Maintenance-2205 Service

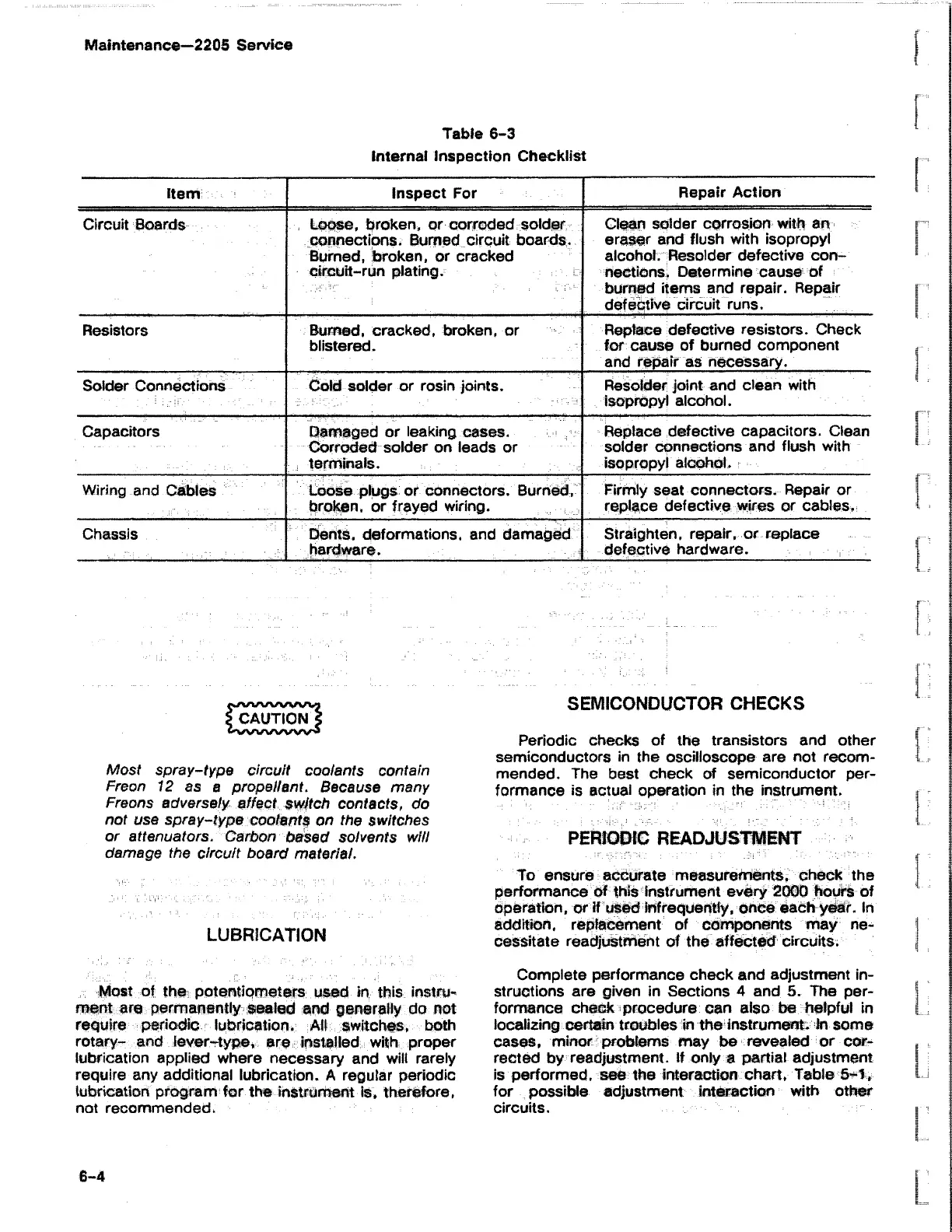

Table 6-3

internal Inspection Checklist

Item

Inspect For

Repair Action

Circuit Boards

Loose, broken, or corroded solder

connections. Burned circuit boards.

Burned, broken, or cracked

circuit-run plating.

Clean solder corrosion with an

eraser and flush with isopropyl

alcohol. Resolder defective con

nections. Determine cause of

burned items and repair. Repair

defective circuit runs.

Resistors

Burned, cracked, broken, or

blistered.

Replace defective resistors. Check

for cause of burned component

and repair as necessary.

Solder Connections Cold solder or rosin joints.

Resolder joint and clean with

Isopropyl alcohol.

Capacitors

Damaged or leaking cases.

Corroded solder on leads or

: terminals.

Replace defective capacitors. Clean

solder connections and flush with

isopropyl alcohol.

Wiring and Cables

Loose plugs or connectors. Burned,

broken, or frayed wiring.

Firmly seat connectors. Repair or

replace defective wires or cables.

Chassis Dents, deformations, and damaged

hardware.

Straighten, repair, or replace

defective hardware.

SEMICONDUCTOR CHECKS

Periodic checks of the transistors and other

semiconductors in the oscilloscope are not recom

mended. The best check of semiconductor per

formance is actual operation in the instrument.

PERIODIC READJUSTMENT

To ensure accurate measurerrienfs. check the

performance of this instrument every 2000 hours of

operation, or if used infrequently, once each year. In

addition, replacement of components may ne

cessitate readjustment of the affected circuits.

Complete performance check and adjustment in

structions are given in Sections 4 and 5. The per

formance cheek procedure can also be helpful in

localizing certain troubles in the instrument. In some

cases, minor problems may be revealed or cor

rected by readjustment. If only a partial adjustment

is performed, see the interaction chart, Table 5-1,

for possible adjustment interaction with other

circuits.

aAIWWVVVi

i CAUTION 5

w vw w v w S

Most spray-type circuit coolants contain

Freon 12 as a propellant. Because many

Freons adversely affect switch contacts, do

not use spray-type coolants on the switches

or attenuators. Carbon based solvents will

damage the circuit board material.

LUBRICATION

Most of the potentiometers used in this instru

ment are permanently sealed and generally do not

require periodic lubrication. All switches, both

rotary- and lever-type, are installed with proper

lubrication applied where necessary and wilt rarely

require any additional lubrication. A regular periodic

lubrication program for the instrument is, therefore,

not recommended.

6-4

Loading...

Loading...