73

4) If the limit, indicated above, is exceeded, re–grind the

crankpin to the undersize and use of the undersize bear-

ing, both of which are stated below:

Bearing

size

Crankpin diameter

Standard

35.982–36.000 mm

(1.4167–1.4173 in.)

0.25 mm

(0.0098 in.)

undersize

35.732–35.750 mm

(1.4068–1.4074 in.)

0.50 mm

(0.0196 in.)

undersize

35.482–35.500 mm

(1.3970–1.3976 in.)

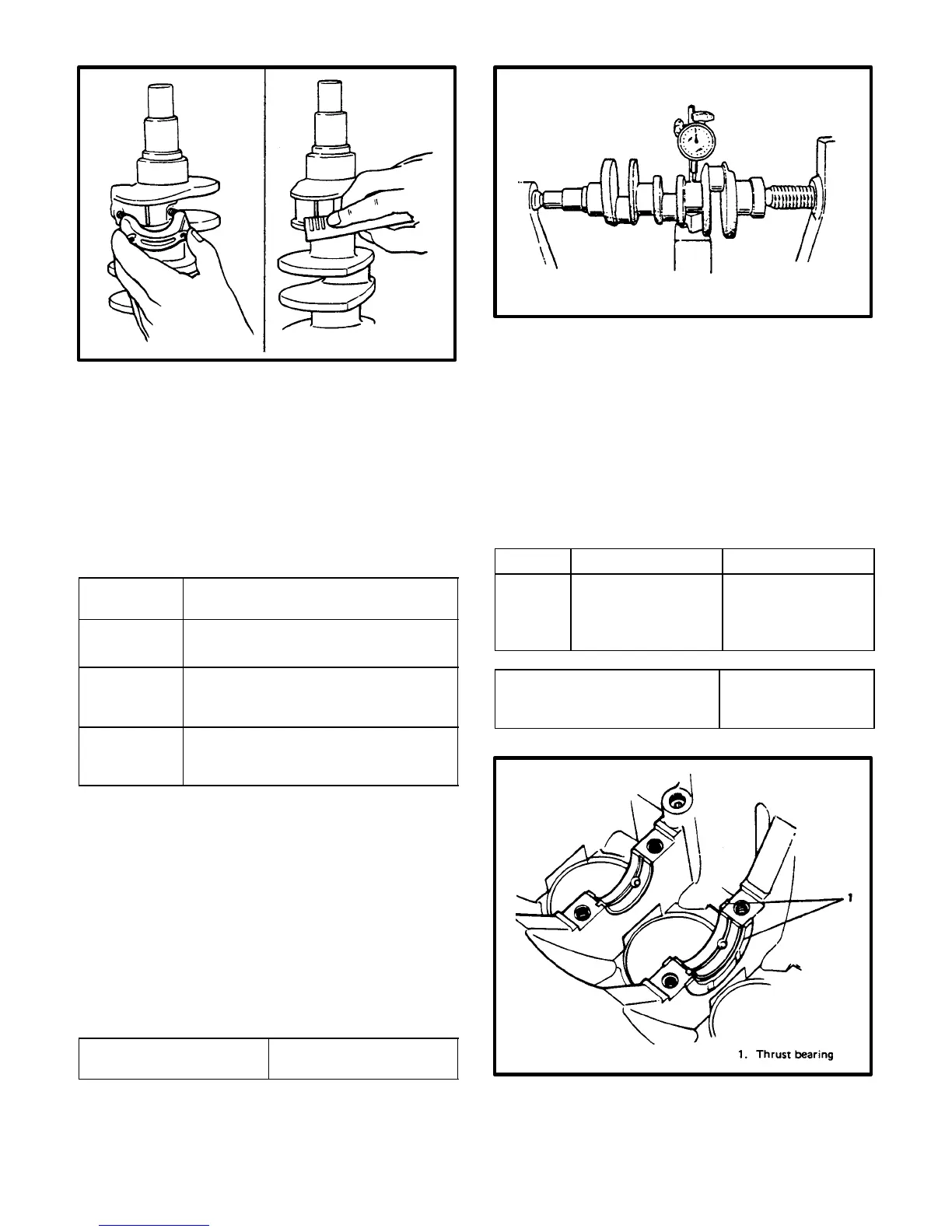

Crankshaft

Runout:

Using a dial gauge, measure runout at center

journal. Rotate crankshaft slowly, if runout

exceeds limit, replace crankshaft.

Limit on crankshaft

runout

0.03 mm (0.0011 in.)

Crankshaft thrust play:

Measure this play with crankshaft set in cylinder

block in the normal manner, that is, with thrust

bearing caps installed. Tighten bearing cap

bolts to specified torque.

Use a dial gauge to read displacement in axial

(thrust) direction of crankshaft.

If the limit is exceeded, replace thrust bearing

with new standard one or oversize one to obtain

standard thrust play.

Item Standard Limit

Crank-

shaft

thrust

play

0.11–0.31 mm

(0.0044–0.0122 in.)

0.35 mm

(0.0138 in.)

Tightening torque for cap

bolts

55–60 N–m

5.5–6.0 kg–m

40.0–43.0 lb–ft

Loading...

Loading...