167

See your authorized CUSHMAN dealer for nec-

essary maintenance and service.

• When replacement parts are required, use genu-

ine CUSHMAN parts or parts with equivalent

characteristics including type, strength and

material. Failure to do so may result in product

malfunction and possible injury to the operator

and/or bystanders.

• Immediately replace any warning decal that

becomes hard to read.

MAINTENANCE GUIDE

The guide is set up for average use on clean, paved sur-

faces. Vehicles used in dusty areas, for winter driving or

in wet, snowy or muddy conditions require more frequent

service.

AS REQUIRED

Check tire pressure

Check self adjusting brakes

EVERY 200 HOURS OF OPERATION

Perform previous Services

Lubricate all grease fittings *

Check differential oil level **

EVERY 1000 HOURS OR YEARLY

Perform previous Services

Change differential oil **

Clean and repack front wheel bearings

* Refer to the lubrication chart.

** The differential oil must be changed after the FIRST

100 hours or 1000 miles of service.

BRAKE FLUID

Use type Dot (3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access to the master cylinder is through the opening in

the floorboard in front of the operators seat.

LUBRICATING BRAKE PEDAL BUSHING

The brake pedal pivot bushing lubrication fitting is

located just below the hole in the floorboard, near the

brake pedal. See Figure 5.

Pedal Lubrication Access Hole

FIGURE 5

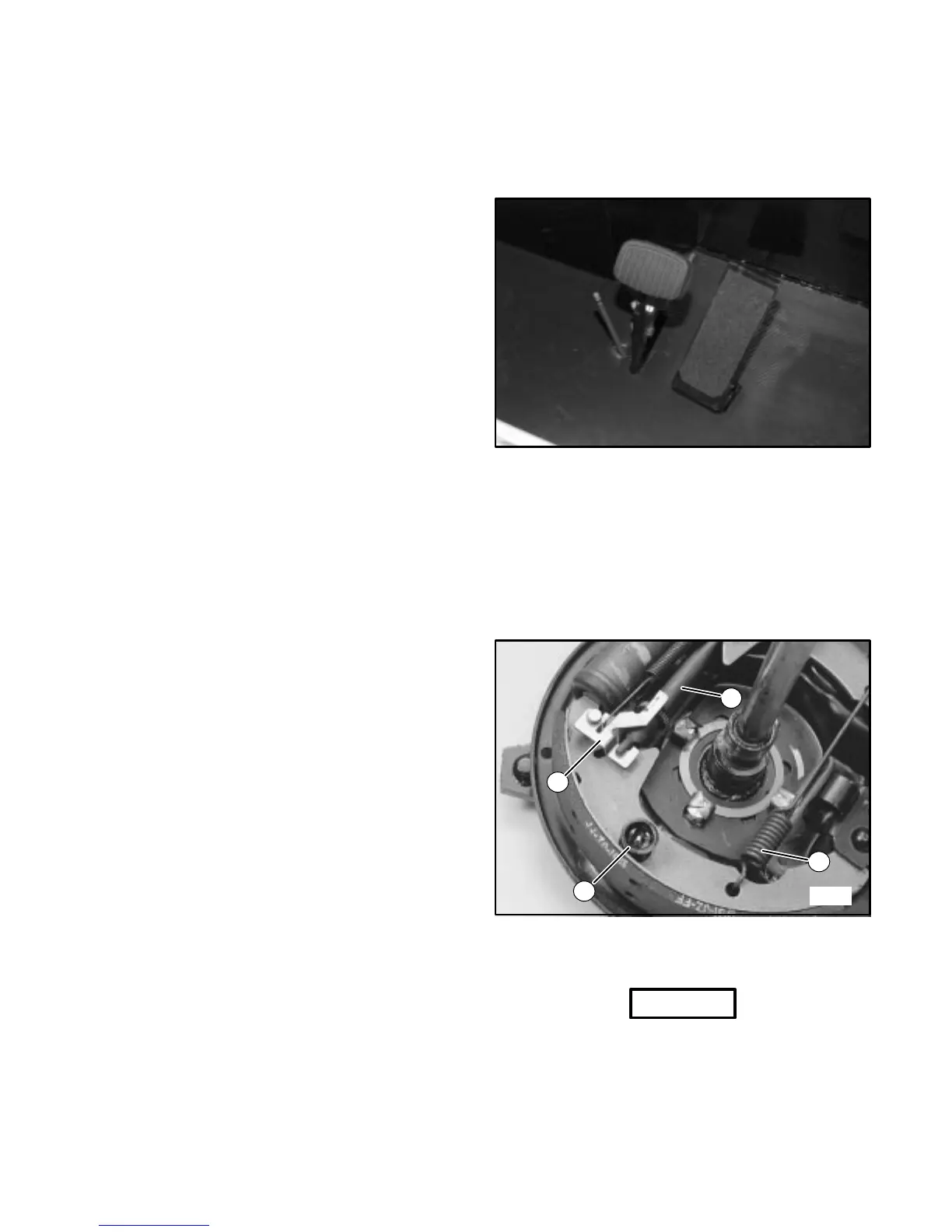

BRAKE SHOE REPLACEMENT

1. Remove the front wheel and hub assembly.

2. Disconnect both return springs from shoe assembly

and brake lever. Remove shoe retainers. Remove

brake lever and adjuster. Care must be taken not to

disturb the hydraulic wheel cylinder. Remove the

brake shoes from the backing plate. See Figure 6.

1

2

3

4

4406

FIGURE 6

1. Brake Lever 3. Return Springs

2. Shoe Retainers 4. Brake Adjuster

NOTICE

• DO NOT press the brake pedal while the brake is dis-

assembled.

• Examine the wheel cylinder for leaks before reas-

sembly by carefully pulling back each rubber boot on