CheckingtheHydraulic-Fluid

Level

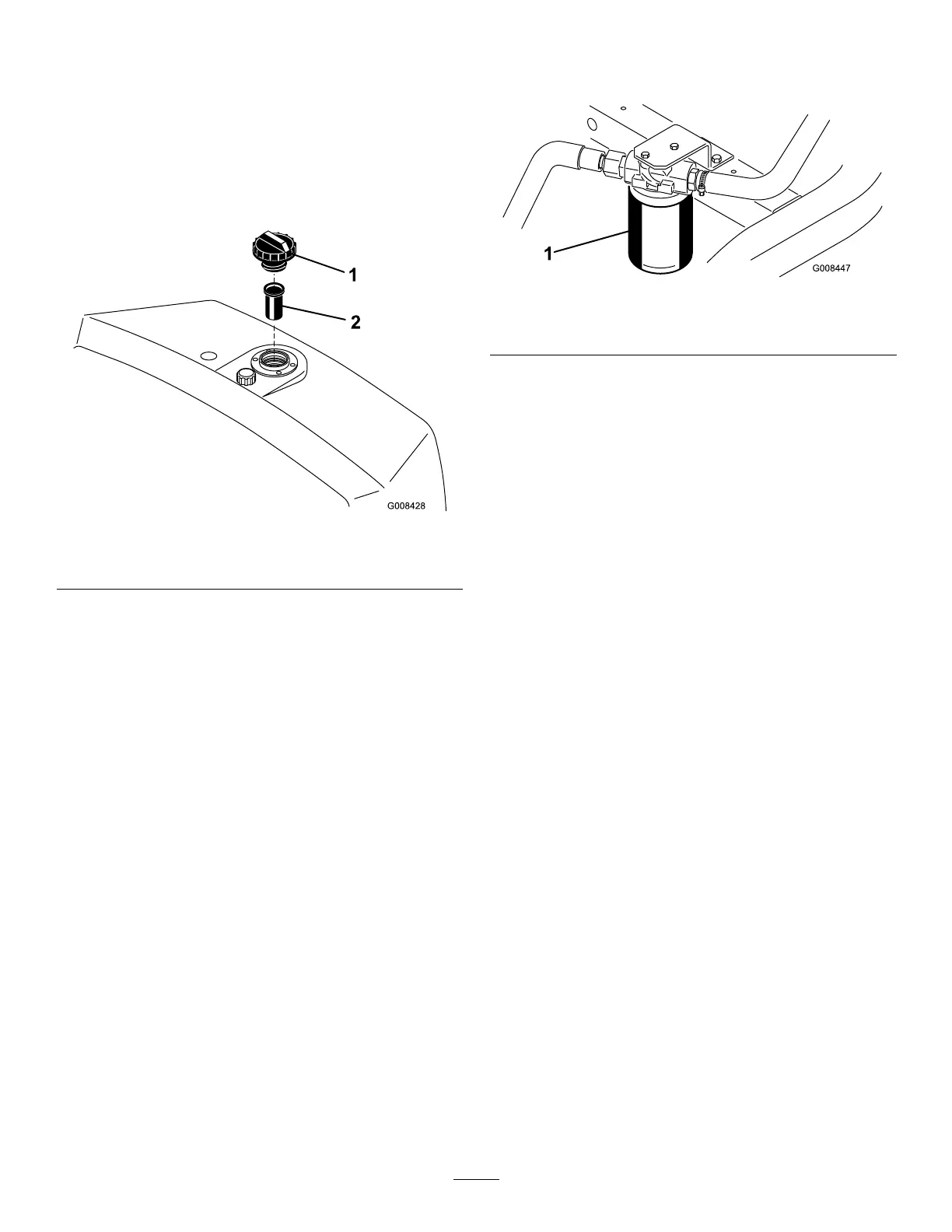

1.Parkthemachineonalevelsurface.Ensure

thatthemachinehascooleddownsotheuid

iscold.

2.Removethecapfromthereservoirandcheck

theuidlevel.Theuidshouldbeuptothe

bottomofthescreeninthellerneck(Figure48).

g008428

Figure48

1.Hydraulicreservoir

2.Screen

3.Iftheuidlevelislow,slowlyllthereservoir

withtheappropriatehydraulicuiduntilthe

levelreachesthebottomofthescreen.Donot

overll.

Important:Topreventsystem

contamination,cleanthetopofthe

hydraulicuidcontainersbeforepuncturing.

Ensurethepourspoutandfunnelareclean.

4.Installthereservoircap.Wipeupanyuidthat

mayhavespilled.

Important:Checklevelofhydraulicuid

beforeengineisrststartedanddaily

thereafter.

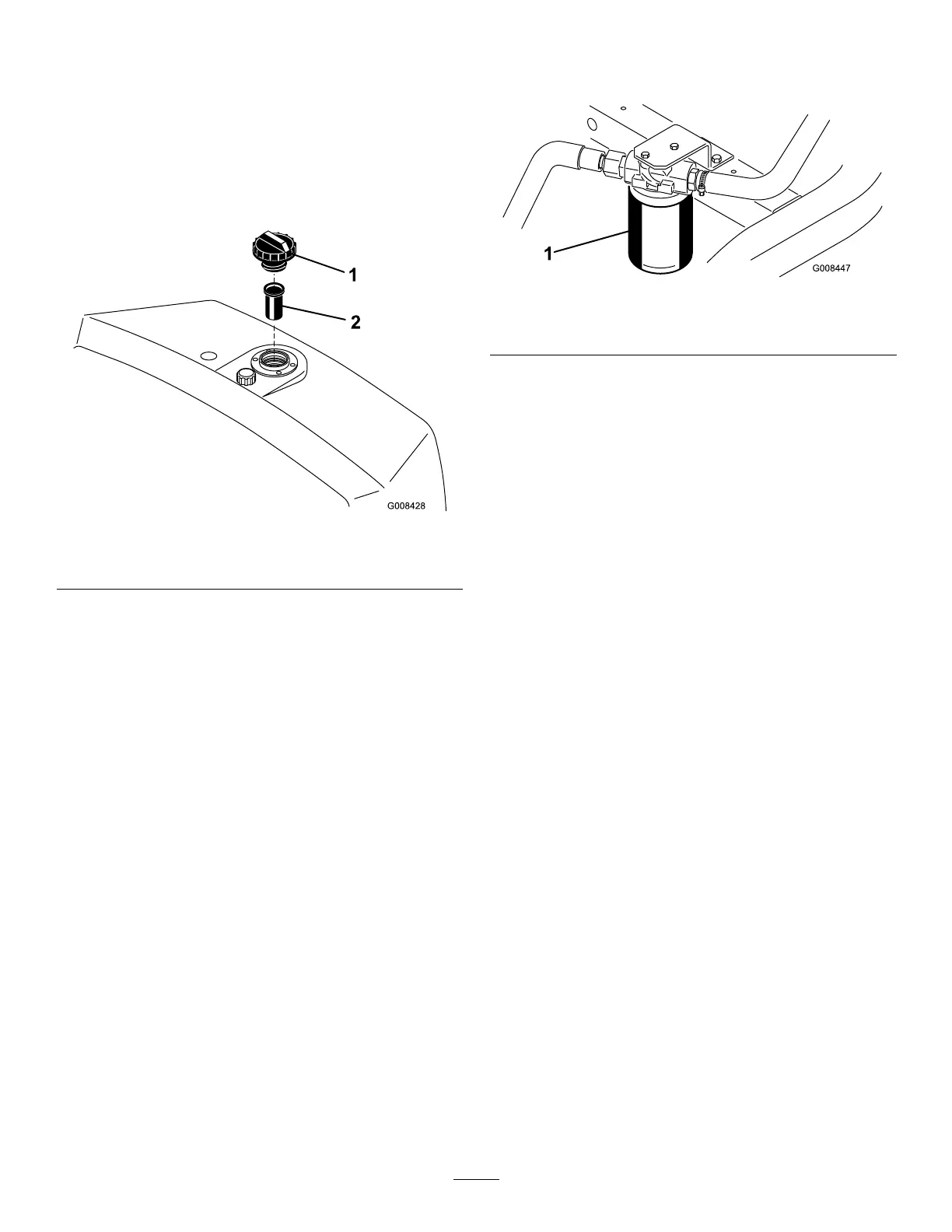

ChangingtheHydraulicFluidand

Filter

ServiceInterval:Aftertherst50hours

Every800hours

HydraulicFluidCapacity:25.7L(6.8USgallons)

Iftheuidbecomescontaminated,haveyour

authorizedTorodistributorushthesystem.

Contaminateduidlooksmilkyorblackwhen

comparedtocleanuid.

1.Cleantheareaaroundtheltermountingarea

(Figure49).Placeadrainpanunderthelter

andremovethelter.

g008447

Figure49

1.Hydraulic-uidlter

Note:Ifyouwillnotbedrainingtheuid,

disconnectandplugthehydrauliclinegoingto

thelter.

2.Fillthereplacementlterwiththeappropriate

hydraulicuid,lubricatethesealinggasket,and

handturnituntilthegasketcontactsthelter

head.Thentightenit3/4turnfurther.

3.Fillthehydraulicreservoirwithhydraulicuid;

refertoHydraulicFluidSpecications(page44)

andCheckingtheHydraulic-FluidLevel(page

45).

4.Startthemachineandrunitatidlefor3to5

minutestocirculatetheuidandremoveanyair

trappedinthesystem.Shutofftheengineand

checktheuidlevel.

5.Disposeoftheuidandlterproperly.

CheckingtheHydraulic

LinesandHoses

Checkthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

45

Loading...

Loading...