4

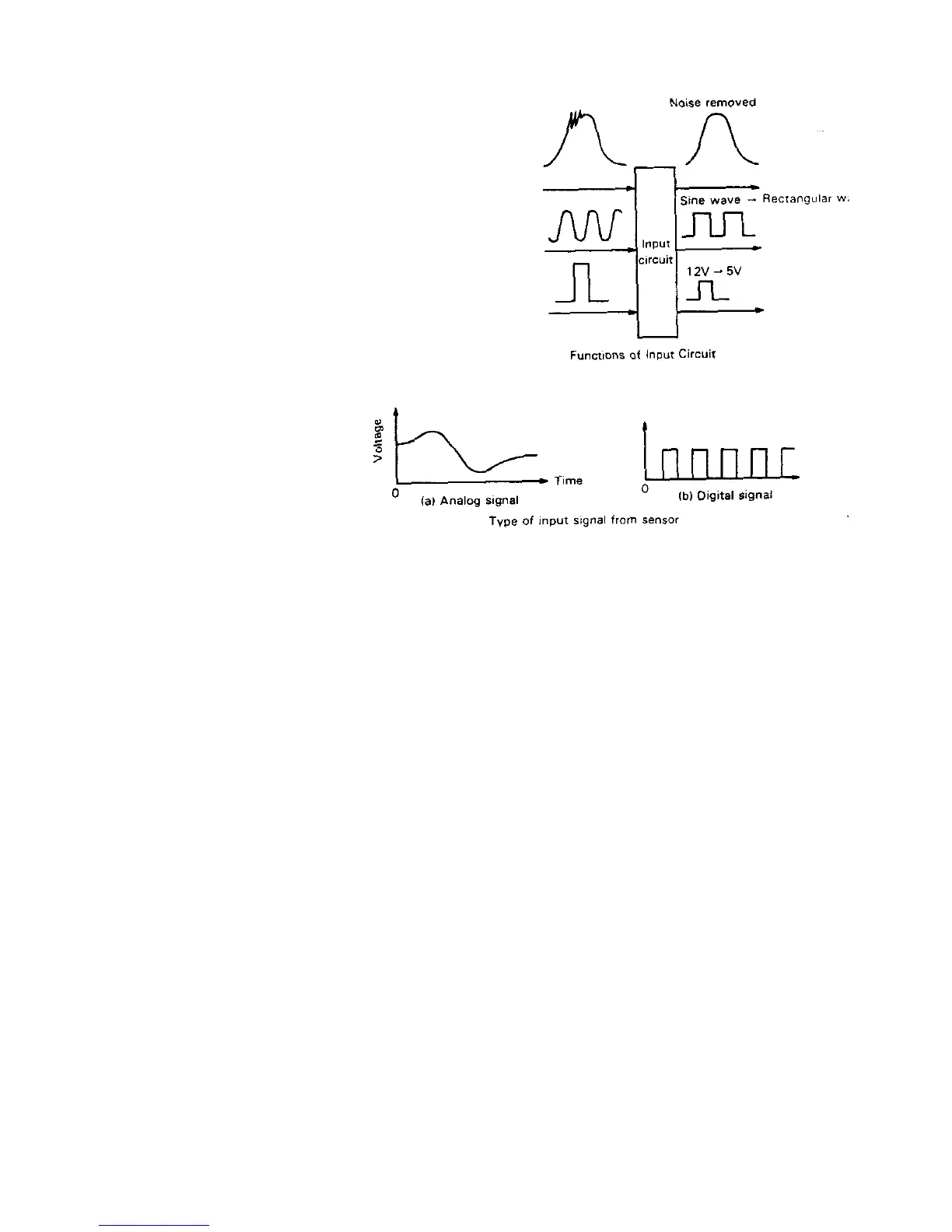

Input circuit

When a signal from each sensor enters ECM, it first passes

through the input circuit, where any noise on each signal is

removed and a sine wave signal such as a crank angle signal is

converted to a pulse signal (rectanglar wave). Another function of

the input circuit is to convert the voltage level of the digital signal

to such voltage level that can be processed by the microcom-

puter which operates at a 5V voltage.

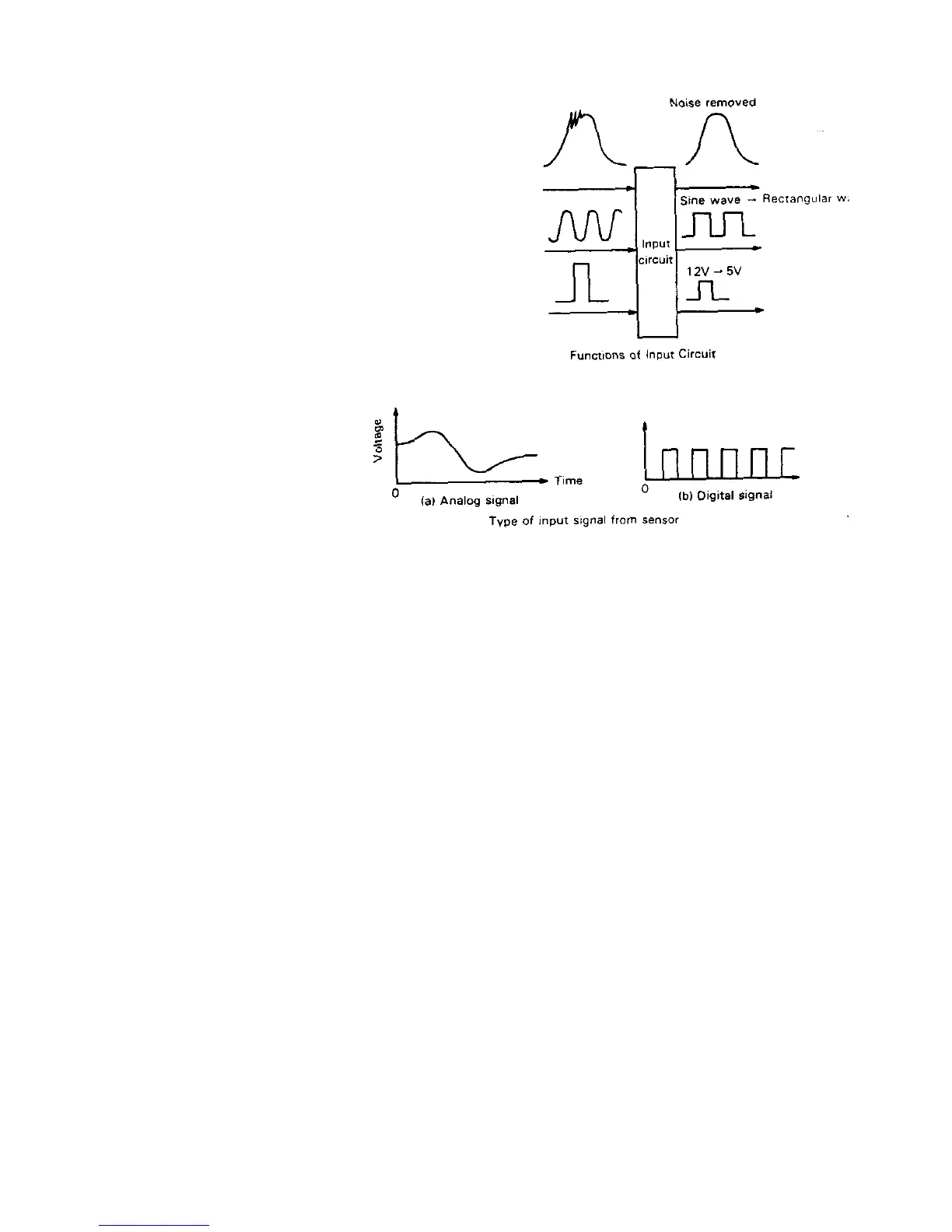

A/D Converter

The analog signal received by the ECM

must be converted into a digital signal

for microcomputer processing and this

conversion is done by the A/D con-

verter.

Microcomputer

The microcomputer accepts signals from the sensors as necessary, processes them by using programs and data written

in it and then sends the results to the output circuit as fuel injection signals, ignition signals, etc. Here each of its compo-

nents is described.

(1) CPU

CPU is the brain of the microcomputer. It processes the input data by using the processing program stored in the ROM.

In the CPU, simultaneous processing of a large amount of data is not expected, for the data is processed one by one

within each unit time. However, as the processing speed is as high as to handle over one million operations per second, it

can process a large amount of data very quickly.

(2) Memory (ROM, RAM)

The ROM (Read–Only Memory) is where programs and data necessary for control are stored. Once stored in it, they are

retained as they are, even if power has been turned OFF and no change can be made to them.

The RAM (Random Access Memory) is where input data and processed results are temporarily stored. They will be

erased if power is turned OFF.

(3) Input/output interface

The input/output interface controls receiving and sending signals according to the command from CPU. As CPU cannot

process a large amount of data simultaneously as described above, inputting/ outputing of signals is executed according

to the programmed sequence.

Output circuit

As the output signal from the microcomputer is a digital signal, it cannot operate the actuator. The output circuit has a

function to operate the actuator, based on the output signal from the microcomputor.

Loading...

Loading...