7

Unit Description

The Thermo King V250 is a truck refrigeration system that

is designed for low and medium temperature applications

on medium-sized trucks. There are two basic models:

• Model 10: Cool and defrost on engine-driven compres-

sor operation.

• Model 20: Cool and defrost on both truck engine-

driven and electric standby compressor operation.

The system consist of three separate assemblies: the con-

denser, the evaporator, and the compressor.

The condenser has a unique design that allows it to be

mounted horizontally or vertically, on the roof or on the

front of the truck box.

The evaporator is mounted inside the truck box. Funnel and

thin-line evaporators are available. The funnel evaporator

mounts on the ceiling or the front wall. The thin-line evapo-

rator mounts on the front wall.

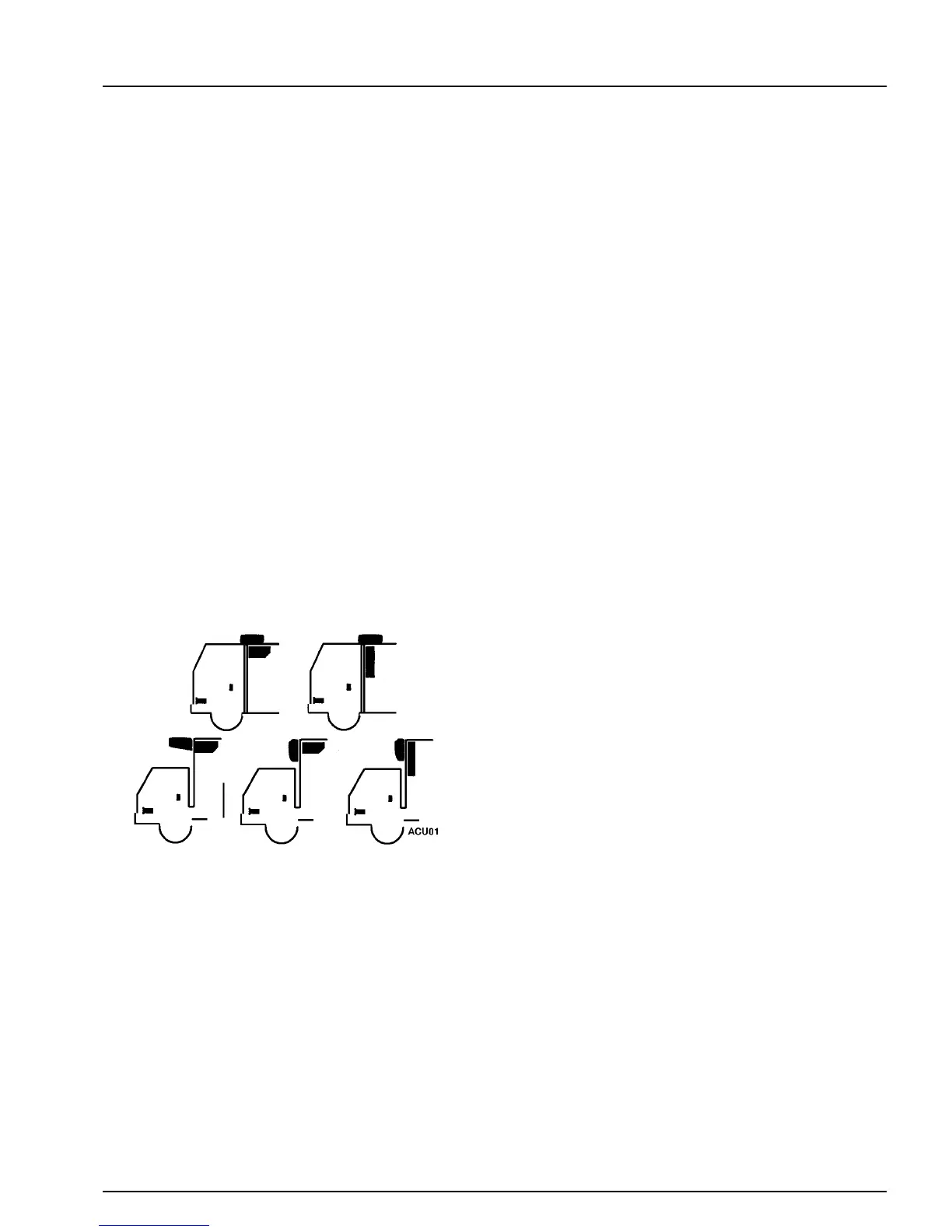

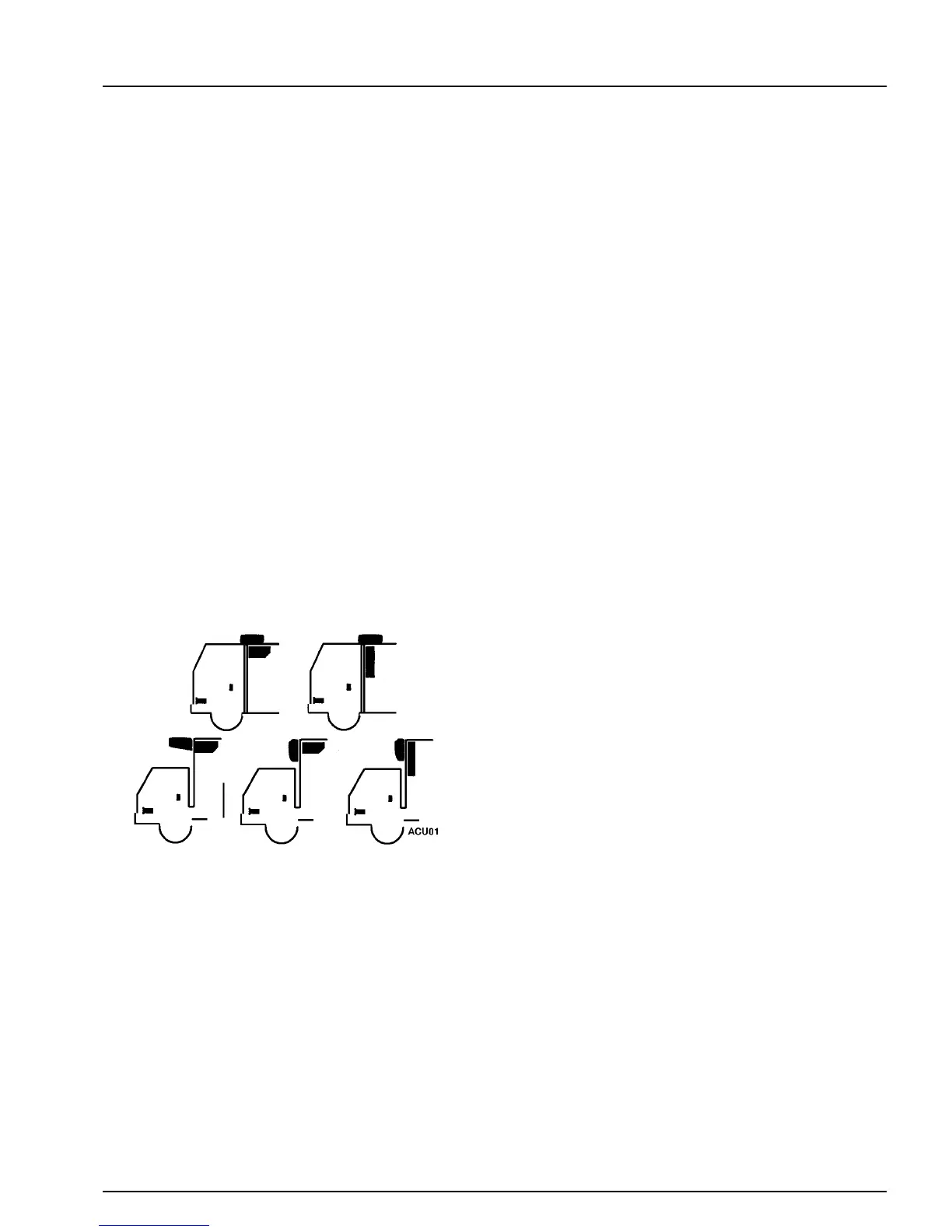

Condenser and Evaporator Configurations

The compressor is mounted on and driven by the truck

engine. Refrigeration hoses or lines are used to connect the

condenser, the evaporator and the compressor. Model 20

units have another compressor and an electric motor

mounted in the condenser section for electric standby

operation.

The electric standby compressor is connected in parallel

with the engine-driven compressor. The engine compressor

is driven by a belt from the engine. The standby compressor

is driven by a belt from the electric motor. Both compres-

sors use the same refrigeration system circuit. Check valves

isolate one compressor from the other during operation.

Compressor operation is controlled by the thermostat,

which energizes the compressor clutch during engine opera-

tion or starts the electric motor and energizes the compres-

sor clutch on electric standby operation. The refrigeration

system is protected by a high pressure cutout switch and a

low pressure cutout switch.

The control circuits operate on 12 volts dc supplied by the

truck battery for over-the-road operation. On standby oper-

ation, the power is rectified from an ac transformer.

The cab control box is mounted in the truck cab. It contains

the On-Off key, Manual Defrost key, thermometer, thermo-

stat, and indicator lights.

Liquid Injection System

If the discharge gas leaving the engine driven compressor

reaches a temperature of 230 ± 5 F (110 ± 3 C), the liquid

injection switch closes, providing voltage to the liquid injec-

tion solenoid. The solenoid opens a valve, allowing liquid

refrigerant to flow from the liquid line near the receiver out-

let valve to the metering orifice attached to the suction fit-

ting at the compressor. As the refrigerant passes through the

metering orifice it expands and evaporates, cooling the suc-

tion gas entering the compressor. This cooling effect is

transferred to the discharge gas leaving the compressor from

the adjacent cavity in the compressor head. When the dis-

charge gas is cooled to 200 ± 5 F (93 ± 3 C), the liquid injec-

tion switch opens, the liquid injection solenoid valve closes

and refrigerant no longer flows through the liquid injection

system.

Loading...

Loading...