75

Structural Maintenance

UNIT INSPECTION

Inspect the unit during the pre-trip inspection and during

scheduled maintenance inspections for loose or broken

wires or hardware, compressor oil leaks, or other physical

damage which might affect the unit performance and

require the repair or replacement of parts.

EVAPORATOR COIL

Clean the evaporator coil during scheduled maintenance

inspection by blowing compressed air down through the

coil out into the box (direction opposite the normal air

flow). Inspect the coil and fins for damage and repair if

necessary (requires removing the evaporator fan and front

cover).

CAUTION: Air pressure should not be high enough

to damage the coil fins.

CONDENSER COIL

Clean the condenser coil during scheduled maintenance

inspections by blowing compressed air from the back side

of the coil out toward the front of the unit (the direction

opposite normal air flow). Inspect the coil and fins for dam-

age and repair if necessary.

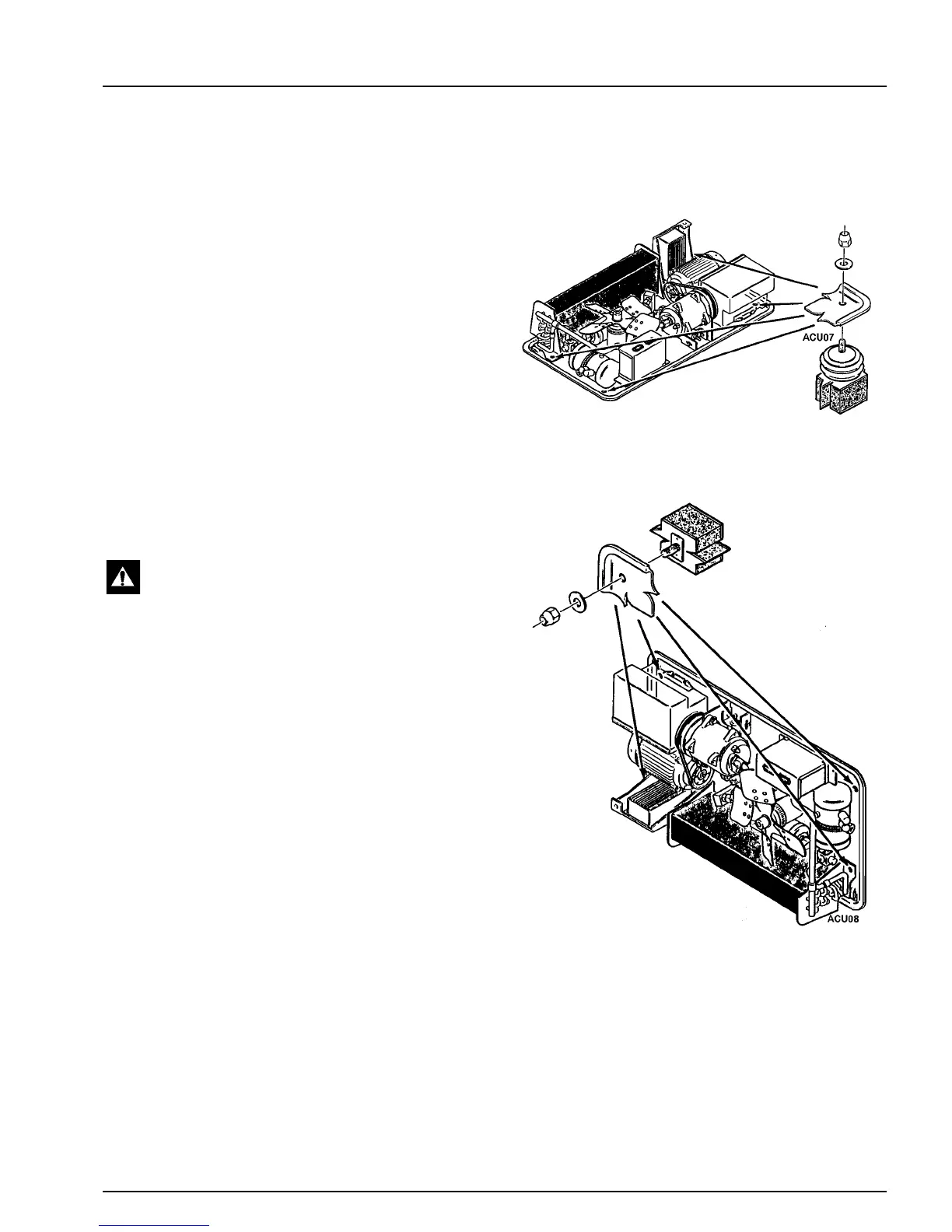

CONDENSER FAN LOCATION

Mount the condenser fan so the hub is flush with the end of

the shaft.

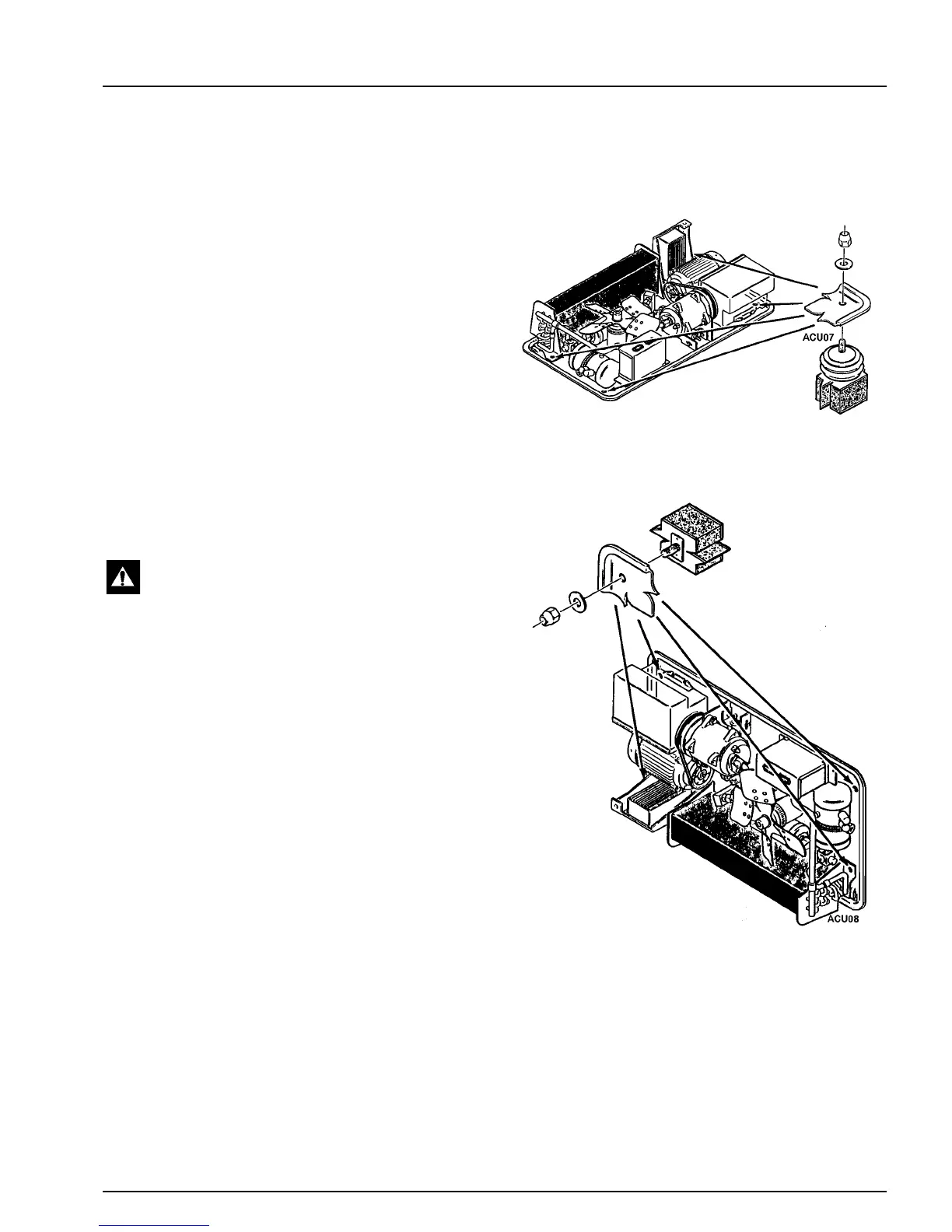

UNIT MOUNTING BOLTS

Periodically check and torque the unit mounting bolts to 60

ft-lb (81 N•m).

Roofmount Unit

Nosemount Unit

Loading...

Loading...