1-14

SAFETY

Ensure good visibility

Check the field of view before operating the

machine.

• When working in dark places, turn on the

machine’s working lights and headlights

and additional lighting equipment installed,

as necessary.

• When visibility is poor due to bad weather

(fog, snow, rain or a cloud of dust), stop

operating the machine and wait until

visibility improves.

• Clean the windows, mirrors, lights and

camera to ensure good visibility. Adjust the

mirror and camera to the best positions so

that the operator can see the rear view

(blind spots) from the operator’s seat.

• Unauthorized machine modifications or

installation of unapproved attachments

could impair the visibility. The operator’s

field of view must conform to ISO 5006.

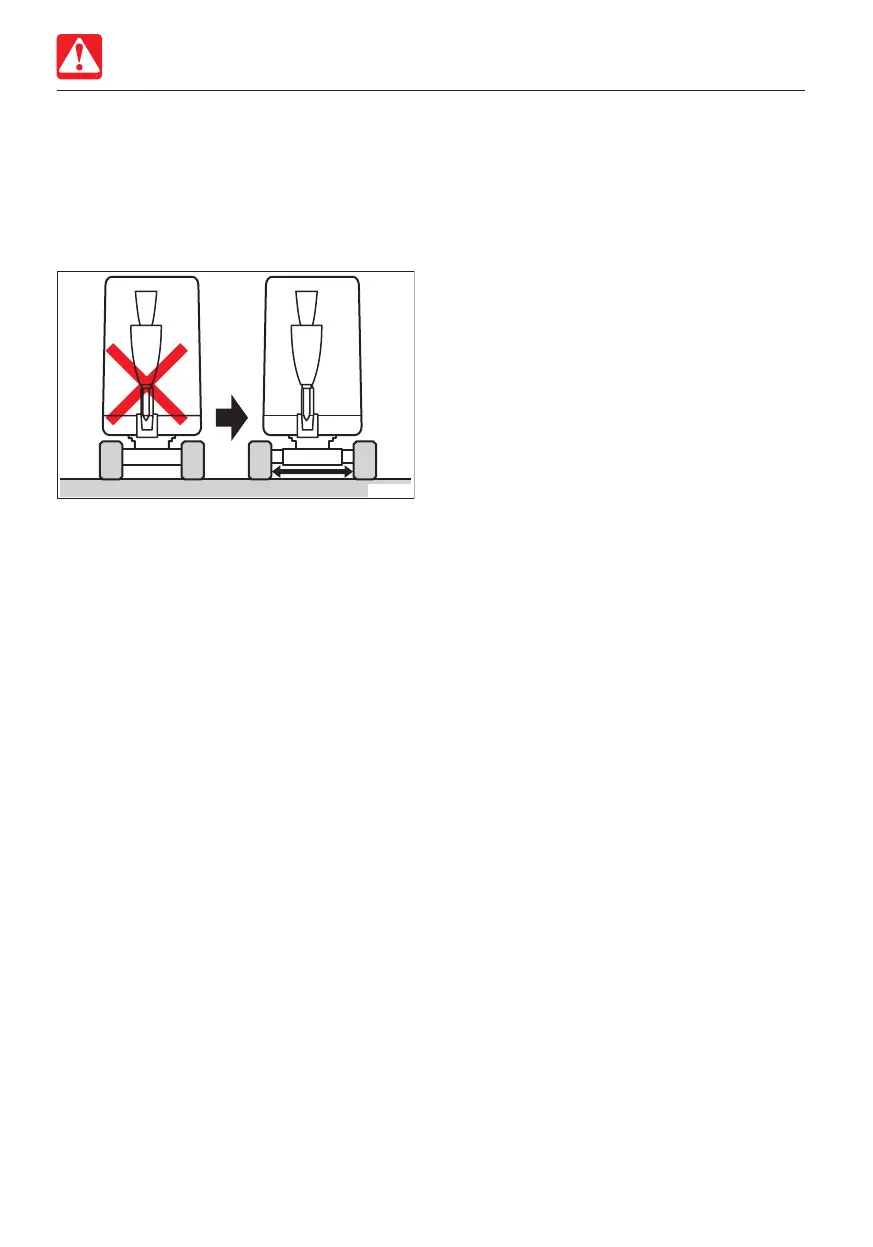

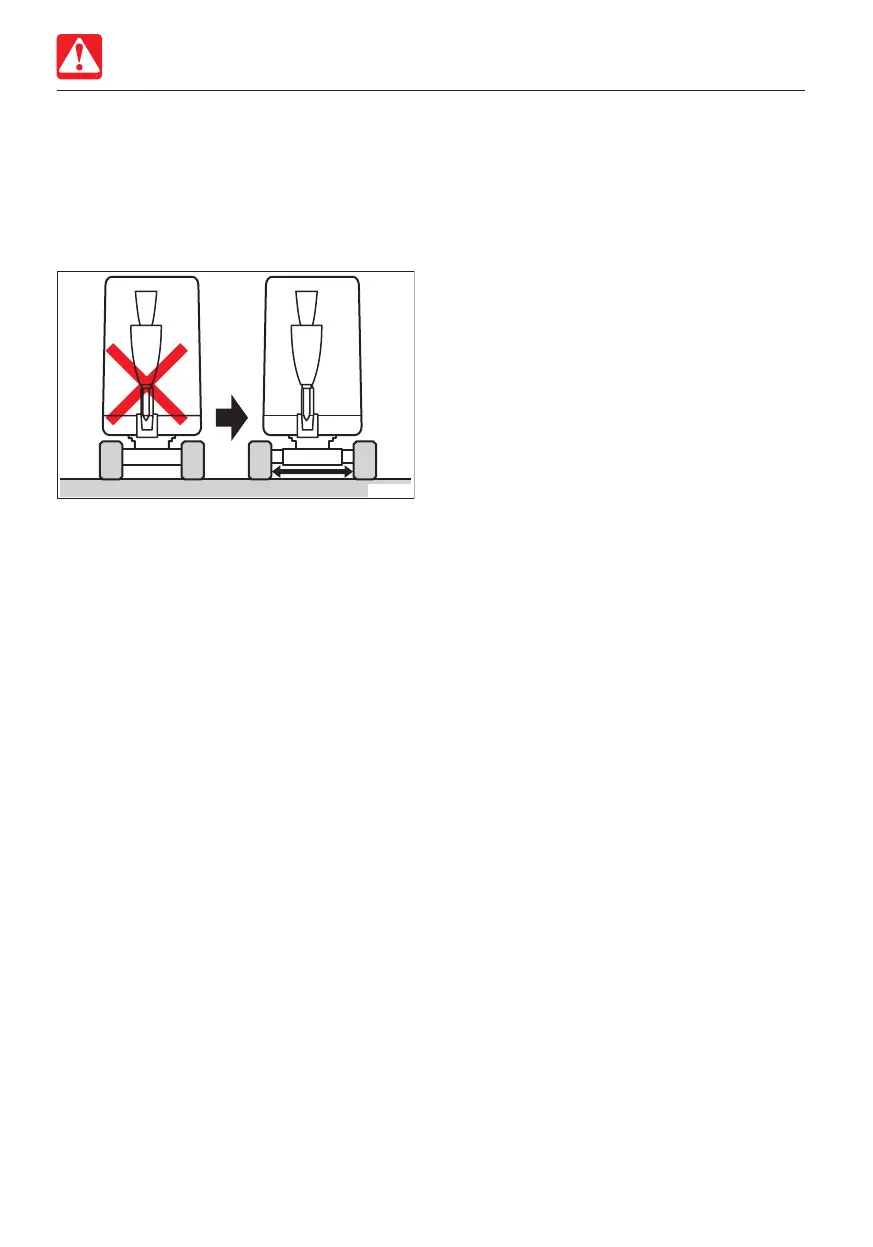

PRECAUTIONS WHEN OPERATING

PRECAUTIONS WHEN

OPERATING

Operate the machine with the maximum

crawler width

• Always operate the machine with the

crawler width extended to 1500 mm (59.1

in.) to maximize the machine stability. If the

machine is operated with the crawler width

narrowed 1100 mm (43.3 in.), the machine

may tip over due to its poor stability.

• If the machine must be operated with the

narrowed crawler width 1100 mm (43.3 in.),

traveling should be done after folding the

hoe attachment, lowering the boom to

lower the center of gravity and keeping the

machine facing forward.

Loading...

Loading...