74

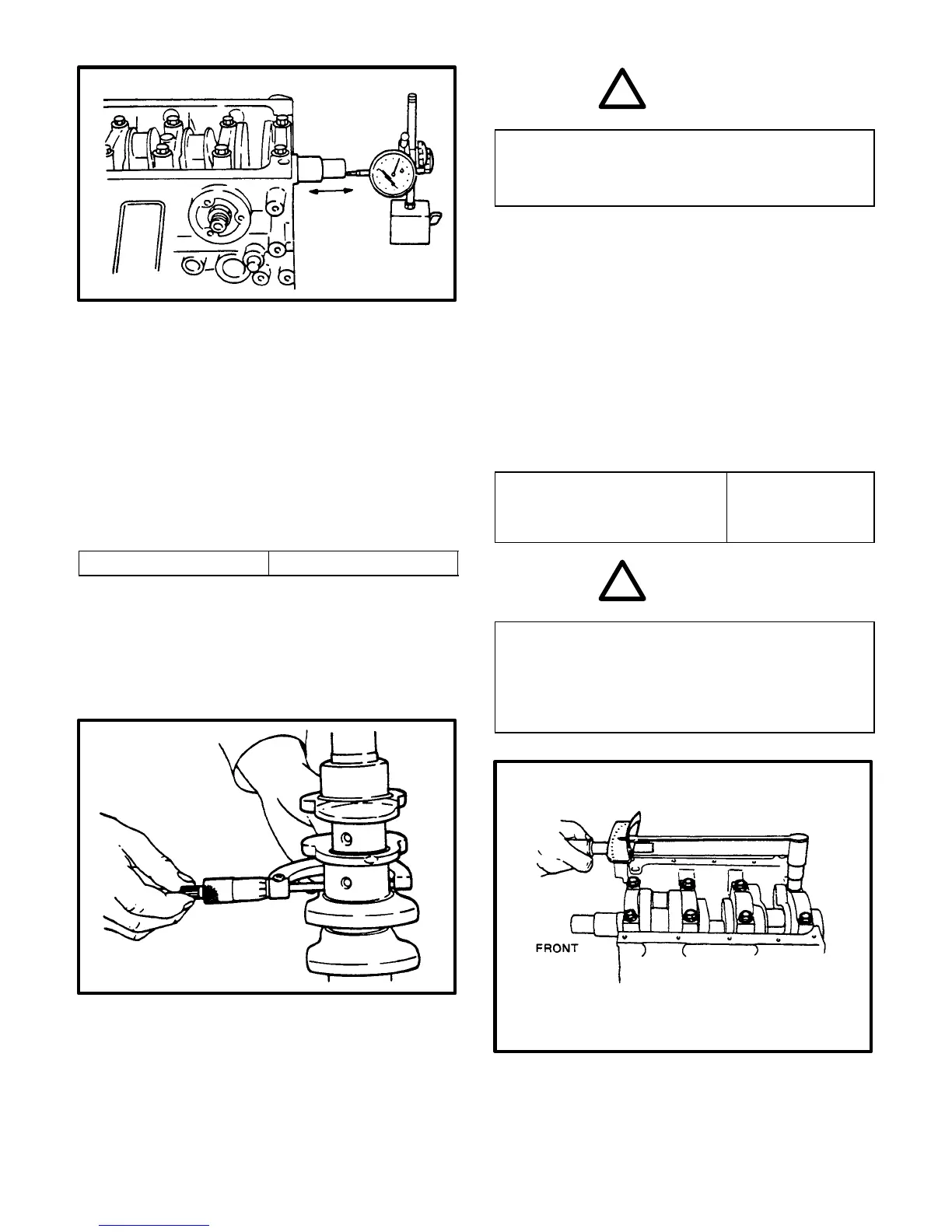

Out of round and taper (uneven wear):

An unevenly worn crankshaft journal or crankpin

shows up as difference in diameter at a cross

section or along its length (or both). This differ-

ence, if any, is to be determined from micrometer

readings taken as shown in figure below.

If any of the journals or crankpins is badly dam-

aged or if the amount of uneven wear in the

sense explained above exceeds the limit, repair

(by re–grinding) or replace the crankshaft.

Limit or uneven wear 0.01 mm (0.0004 in.)

NOTE:

Where journal or crankpin re–grinding is necessary,

finish the diameter to the size necessary for the

undersize bearing.

Crankshaft Journal Bearings

Inspect the bearings for signs of fusion, pitting,

burn or flaking and observe the contact pattern.

Defective bearings must be replaced.

CAUTION

!

As in the case of connecting rod bearings, the

journal bearings are not meant to be repaired by

scraping or sanding with sandpaper or by any

other machining.

Journal to bearing clearance:

Check this clearance by using gaging plastic

(Plastigage). The following method is based on

the use of gaging plastic:

1) Cut the gaging plastic stock to the required

length (equal to the width of the bearing), and

place it axially on the journal, avoiding the oil

hole.

2) Mount the crankshaft in usual manner, tight-

ening the bearing caps to the specified torque

value. (It is assumed that a gaging plastic piece

is pinched at each journal.) Do not rotate the

crankshaft when gaging plastic is in,

Tightening torque for cap

bolts

55–60 N–m

5.5–6.0 kg–m

40.0–43.0 lb–ft

CAUTION

!

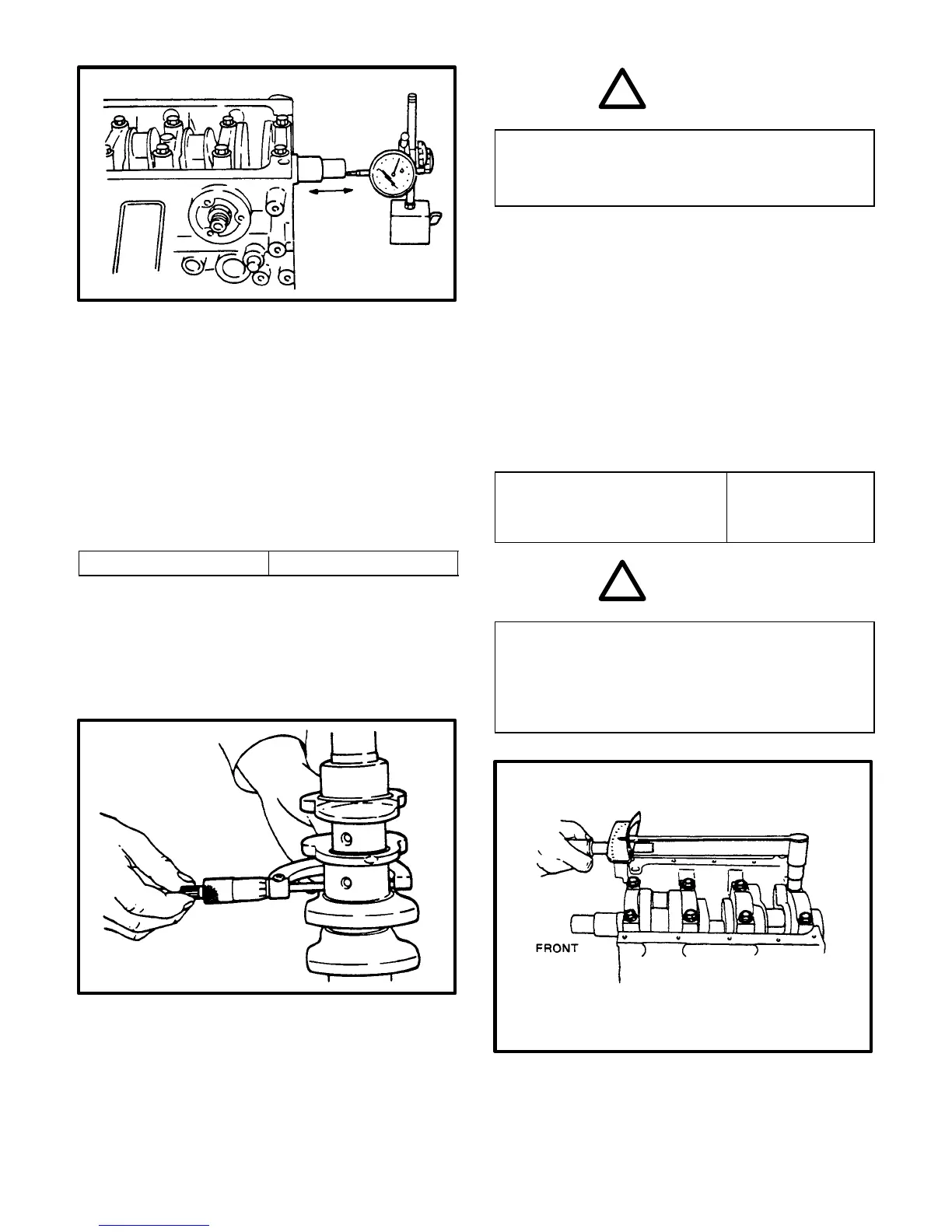

Each of the four bearing caps has an arrow

marked on it. Be sure to position each cap with

its arrow pointing to front end and to match it

(by the cylinder number) to its journal. Remem-

ber, the three cylinders are numbered, 1, 2, and

3, as counted from the front of engine.

3) Remove the caps. By referring to the envelope scale,

measure the width of the widest part of the piece, and

determine whether the radial clearance checked (obtain

from the gaging plastic piece) is within the limit.

Loading...

Loading...