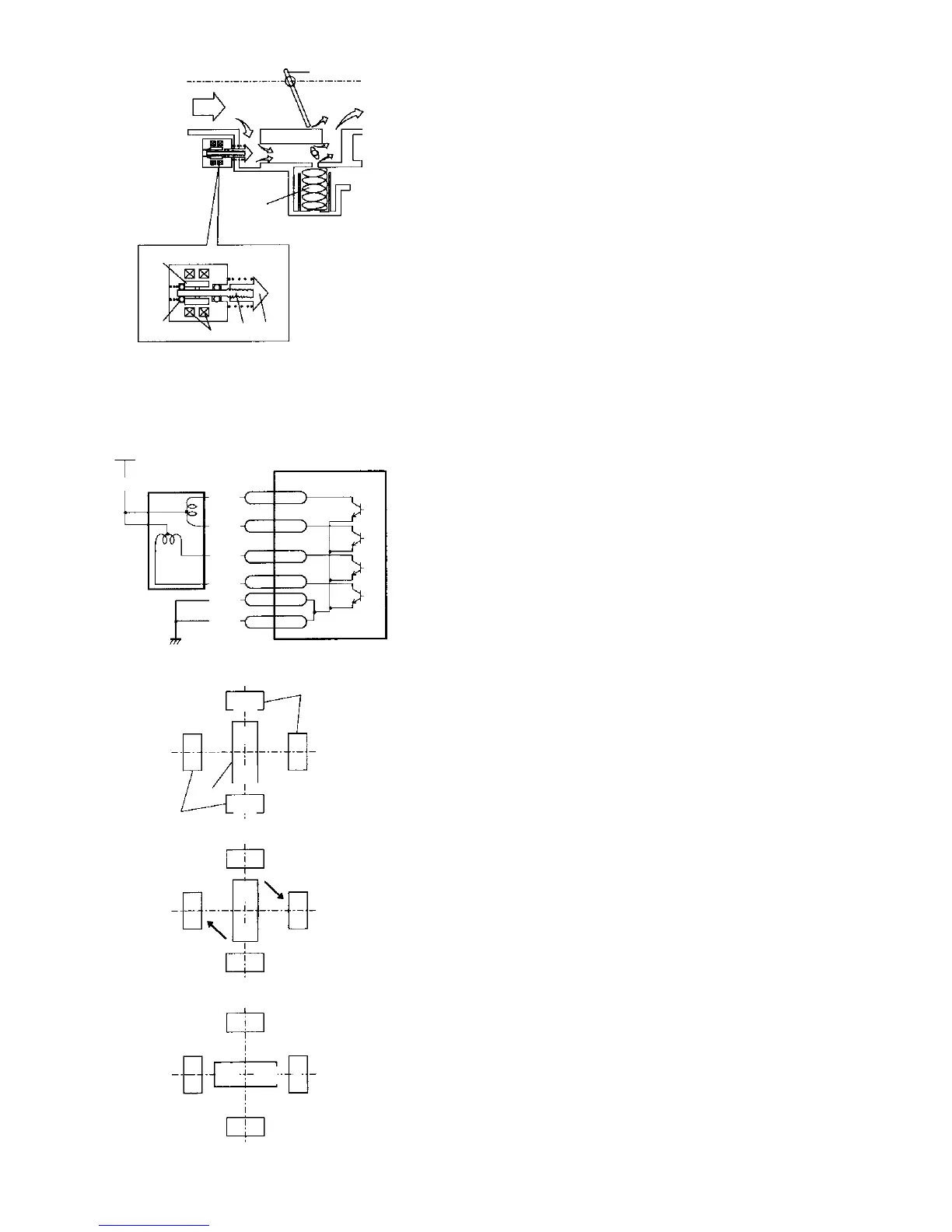

ICS VALVE

3

5

4

2

1

1. VALVE PINTLE

2. SCREW SHAFT

3. MAGNET (ROTOR)

4. COIL

5. BEARING

6. THROTTLE VALVE

7. BIMETAL TYPE

LIMITER VALVE

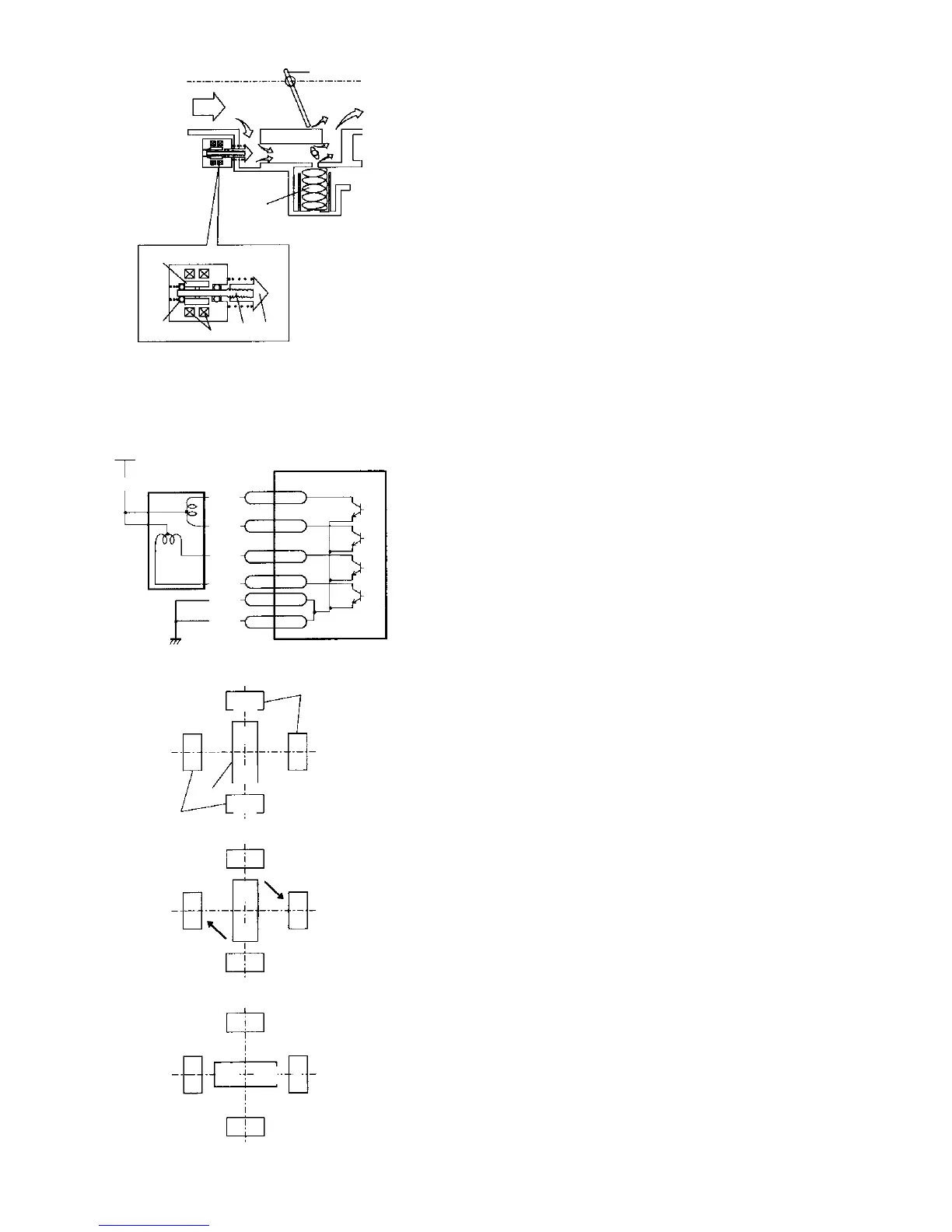

+12V

(VIA RELAY)

B/R

ISC VALVE

11

SMA

12 SMB

13

SMC

14

SMD

9 E01

E1

17

ECM

R/B

R

R/Y

R/BL

B/BL

B

COLOR CODE

B – BLACK

R – RED

Y – YELLOW

BL – BLUE

N

S

S

N

8

8

9

STATUS (1)

S

N

SN

SUCTION

FORCE

SUCTION

FORCE

STATUS (2) STATOR SWITCHING

SN

S

N

STATUS (3) ROTOR ROTATION

8. STATOR

9. ROTOR

ISC Valve

The ISC valve controls the bypass air amount and

stabilizes the idling rpm.

The ISC valve is installed on the throttle body and

uses a stepper motor system.

The transistor for driving the ISC valve in the ECM

receives an instruction from the CPU and switches

ON or OFF, the step motor in the ISC valve rotates a

number of steps proportional to the instruction, driv-

ing the valve, thereby the bypass passage is opened

or closed, and the engine is controlled to the target

idling rpm. The stepper motor rotates using the mag-

netic attraction of a stator and rotor. When the

excitation of the stator is switched from the state (1)

in the figure to the left, becoming state (2), torque in

the magnetic rotational direction is produced in the

rotor, and a stable position is achieved in state (3) by

the rotation of the rotor. (The figure to the left shows

the operating principle of the stator rotor and may be

different from that actually used. The actual system

uses two–phase excitation.) By repeating this, the

rotor turns in a number of steps according to the

instruction of the ECM, the rotation is converted to

torque (extension–contraction) via a screw shaft,

and the ISC flow amount is changed by the stroke of

the valve pintle.

A battery voltage is fed to the center terminal of the

two coils from the main relay when the ignition

switch is ON, and the two end terminals are each

connected to the ”SMA~D” terminals of the ECM.

The voltage of the ”SMA~D” terminals of the ECM is

under 1 V when connected, and otherwise is the bat-

tery voltage.

Loading...

Loading...