3-10

OPERATION

CRAWLER WIDTH SWITCHING

Operate the machine with the maximum

crawler width

• Always operate the machine with the

crawler width extended to 1500 mm

(59.1 in.) to maximize the machine

stability. If the machine is operated with

the crawler width narrowed (1100 mm,

43.3 in.), the machine may tip over due

to its poor stability.

• If the machine must be operated with

the narrowed crawler width (1100 mm,

43.3 in.), traveling should be done after

folding the hoe attachment, lowering the

boom to lower the center of gravity and

keeping the machine facing forward.

IMPORTANT: All debris, mud, soil, stones,

etc. must be removed from the track

frame before switching the crawler width.

Do it in a safe manner and do not work

under the machine.

This machine is able to change the crawler

width. Normally, it is best to operate with the

crawler width extended for machine’s

stability.

Switching the crawler width

Perform the operation on a flat and rigid

ground where no obstacles around.

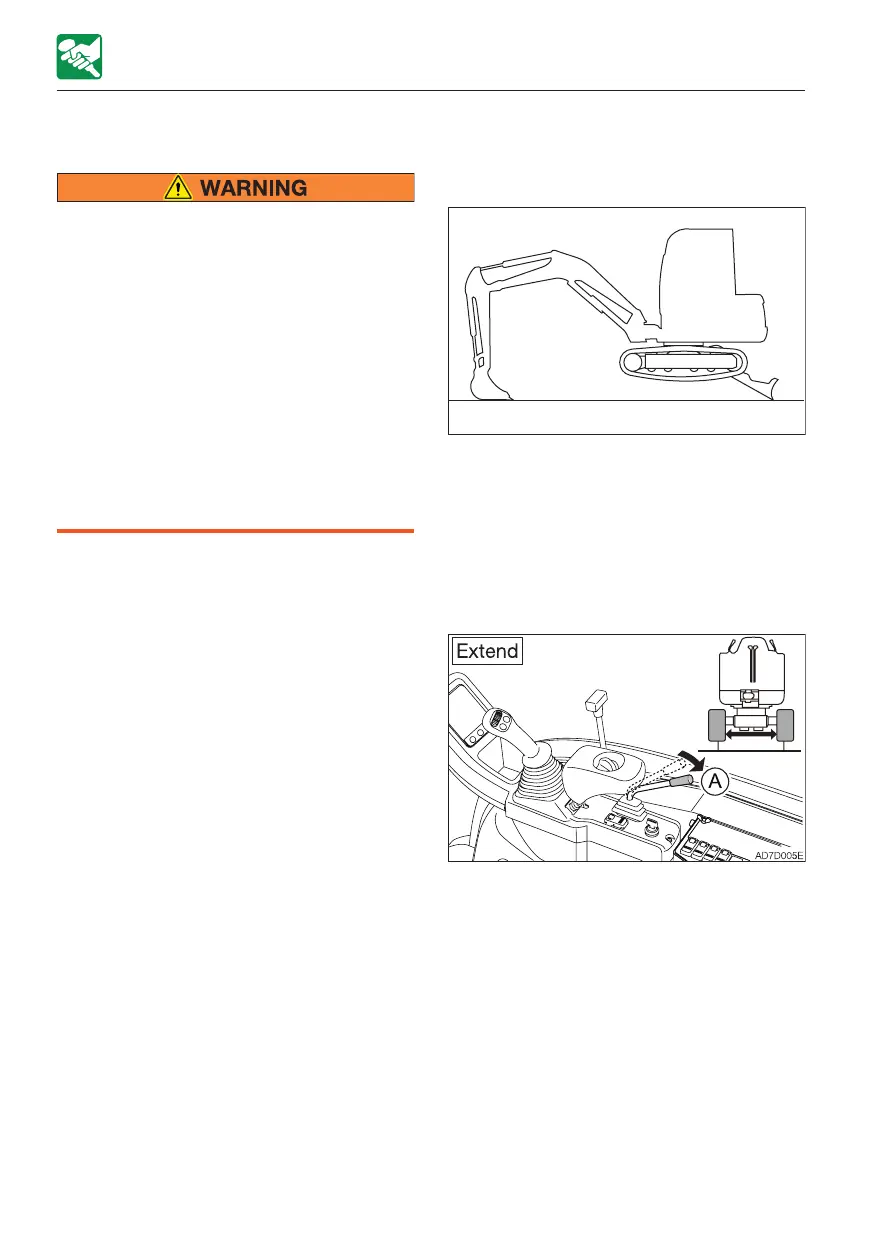

2. Turn the crawler width switch lever in the

direction of “A” to increase the crawler

width (1500 mm or 59.1 in.).

If necessary, extend the blade width by

changing the plate (2).

Refer to “Switching the blade width” on

page 3-11.

OPERATING THE MACHINE

1. Raise the machine body by using the hoe

attachment and the dozer blade.

IMPORTANT: Be sure to raise the machine

body before switching the crawler width.

If the operation is attempted when the

crawler is rested on the ground, the travel

frame or span cylinder may be damaged.

Loading...

Loading...