DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Varythetirepressureforthefrontwheels,depending

uponyourturfconditions,fromaminimumof55kPa

(8psi)toamaximumof83kPa(2psi).

Varythetirepressurefortherearwheelfroma

minimumof55kPa(8psi)toamaximumof103kPa

(15psi).

CheckingtheTorqueofthe

WheelNuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every200hours

WARNING

Failuretomaintainpropertorqueofthewheel

nutscouldresultinpersonalinjury.

Torquethewheelnutstothespeciedtorque

atthespeciedintervals.

Wheelnuttorquespecication:95to122N∙m(70

to90ft-lb)

Note:Toensureevendistribution,torquethewheel

nutsinaXpattern.

AdjustingtheTransmission

forNeutral

Ifthemachinecreepswhenthetractioncontrolpedal

isintheNEUTRALposition,adjusttheneutral-return

mechanism.

1.Blockupundertheframesothatoneofthefront

wheelsisoffoftheoor.

Note:Ifthemachineisequippedwitha3-Wheel

DriveKit,raiseandblocktherearwheel.

2.Starttheengine,movethethrottletotheSLOW

position,andensurethatthefrontwheelthatis

offoftheoorisnotrotating.

3.Ifthewheelisrotating,shutofftheengineand

proceedasfollows:

A.Loosenbothjamnutssecuringthe

traction-controlcabletothebulkheadonthe

hydrostat(Figure40).Ensurethatthejam

nutsareloosenedequallyandsufciently

toallowadjustment.

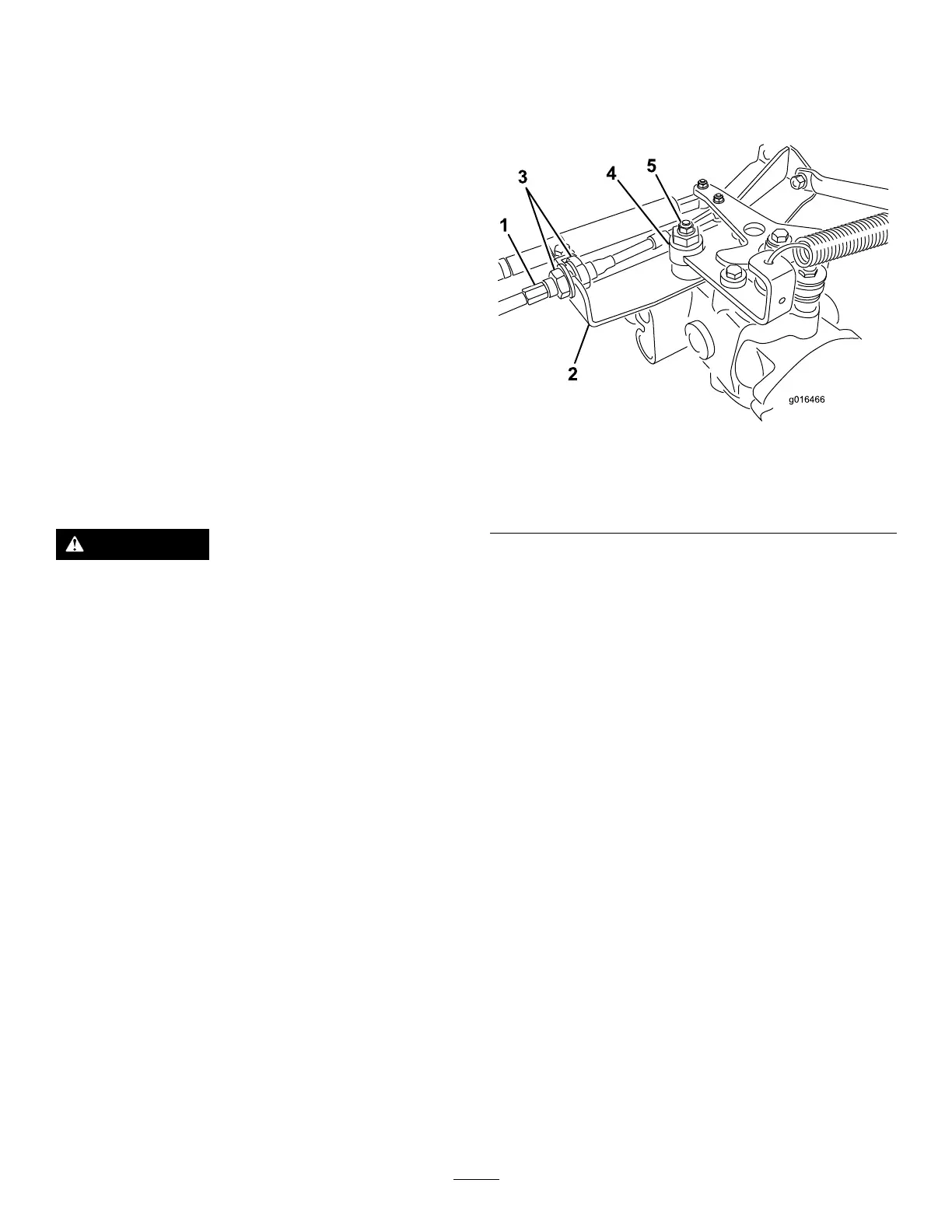

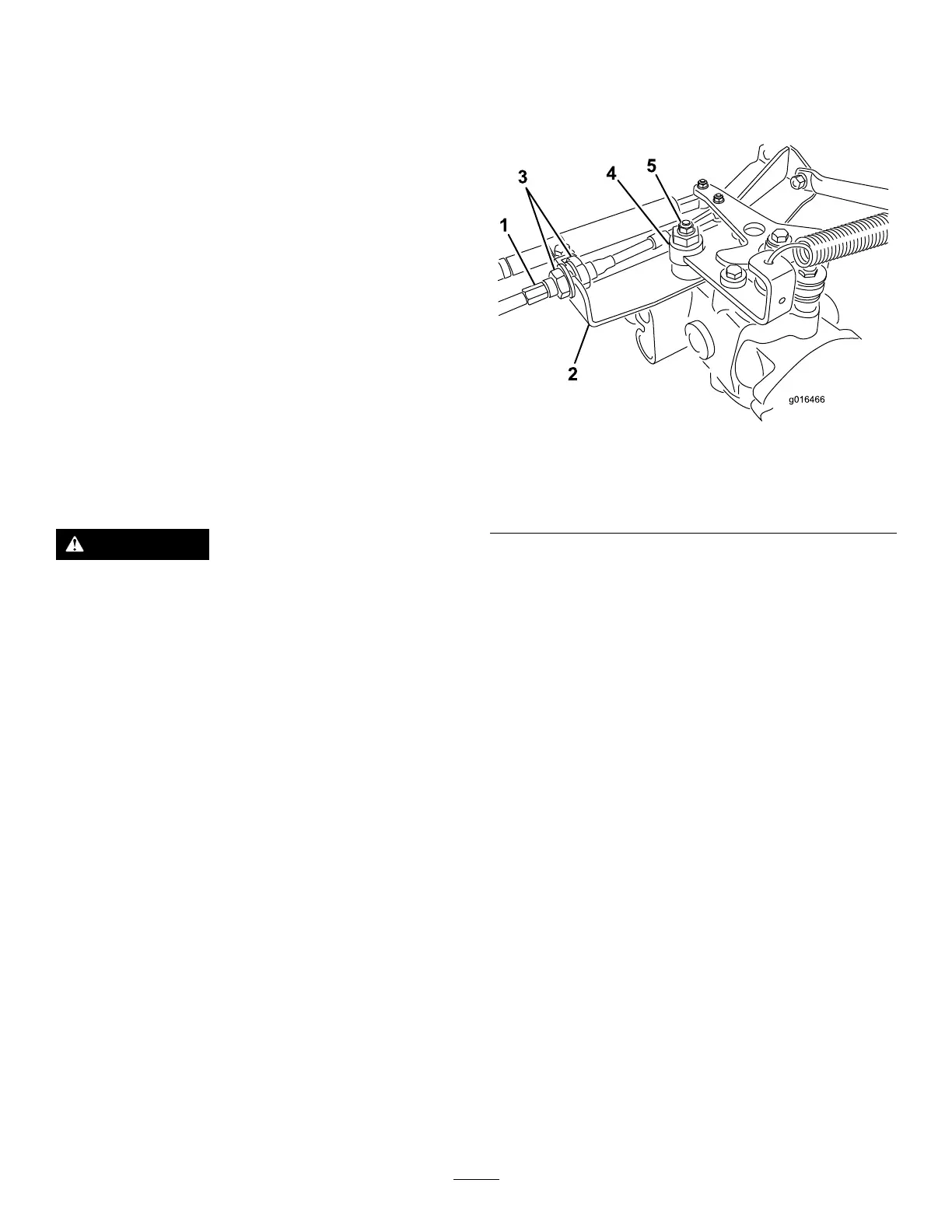

g016466

Figure40

1.Tractioncable4.Eccentric

2.Bulkhead5.Locknut

3.Jamnuts

Note:Loosenthenutsecuringthe

eccentrictothetopofthehydrostat(Figure

40).

B.Movethefunctional-controllevertothe

NEUTRALpositionandthethrottleleverto

theSLOWposition.

C.Starttheengine.

D.Rotatetheeccentricuntilcreepdoesnot

occurineitherdirection.

E.Whenthewheelstopsrotating,tightenthe

nutlockingtheeccentricandtheadjustment

(Figure40).

F.Verifytheadjustmentwiththethrottlelever

intheSLOWandFASTposition.

G.Fromeachsideofthebulkhead,tightenthe

locknutsevenly,securingthetractioncable

tothebulkhead(Figure40).Donottwist

thecable.

Note:Ifcabletensionexistswhenthe

functional-controlleverisintheNEUTRAL

position,themachinemaycreepwhenyou

movethelevertotheMOWorTRANSPORT

position.

39

Loading...

Loading...