BeltMaintenance

AdjustingtheAlternator

Belt

ServiceInterval:Aftertherst8hours

Ensurethatthebeltisproperlytensionedtoensure

properoperationofthemachineandprevent

unnecessarywear.

1.Parkthemachineonalevelsurface,shutoffthe

engine,engagetheparkingbrake,removethe

key,andwaitforallmovingpartstostop.

2.Applymoderatethumbpressuretothebelt

betweenthepulleys(10kgor22lb).Thebelt

shoulddeect7to9mm(0.28to0.35inch).If

not,completethefollowingproceduretoadjust

thebelttension:

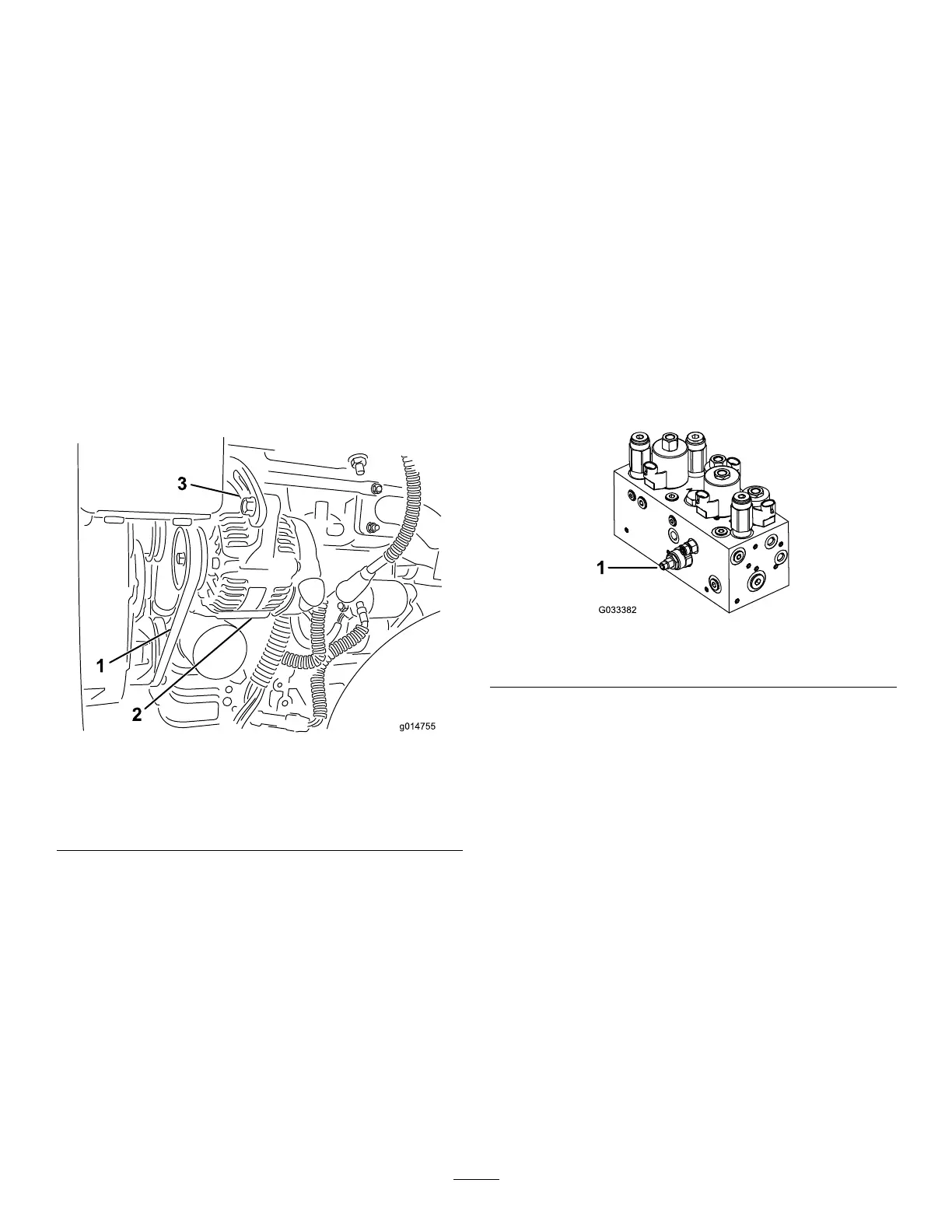

g014755

Figure46

1.Alternatorbelt—applypressurehere

2.Alternator

3.Adjustingstrap

A.Loosentheboltssecuringthealternatorto

theengineandadjustingstrap.

B.Inspectthebeltforwearordamageand

replaceifitisworn.

C.Usingaleverplacedbetweenthealternator

andtheengineblock,pullthealternatorout

toobtainthecorrectbelttensionandtighten

thebolts.

ControlsSystem

Maintenance

AdjustingtheCuttingUnit

Lift/Drop

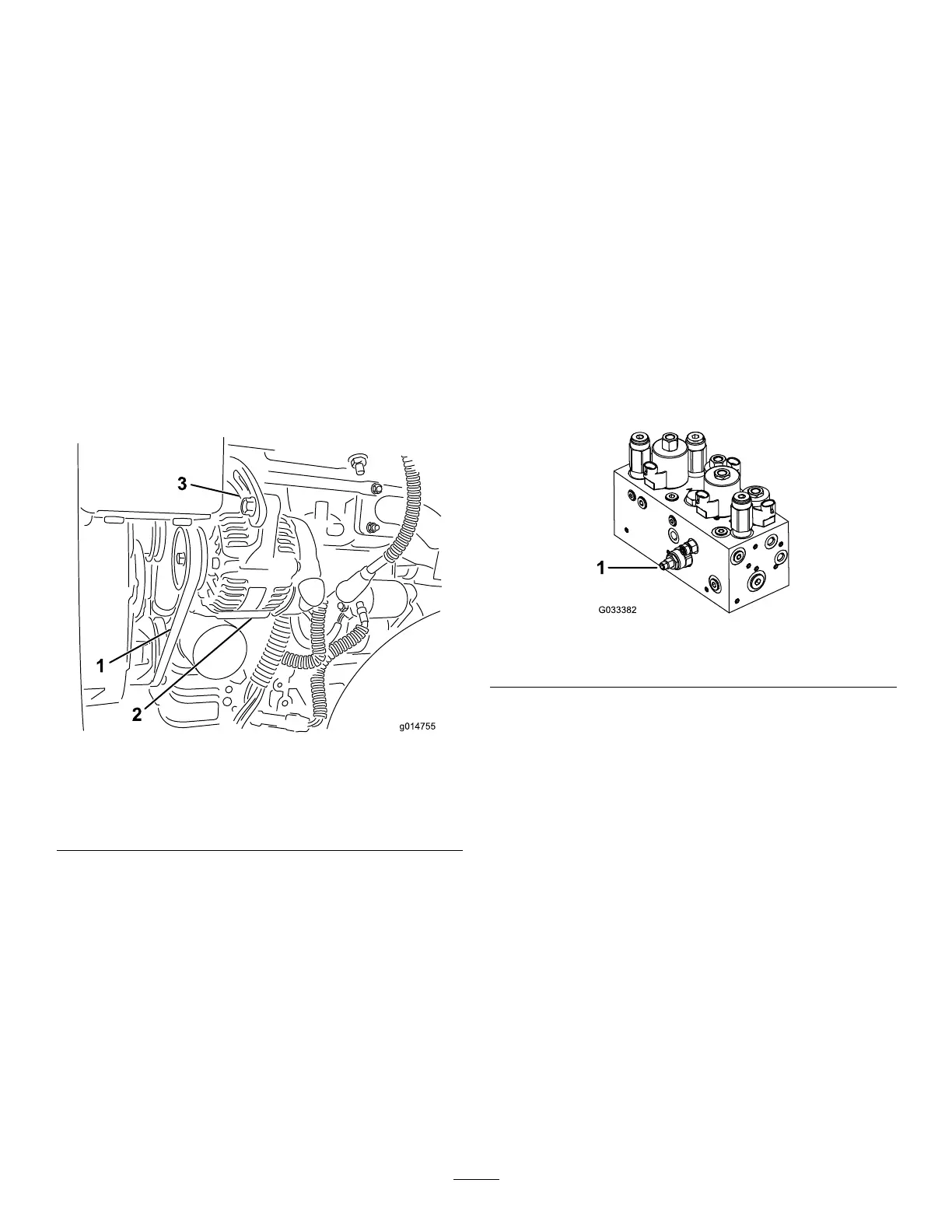

Thecuttingunitlift/dropcircuitcomeswitha

ow-controlvalve(Figure47).Thisvalveispreset

atthefactoryatapproximately3turnsopen,butyou

mayneedtoadjustittocompensatefordifferencesin

hydraulicuidtemperatures,mowingspeeds,etc.

Note:Allowthehydraulicuidtoreachfulloperating

temperaturebeforeadjustingtheow-controlvalve.

1.Raisetheseatandlocatetheow-controlvalve

forthecenter-pullframe(Figure47),whichis

locatedonthesideofthehydraulicmanifold.

g033382

Figure47

1.Flow-controlvalve

2.Loosenthejamnutontheadjustingknobonthe

owcontrolvalve.

3.Rotatetheknobcounterclockwiseifthecenter

cuttingunitisdroppingtoolateorclockwiseif

thecentercuttingunitisdroppingtooearly.You

shouldnotneedtorotateitmorethan1/32to

1/16ofaturn.

4.Testtheadjustmentandrepeatstep3as

needed;whennished,tightenthejamnut.

43

Loading...

Loading...