17.Rotatethedrillspindlecounterclockwisemoving

rearwardslowlyuntilthespindlefullyseparatesfrom

thepipe.

18.Retractthepipegripperarms.

19.Rotatethepipecamtothedesiredrow .

Note:Filltheoutsiderowsrst.

20.Releasethepipegripperandraisethepipeintothe

holderrow.

21.Raisethepipeintothepipebasketwiththepipe

elevators.

22.Rotatethepipegripperpastthethirdrowofpipes.

Important:Ensurethatyoufullyretractthe

pipegripperandrotateitallthewayoutorthe

carriagemaycollidewiththegripper,damaging

themachine.

23.Movethedrillspindledowntheframeunderthe

thread-joint-compoundapplicator,andspraythe

spindlewiththreadjointcompound.

24.Rotatethedrillspindleclockwiseandmovethecarriage

slowlyforwardtoinsertthespindleintothefemaleend

ofthepipesecuredinthelowerwrench.

Note:Tightenthejointuntilyoureachnomorethan

2,304N-m(1,700ft-lb).

25.Releasethewrenchandcontinuereaming/retraction

asneeded.

RemovingtheLastPipeandtheReamer

Important:Donotpullthedrillheadintothepipe

guideoryoumaydamagethemachineorthedrillhead.

1.Usingtheexit-side-lockouttransmitter,enabletheexit

sidelockout.

2.Afterthereamerhasclearedtheground,ifyouhave

notalreadydoneso,disconnecttheproductbeing

installedfromthereamer.

3.Connectthedrillinguidpumptoasourceofclean

water.

4.Turnthepumpontoushcleanwaterthroughthe

pump,spindle,andreameruntilthewaterrunsclear.

5.Removeandstorethelastpipe;refertoRemovingDrill

Pipes(page53).

6.Leavetheleadbarclampedinthelowerwrench,butdo

notconnectthedrillspindletotheleadbar.

7.Removethereamerfromtheendoftheleadbaras

directedbythereamermanufacturer.

8.Releasethelowerwrenchandpulltheleadbaroutof

thepipeguide.

FinishingtheJob

Completethefollowingaftereachdayofuse:

•Connectthehandsprayguntothepumpandcleanthe

machinewithcleanwater;refertoCleaningwiththe

Spray-HoseAttachment(page88).

•Addgreasetothegreasettings;refertoGreasingthe

Machine(page60).

•Iftheairtemperatureisbelowfreezingorwillbebefore

thenextuse,refertoPreparingtheDrilling-FluidSystem

forColdWeather(page87).

•Installthecontrolscovers;refertoOperator-Controls

Covers(page21).

•Flushthedrillinguidoutofthedrilling-uidpumpwith

waterorantifreeze.

Note:Thedrilling-uidpumpmaybedamagedifthe

drilling-uiddriesupinthepump.

UsingtheTJCApplicator

AdjustingtheApplicatorNozzle

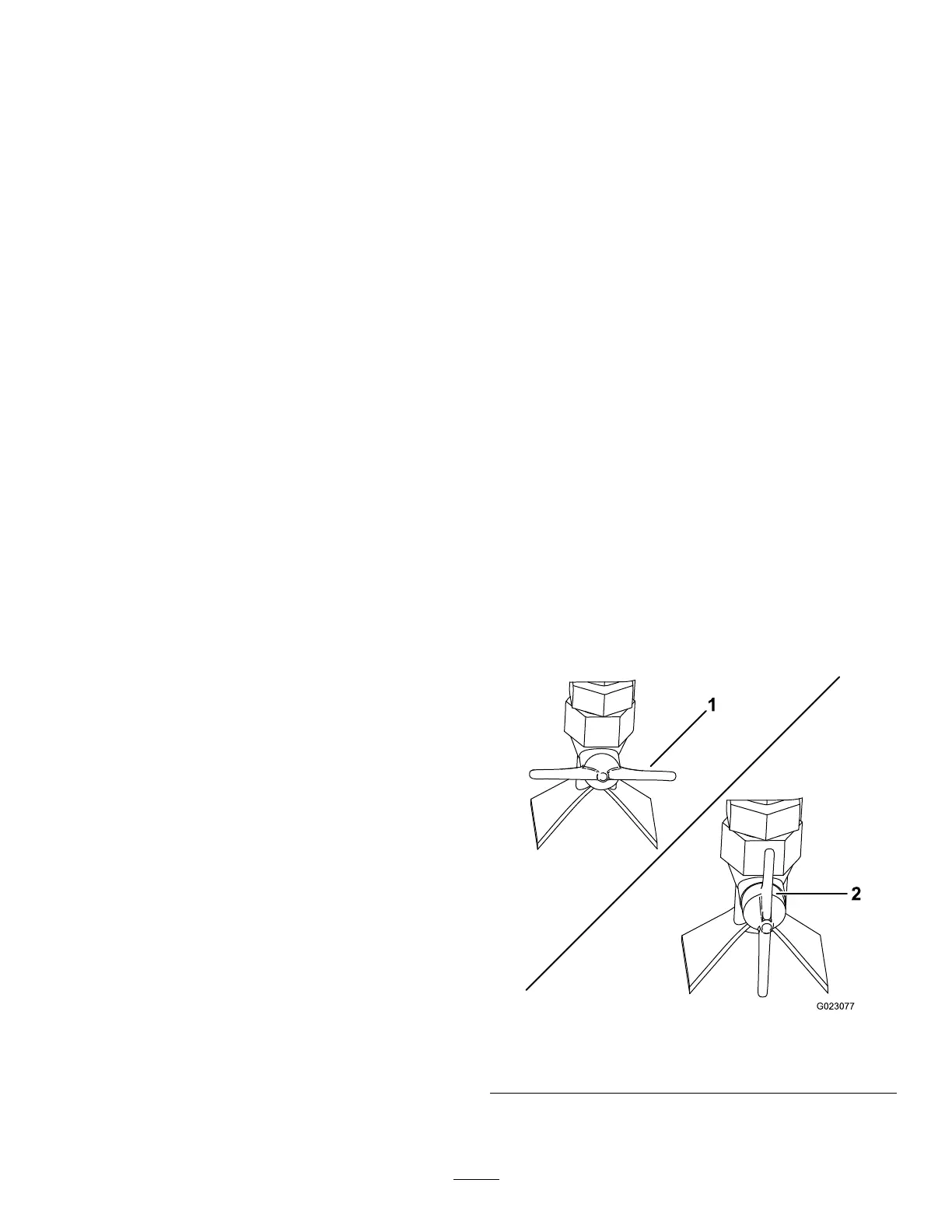

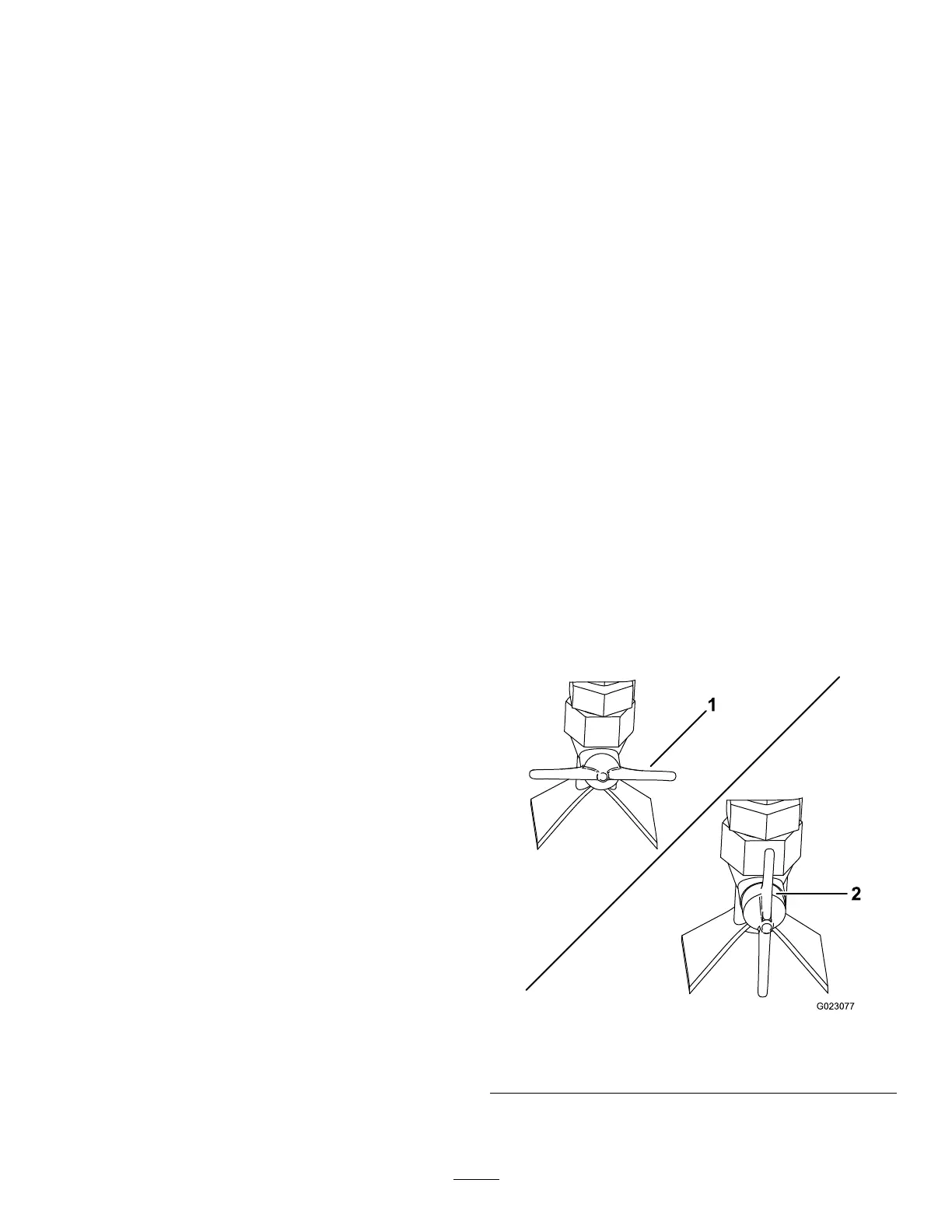

Youcanadjusttheapplicatornozzletospraythread-joint

compound(TJC)eitherinafan-shapedsprayorasastream.

•Forfan-shapedspray—turnthesprayvalveontheside

ofthenozzlehorizontal(Figure54).

•Forastream—turnthesprayvalveonthesideofthe

nozzlevertical(Figure54).

Figure54

1.Sprayvalve—fan-shaped

spray(horizontal)

2.Sprayvalve—stream

(vertical)

54

Loading...

Loading...