90

NOTE:

Prior to checking oil pressure, check the following.

Oil level in oil pan.

If level is low, add oil to Full level line on oil

dip stick.

Oil quality.

If oil is discolored, or deteriorated, change

oil. For particular oil to be used , refer to

table in SECTION 1.

Oil leak.

If oil leak is found, repair it.

1) Disconnect lead wire from oil pressure switch.

2) Remove oil pressure switch from cylinder block.

3) Install oil pressure gauge (special tool) in vacated

threaded hole.

4) Start engine and warm it up to normal operating tem-

perature.

5) After warming up, raise engine speed to 4,000 RPM

and measure oil pressure.

Oil pressure specification

2.7–3.7 kg/cm2

38.4–52.6 psi

at 4,000 RPM

6) After checking oil pressure, stop engine and remove

oil pressure gauge.

7) Before reinstalling oil pressure switch, be sure to wrap

its screw threads with sealing tape and tighten switch to

specified torque.

Tightening torque for oil

pressure switch

12–15 N–m

1.2–1.5 kg–m

9.0–10.5 lb–ft

NOTE:

If sealing tape edge is bulged out from screw

threads of switch, cut off edge.

8) After installing oil pressure switch, start engine and

check switch for oil leakage.

Vacuum Measurement

Engine vacuum that develops in intake line is a good indi-

cator of engine condition. Vacuum checking procedure

is as follows:

1) Warm up engine to normal operating temperature.

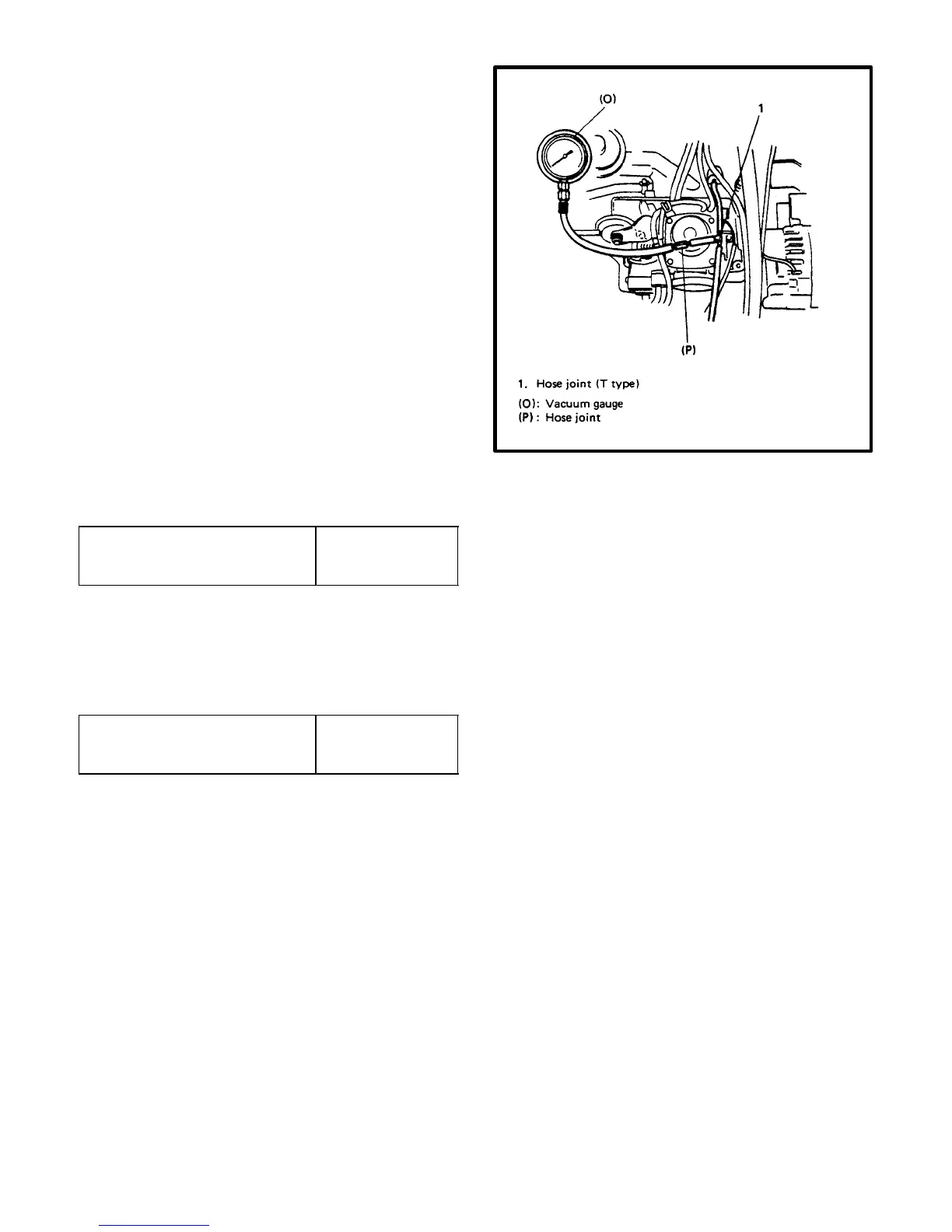

2) Install vacuum gauge (O) to pressure sensor hose, as

shown in figure below. Install engine tachometer.

3) Run engine at specified idling speed and under this

running condition, read vacuum gauge. Vacuum should

be between 40cmHg (15.8 in.Hg) and 48 cmHg (18.8

in.Hg).

A low vacuum reading means that any combination of the

following malconditions is the cause, which must be cor-

rected before releasing machine to customer.

a) Leaky cylinder head gasket

b) Leaky intake manifold gasket

c) Leaky valves

d) Weakend valve springs

e) Maladjusted valve clearance

f) Valve timing out of adjustment

Loading...

Loading...