Maintenance—2465B/2467B Service

Deficiencies found that could cause personal injury or

could lead to further damage to the instrument should be

repaired immediately.

To prevent getting moisture inside the instrument

during external cleaning, use only enough liquid to

dampen the cloth or applicator.

CLEANING. Loose dust on the outside of the

instrument can be removed with a soft cloth or small soft-

bristle brush. The brush is particularly useful for dislodging

dirt on and around the controls and connectors. Dirt that

remains can be removed with a soft cloth dampened in a

mild detergent and water solution. Do not use abrasive

cleaners.

Two plastic light filters, one blue and one clear, are pro-

vided with the oscilloscope. Clean the light filters and the

CRT face with a soft lint-free cloth dampened with either

isopropyl alcohol or a mild detergent and water solution.

Interior

To gain access to internal portions of the instrument for

inspection and cleaning, refer to the "Removal and

Replacement Instructions" in the "Corrective Maintenance"

part of this section.

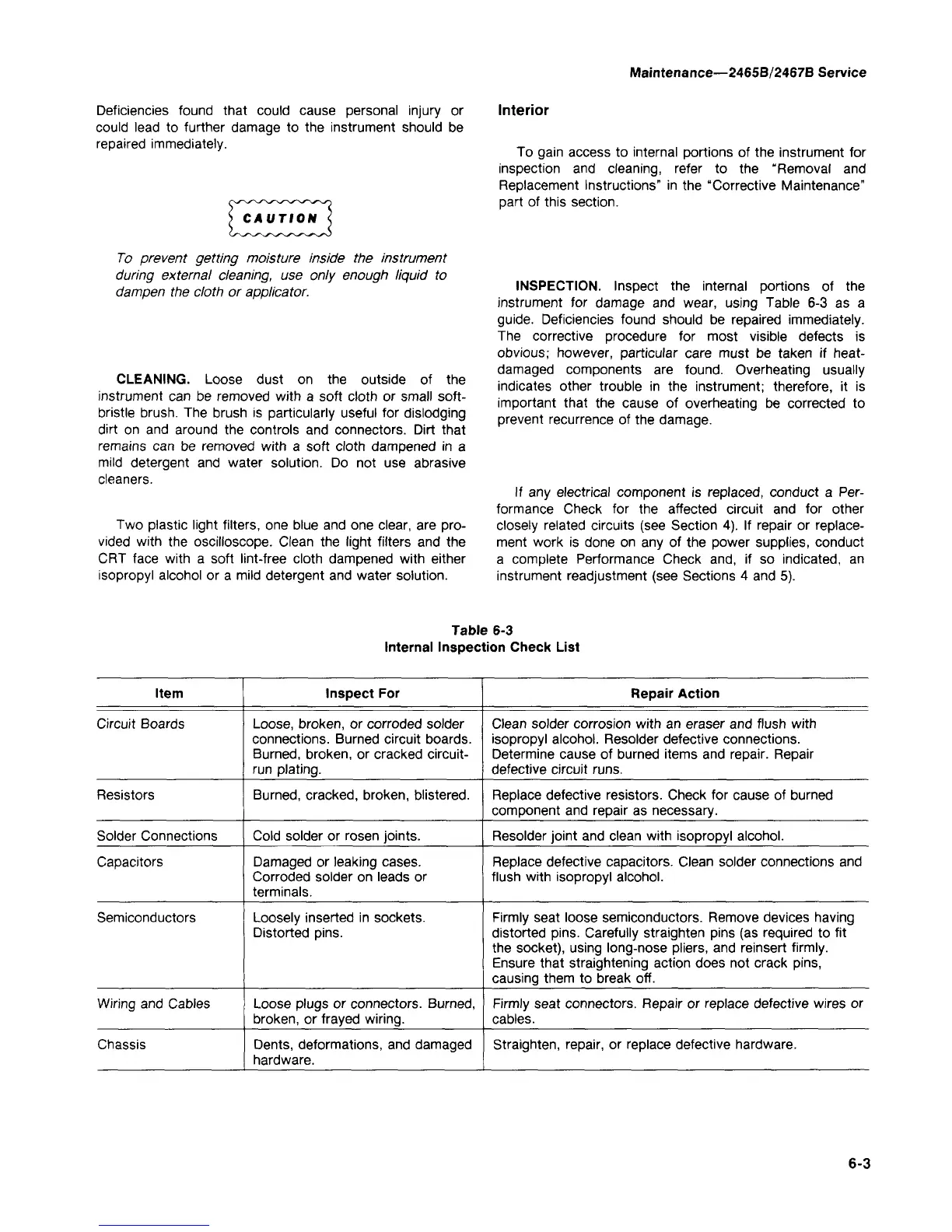

INSPECTION. Inspect the internal portions of the

instrument for damage and wear, using Table 6-3 as a

guide.

Deficiencies found should be repaired immediately.

The corrective procedure for most visible defects is

obvious; however, particular care must be taken if heat-

damaged components are found. Overheating usually

indicates other trouble in the instrument; therefore, it is

important that the cause of overheating be corrected to

prevent recurrence of the damage.

If any electrical component is replaced, conduct a Per-

formance Check for the affected circuit and for other

closely related circuits (see Section 4). If repair or replace-

ment work is done on any of the power supplies, conduct

a complete Performance Check and, if so indicated, an

instrument readjustment (see Sections 4 and 5).

Table 6-3

Internal Inspection Check List

Item

Circuit Boards

Resistors

Solder Connections

Capacitors

Semiconductors

Wiring and Cables

Chassis

Inspect For

Loose,

broken, or corroded solder

connections. Burned circuit boards.

Burned,

broken, or cracked circuit-

run plating.

Burned,

cracked, broken, blistered.

Cold solder or rosen joints.

Damaged or leaking cases.

Corroded solder on leads or

terminals.

Loosely inserted in sockets.

Distorted pins.

Loose plugs or connectors. Burned,

broken,

or frayed wiring.

Dents, deformations, and damaged

hardware.

Repair Action

Clean solder corrosion with an eraser and flush with

isopropyl alcohol. Resolder defective connections.

Determine cause of burned items and repair. Repair

defective circuit runs.

Replace defective resistors. Check for cause of burned

component and repair as necessary.

Resolder joint and clean with isopropyl alcohol.

Replace defective capacitors. Clean solder connections and

flush with isopropyl alcohol.

Firmly seat loose semiconductors. Remove devices having

distorted pins. Carefully straighten pins (as required to fit

the socket), using long-nose pliers, and reinsert firmly.

Ensure that straightening action does not crack pins,

causing them to break off.

Firmly seat connectors. Repair or replace defective wires or

cables.

Straighten,

repair, or replace defective hardware.

6-3

Loading...

Loading...