Refrigeration Maintenance (Rev 1/99)

55

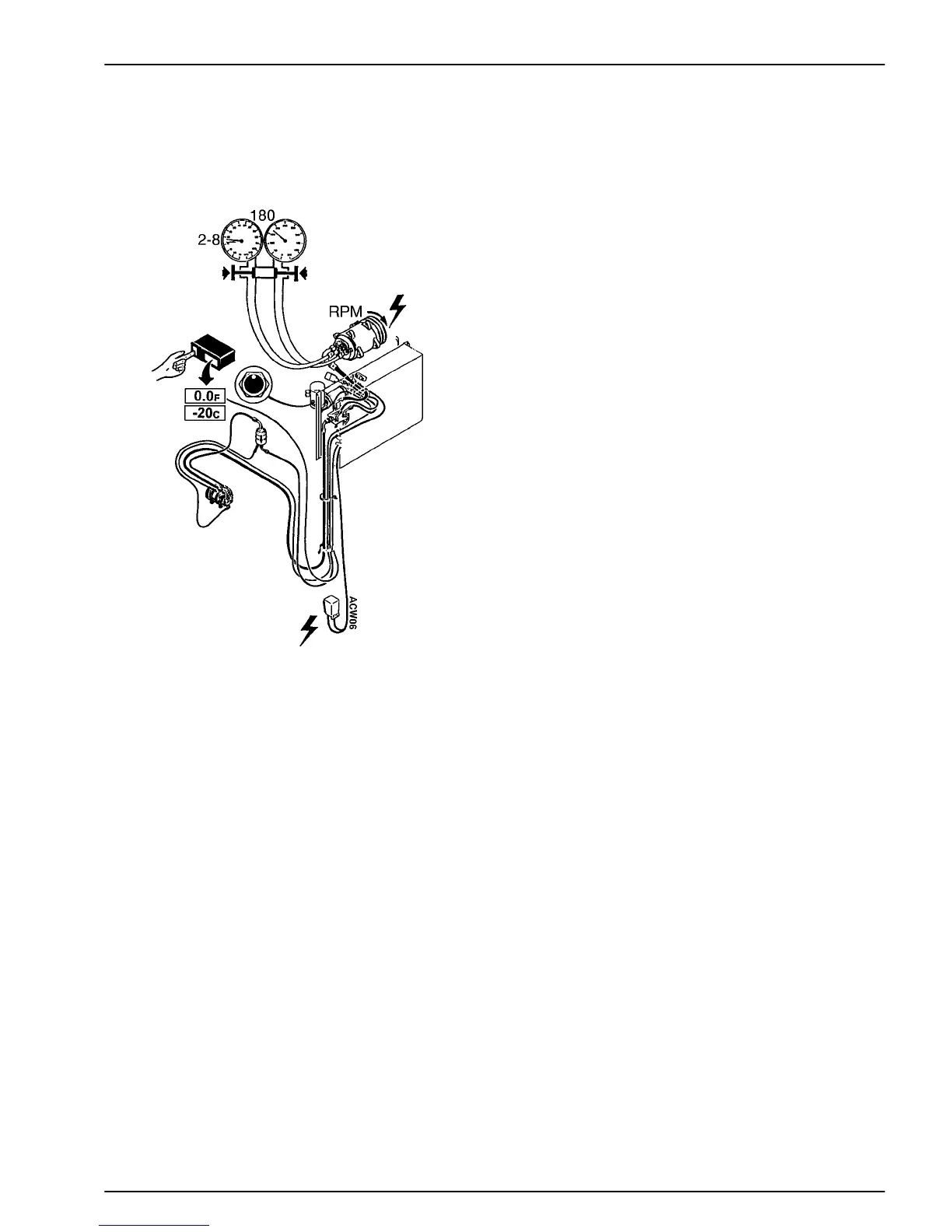

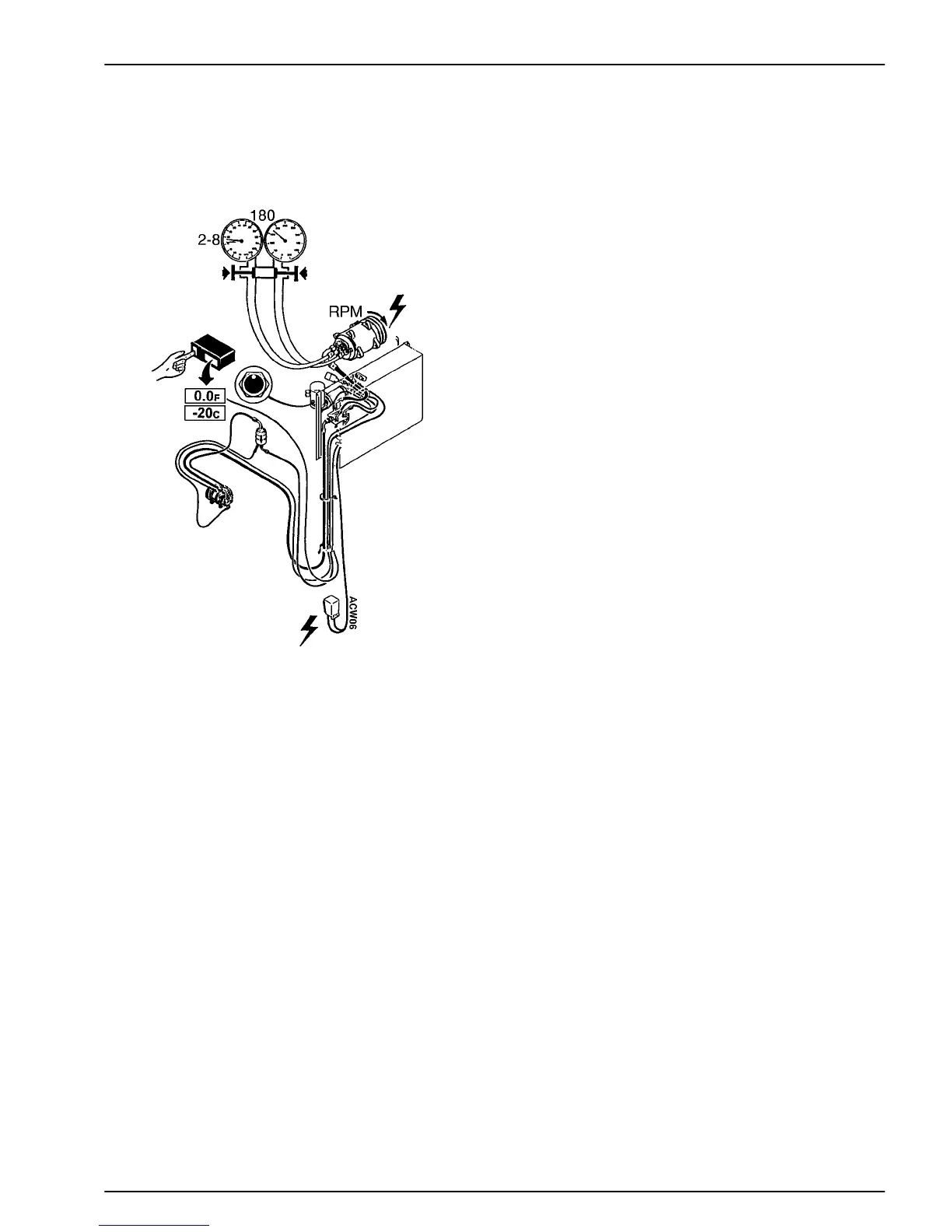

Run On Electric Operation

c. Turn the unit OFF and disconnect the electric

power supply. Start the truck and run the unit in

cool on engine operation for a minimum of 15

minutes.

17. Check the receiver tank sight glass with the unit running

in cool, the box temperature at 0 F (-20 C), and a head

pressure of at least 180 psi (1241 kPa) for R-134a sys-

tems and 275 psi (1896 kPa) for R-404A systems. The

ball should be at the top of the sight glass.

If not, open the valve on the refrigerant drum to deliv-

ery liquid and open the low side valve on the gauge

manifold. Add refrigerant liquid until the ball in the

receiver tank sight glass reaches the top of the sight

glass, then close the valve on the refrigerant drum and

close the low side valve on the gauge manifold.

18. Stop the unit, shut OFF the truck engine and remove the

gauge manifold set.

19. The above conditions MUST be established each time

the refrigerant level is checked or if refrigerant needs to

be added for any reason.

NOTE: To prevent oil migration from one compressor to

another, and for proper oil return when a compressor is

operating, operate a compressor for a minimum of 15 min-

utes. Do not operate the compressor for shorter intervals.

Checking the Refrigerant Charge

If the unit has an insufficient charge of refrigerant, the evap-

orator will be “starved” and the box temperature will rise

even though the unit is operating. Also, an insufficient

charge does not circulate enough oil to properly lubricate

the compressor. The charge may be determined by inspec-

tion of the refrigerant through the receiver tank sight glass

with the following conditions established:

Testing the Refrigerant Charge with an Empty Box

1. Place a test box over the evaporator.

2. Install a gauge manifold set.

3. Run the unit in cool on engine operation until the ther-

mometer reads 0 F (-18 C). By allowing the box to leak

a small amount, you will be able to maintain 0 F (-18 C).

4. The discharge or head pressure gauge should be at least

180 psi (1241 kPa) on the gauge manifold for R-134a

systems and 275 psi (1896 kPa) for R-404A systems.

If the pressure is below this, it can be raised by cover-

ing a portion of the condenser grille with a piece of

cardboard.

5. Under these conditions the ball should be at the top of

the sight glass to indicate a full charge.

Loading...

Loading...