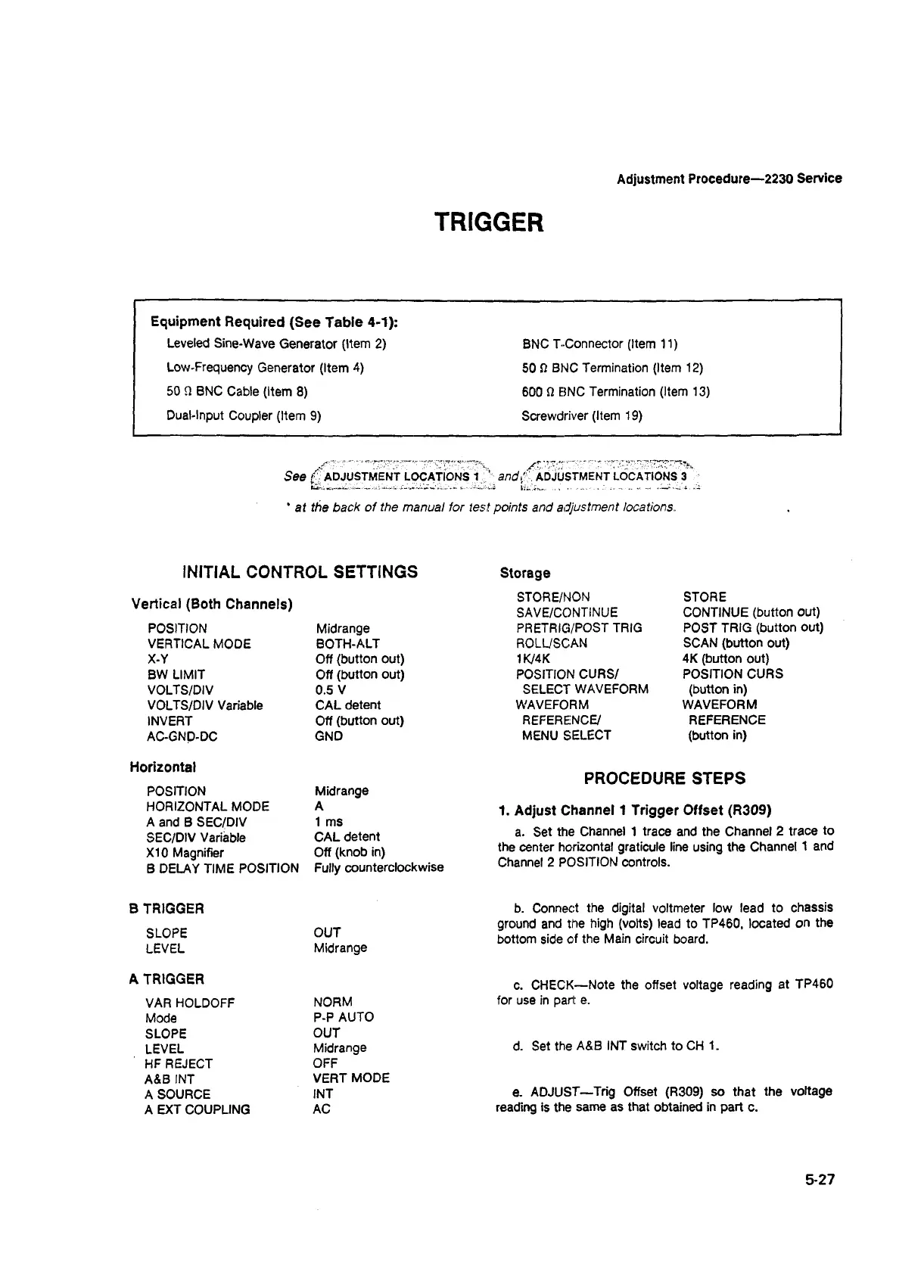

TRIGGER

Adjustment Procedure—2230 Service

Equipment Required (See Table 4-1):

Leveled Sine-Wave Generator (Item 2)

BNC T-Connector (Item 11)

Low-Frequency Generator (Item 4)

50 Si BNC Termination (Item 12)

50 0 BNC Cable (Item 8)

600 fl BNC Termination (Item 13)

Dual-Input Coupler (Item 9) Screwdriver (Item 19)

See f" ADJUSTMENT LOCATIONS 1 ' andifjADJUSTMENT LOCATIONS 3

* at the back of the manual for test points and adjustment locations.

INITIAL CONTROL SETTINGS Storage

Vertical (Both Channels)

POSITION Midrange

VERTICAL MODE

BOTH-ALT

x-v

Off (button out)

BW LIMIT Off (button out)

VOLTS/DIV 0.5 V

VOLTS/DIV Variable

CAL detent

INVERT

Off (button out)

AC-GND-DC

GND

Horizontal

POSITION Midrange

HORIZONTAL MODE

A

A and B SEC/DIV

1 ms

SEC/DIV Variable

CAL detent

XI0 Magnifier

Off (knob in)

B DELAY TIME POSITION

Fully counterclockwise

B TRIGGER

SLOPE

OUT

LEVEL

Midrange

A TRIGGER

VAR HOLDOFF

NORM

Mode

P-P AUTO

SLOPE

OUT

LEVEL

Midrange

HF REJECT

OFF

A&B INT

VERT MODE

A SOURCE

INT

A EXT COUPUNG

AC

STORE/NON

SAVE/CONTINUE

PRETRIG/POST TRIG

ROLL/SCAN

1K/4K

POSITION CURS/

SELECT WAVEFORM

WAVEFORM

REFERENCE/

MENU SELECT

PROCEDURE STEPS

1. Adjust Channel 1 Trigger Offset (R309)

a. Set the Channel 1 trace and the Channel 2 trace to

the center horizontal graticule line using the Channel 1 and

Channel 2 POSITION controls.

STORE

CONTINUE (button out)

POST TRIG (button out)

SCAN (button out)

4K (button out)

POSITION CURS

(button in)

WAVEFORM

REFERENCE

(button in)

b. Connect the digital voltmeter low lead to chassis

ground and the high (volts) lead to TP460, located on the

bottom side of the Main circuit board.

c. CHECK—Note the offset voltage reading at TP460

for use in pari: e.

d. Set the A&B INT switch to CH 1.

e. ADJUST—Trig Offset (R309) so that the voltage

reading is the same as that obtained in part c.

5-27