Performance Check Procedure—2205 Service

TRIGGER

Equipment Required (See Table 4-1):

Leveled Sine-Wave Generator (item 2)

Dual-Input Coupler (Itehrt T)

50-D Coaxial Cable (Item 6)

50-n Termination (Item 8)

INITIAL CONTROL SETTINGS

Vertical

POSITION (both)

MODE

Midrange

CH 1, NORM

CH 1 VOLTS/DIV

0.1 V

CH 2 VOLTS/DIV 1 V

VOLTS/DIV Variable (both)

CAL detent

AC-GND-DC (both)

DC

Horizontal

POSITION (COARSE and FINE) Midrange

MAG XI

SEC/DIV 0.2 ms

SEC/DIV Variable CAL detent

■Trigger-1-1'"'''''''''';'1"'

SLOPE Positive <-/-)

LEVEL Midrange

- MODE ' ' ■ P-P AUTO

SOURCE VERT MODE

PROCEDURE STEPS

1. Check Internal Triggering

a. Connect the leveled sine-wave generator out

put via a 50-n coaxial cable and a 50-n termination

to the CH 1 o r X input connector.

b. Set the generator to produce a 3-division

display at an output frequency of 5 MHz.

c. Set channel 1 VOLTS/DIV switch to 1 V.

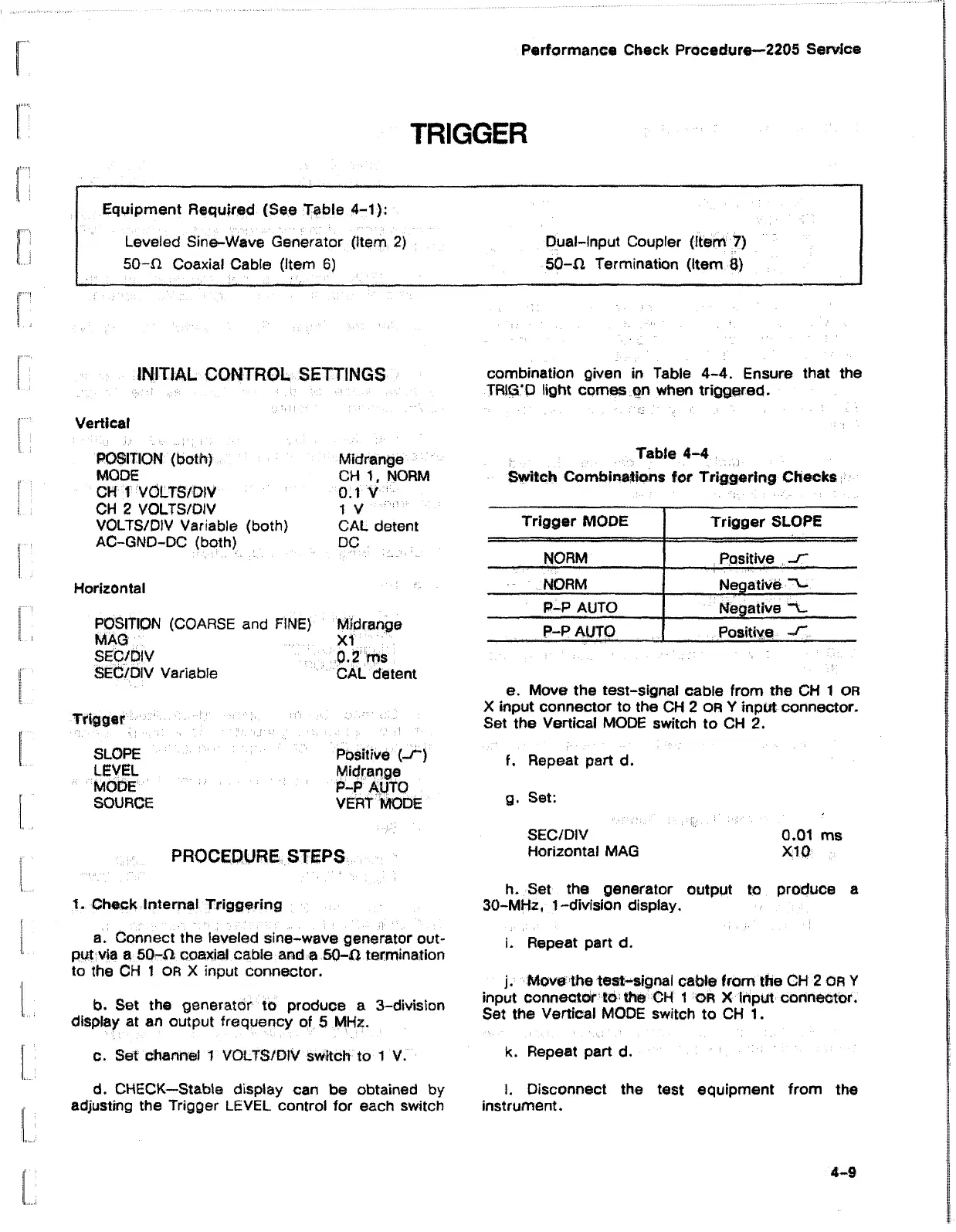

combination given in Table 4-4. Ensure that the

TRIG'D light comes on when triggered.

Table 4-4

Switch Combinations for Triggering Checks

Trigger MODE

Trigger SLOPE

NORM

Positive -T

NORM

Negative “V.

P-P AUTO

Negative “V.

P-P AUTO

Positive

e. Move the test-signal cable from the CH 1 OR

X input connector to the CH 2 OR Y input connector.

Set the Vertical MODE switch to CH 2.

f. Repeat part d.

g. Set:

SEC/DIV 0.01 ms

Horizontal MAG X10

h. Set the generator output to produce a

30-MHz, 1 -division display.

i. Repeat part d.

j. Move the test-signal cable from the CH 2 or Y

input connector to the CH 1 or X Input connector.

Set the Vertical MODE switch to CH 1.

k. Repeat part d.

d. CHECK—Stable display can be obtained by 1. Disconnect the test equipment from the

adjusting the Trigger LEVEL control for each switch instrument.

4-8

Loading...

Loading...