Theory of Operation—2465B/2467B Service

Inverting the Channel 2 signal for the CH 2 INVERT

feature is accomplished by biasing on different amplifiers.

The control data clocked into the internal control register

from pin 22 sets up the necessary switching.

Illumination circuitry, redrawn to show U130C through

130F as Darlington transistor pairs for the purpose of the

following description.

The Channel 2 BPO+ signal at U200 pin 11 provides

an accurate representation of the Channel 2 signal at the

rear-panel CH 2 OUT connector.

Channel 3 and Channel 4 Preamplifier

The functions provided by the Channel 3 and Channel 4

Preamplifier are similar to those provided by the Channel 1

and Channel 2 Preamplifiers. The single-ended CH 3 and

CH 4 input signals are converted to differential signals,

and vertical gain and vertical positioning are added to the

output signals. Trigger pickoff signals are generated for

both channels and are routed to the Trigger hybrid.

Channel 3 and Channel 4 gains may be either 0.1 volt

per division or 0.5 volt per division. The logic levels of

con-

trol bits applied to U300 pin 30 (GA3) and pin 31 (GA4)

from Auxiliary Control Register U140 sets the gain of the

Channel 3 and Channel 4 preamplifiers respectively. Verti-

cal positioning of the Channel 3 and Channel 4 signals on

the crt is controlled by the voltage levels applied to pin 29

(POS3) and pin 32 (POS4) from the front-panel CH 3 and

CH 4 POSITION potentiometers (via MUX U2530 and

sample-and-hold amplifiers U2430C and C2333 and

U2430D and C2332).

Dc offsets in the output signal due to any tracking

differences between the + 5-V and the -5-V supply to

U300 are reduced by the tracking regulator circuit com-

posed of U165A, Q190, and associated components.

Operational amplifier U165A and Q190 is configured so

that the output of voltage at the emitter of Q190 follows

the -5-V supply applied to R198. This tracking arrange-

ment ensures that the supply voltages are of equal magni-

tudes to minimize dc offsets in the output signals.

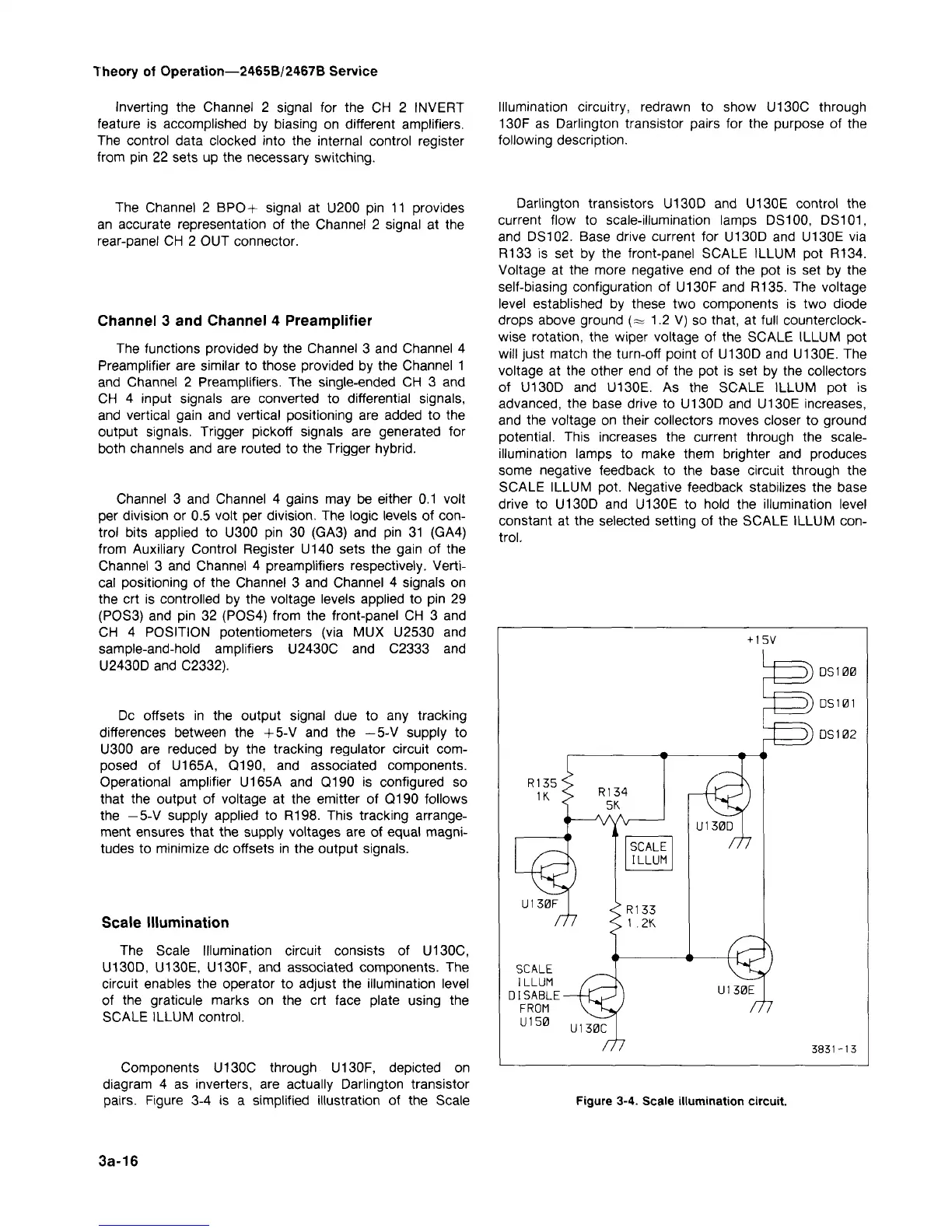

Scale Illumination

The Scale Illumination circuit consists of U130C,

U130D,

U130E, U130F, and associated components. The

circuit enables the operator to adjust the illumination level

of the graticule marks on the crt face plate using the

SCALE ILLUM control.

Components U130C through U130F, depicted on

diagram 4 as inverters, are actually Darlington transistor

pairs.

Figure 3-4 is a simplified illustration of the Scale

Darlington transistors U130D and U130E control the

current flow to scale-illumination lamps DS100,

DS101,

and DS102. Base drive current for U130D and U130E via

R133 is set by the front-panel SCALE ILLUM pot R134.

Voltage at the more negative end of the pot is set by the

self-biasing configuration of U130F and R135. The voltage

level established by these two components is two diode

drops above ground (=s 1.2 V) so that, at full counterclock-

wise rotation, the wiper voltage of the SCALE ILLUM pot

will just match the turn-off point of U130D and U130E. The

voltage at the other end of the pot is set by the collectors

of U130D and U130E. As the SCALE ILLUM pot is

advanced,

the base drive to U130D and U130E increases,

and the voltage on their collectors moves closer to ground

potential.

This increases the current through the scale-

illumination lamps to make them brighter and produces

some negative feedback to the base circuit through the

SCALE ILLUM pot. Negative feedback stabilizes the base

drive to U130D and U130E to hold the illumination level

constant at the selected setting of the SCALE ILLUM

con-

trol.

-15V

U130F

SCALE

ILLUM

DISABLE

FROM

U150

SCALE

LLUM

U130D

m

3) DSI00

D)DS101

D) DS102

U130C

m

3851-13

Figure 3-4. Scale illumination circuit.

3a-16

Loading...

Loading...