80

3) Install piston and connecting rod assembly into cylin-

der bore.

Apply engine oil to pistons, rings, cylinder walls,

connecting rod bearings and crank pins.

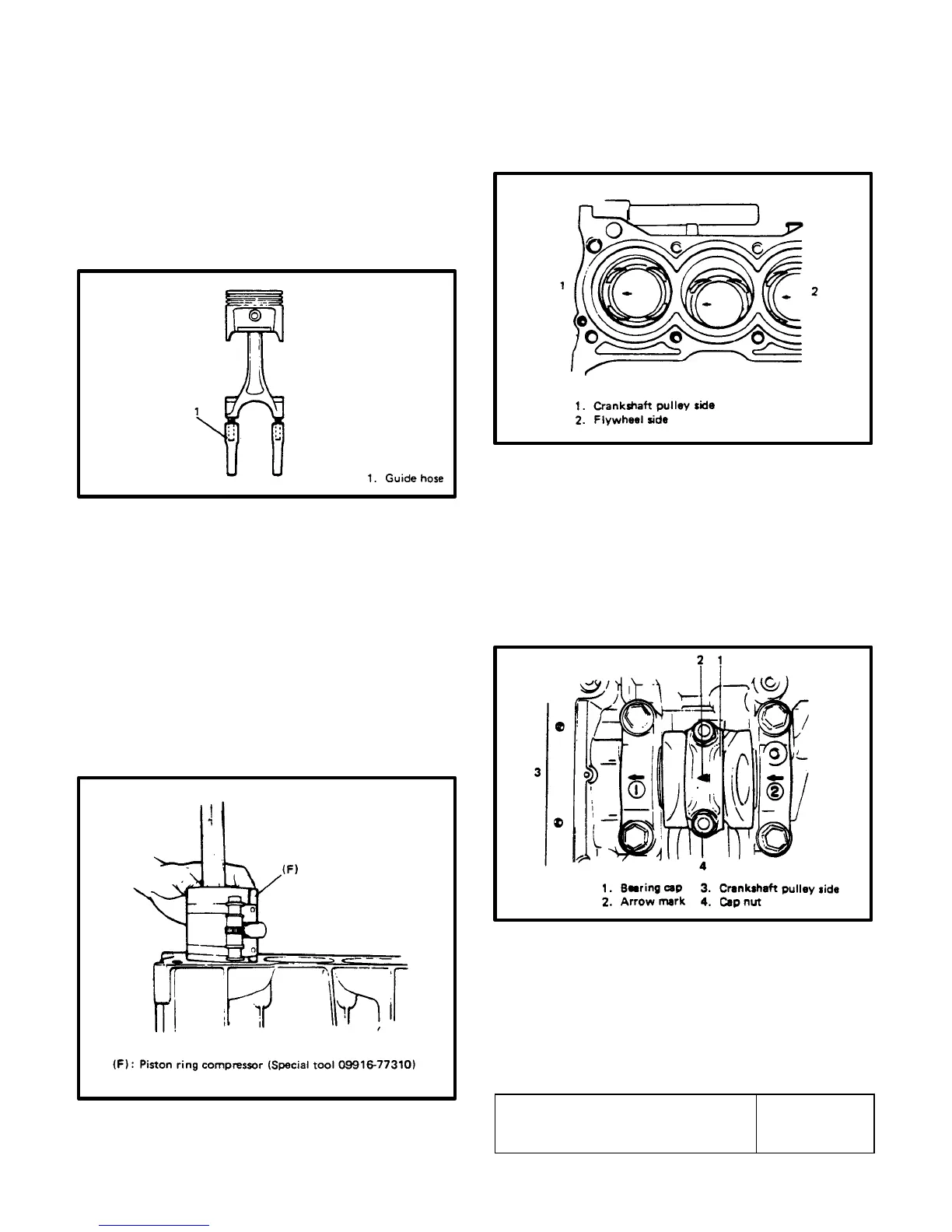

Put guide hoses over connecting rod bolts as

shown. These guide hoses protect crankpin and

thread of rod bolt from damage during installa-

tion of connecting rod and piston assembly.

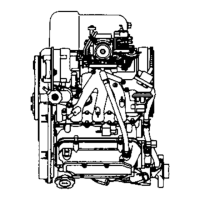

When installing piston and connecting rod

assembly into cylinder bore, point arrow mark on

each piston head to crankshaft pulley side.

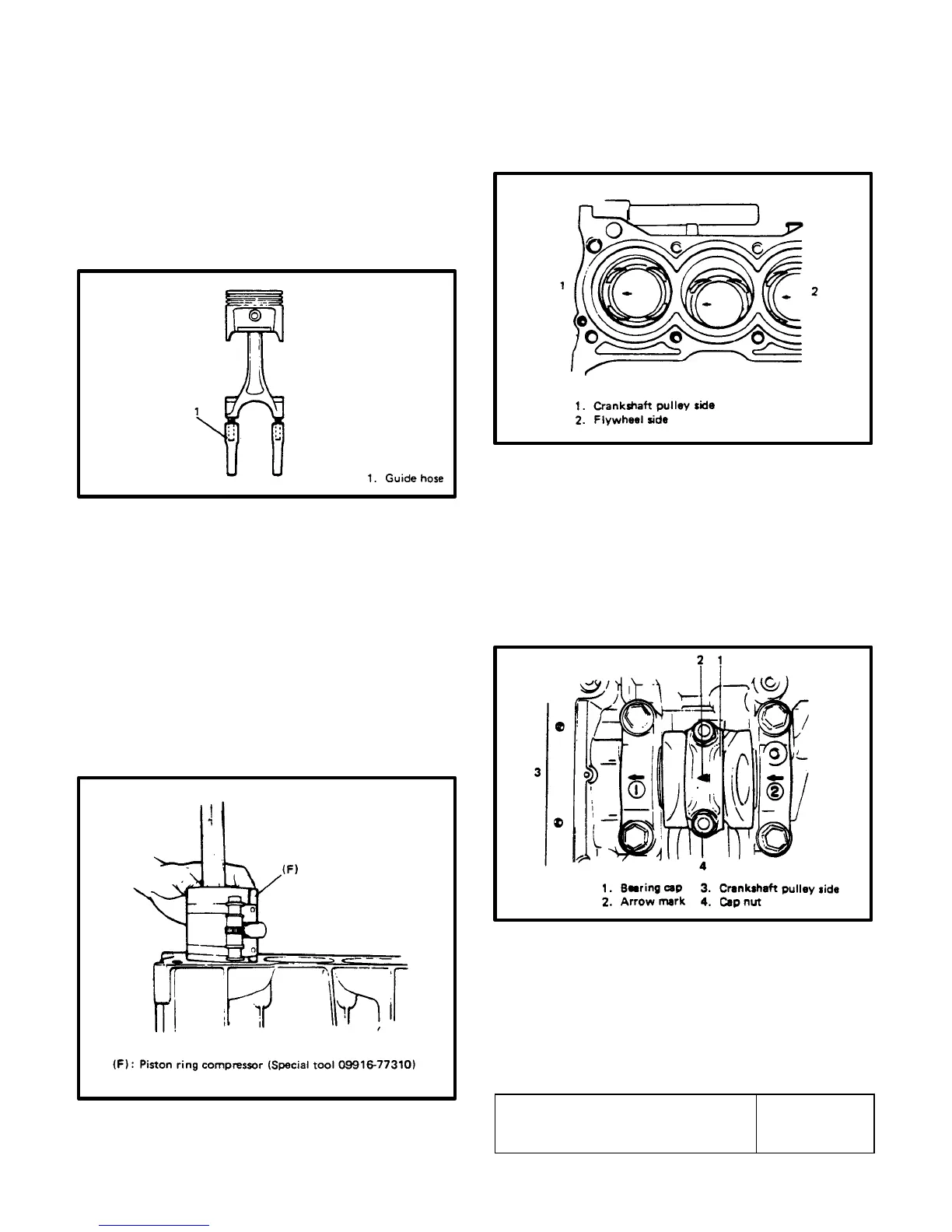

Use piston ring compressor (Special tool) to

compress rings. Guide connecting rod into

place on the crankshaft.

Using a hammer handle, tap piston head to

install piston into bore. Hold ring compressor

firmly against cylinder block until all piston rings

have entered cylinder bore.

NOTE:

After installing piston and connecting rods,

double–check to be sure that the arrows on piston

crowns are all pointing to pulley (front) side.

Apply engine oil to crankpins.

4) Install connecting rod bearing cap.

When installing cap to rod, point arrow mark on cap to

crankshaft pulley side.

Tighten cap nuts to specification

After fitting all three big–end bearing caps, start tighten-

ing them uniformly, being sure to equalize tightness

between right and left on each cap. The sequence here

is similar to that for crankshaft bearing caps.

Tightening torque for big–end

caps

31–35 N–m

3.1–3.5 kg–m

22.5–25.0 lb–ft

Loading...

Loading...