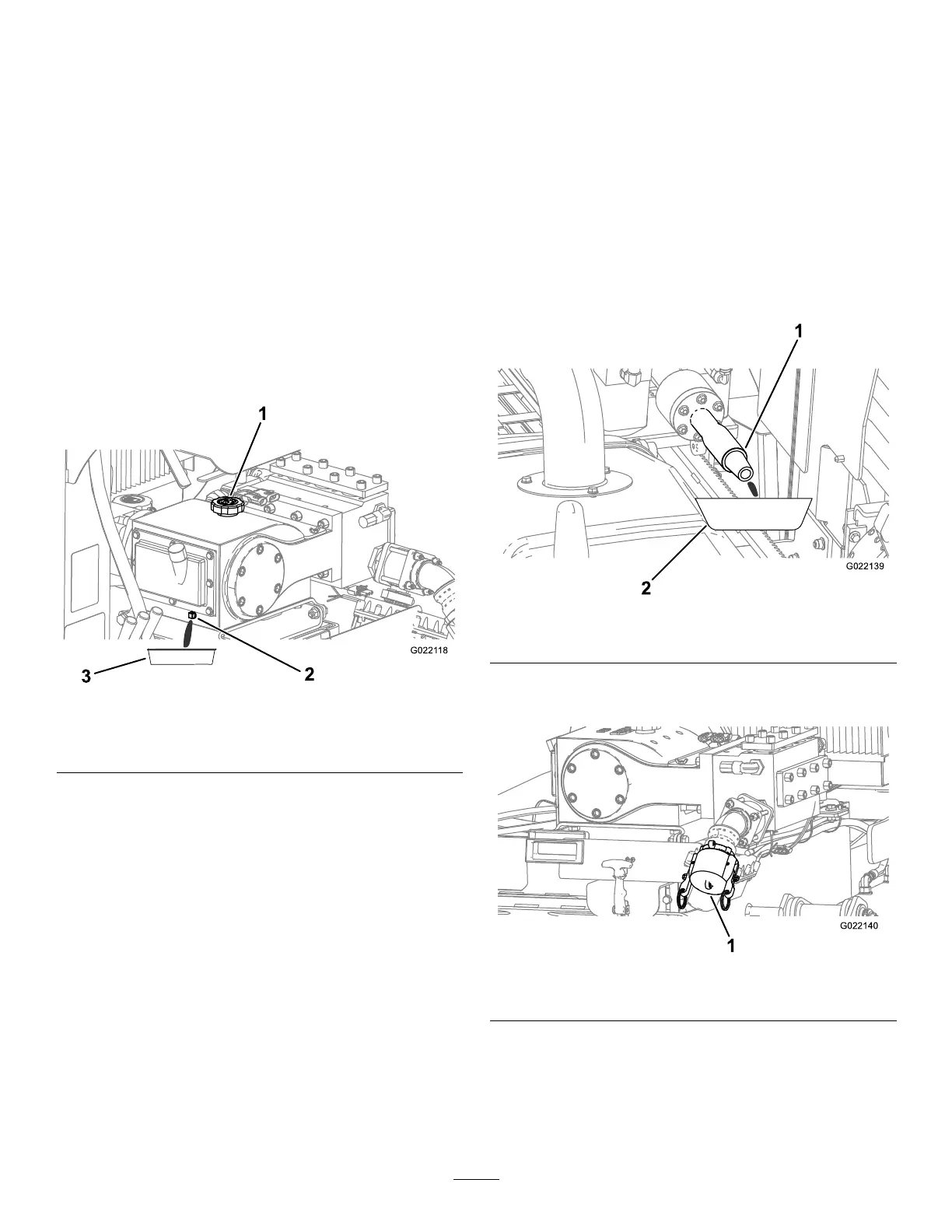

4.Ensurethattheoilisattheoil-lllineasshownin

Figure111.

Note:Iftheoilisbelowtheoil-llline,refertostep

8ofChangingtheDrilling-FluidPumpOil(page87)

andaddthenecessaryamountofoil.

ChangingtheDrilling-FluidPumpOil

ServiceInterval:Every500hours—Changethedrilling-uid

pumpoil.

1.Parkthemachineonalevelsurface,stoptheengine,

andremovetheignitionkey.

2.Opentherearhood.

3.Allowtheenginetocool.

4.Removethedrainplugandplaceadrainpanunderthe

drain-plughole(Figure112).

Figure112

1.Oil-llercap

3.Drainpan

2.Drainplug

5.Cleanthethreadsonthedrainplugandapply3layers

ofPTFEsealingtape.

6.Allowalloftheoiltodrainfromdrainplugintothe

oilpan(Figure112).

7.Installthedrainplug.

8.Removetheoil-llercap(Figure112)andadd

approximately1.9L(2qt)ofoil,oruntiltheoilreaches

theoil-lllineonthedipstickasshowninFigure111.

PreparingtheDrilling-Fluid

SystemforColdWeather

Preparethemachineasfollowsafterdrillingifthetemperature

willbebelow0°C(32°F).

1.Parkthemachineonalevelsurface,stoptheengine,

andremovetheignitionkey.

2.Preparethemachinetocirculatetheantifreezeas

follows:

A.Opentherearhood.

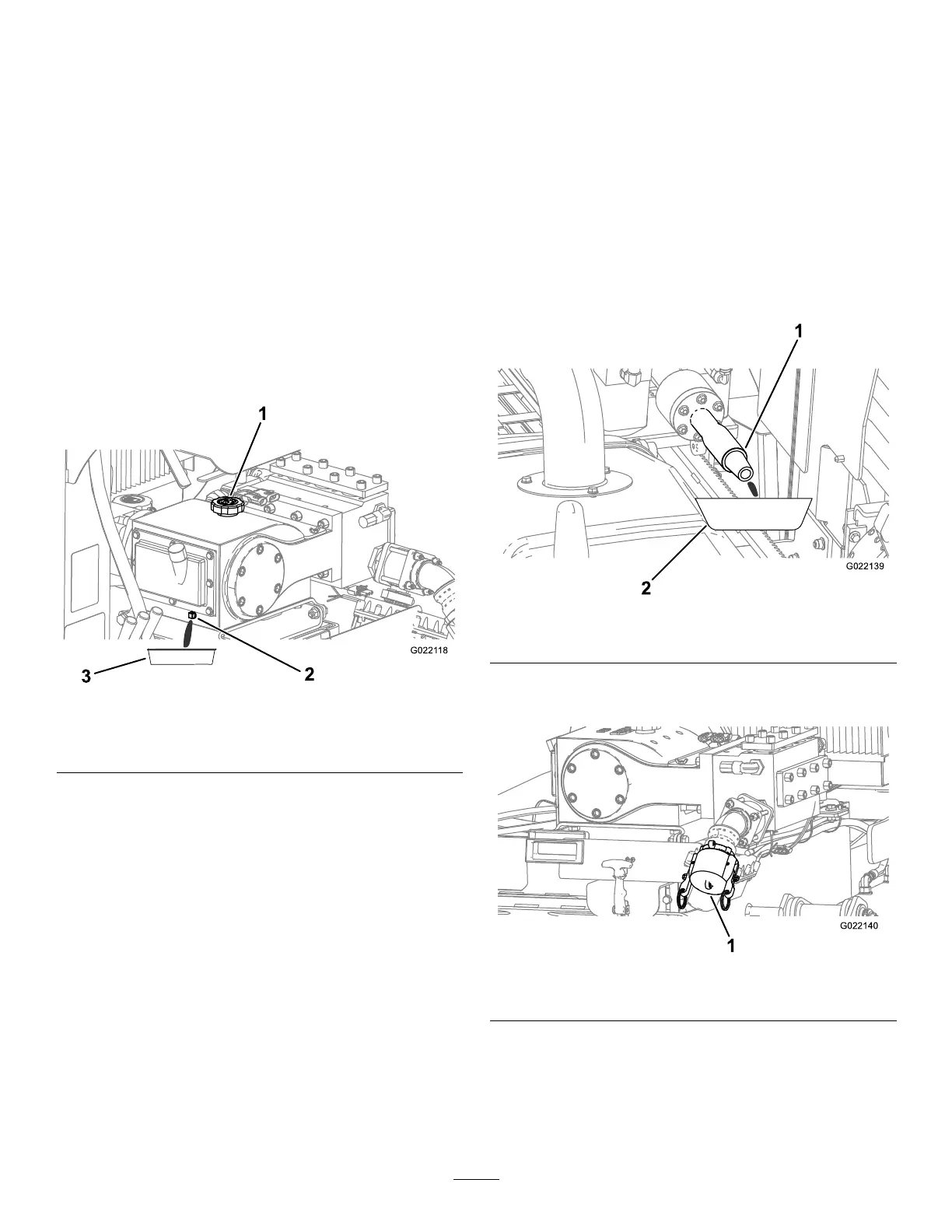

B.Placeadrainpanunderthedrillspindleforthe

leakedantifreeze(Figure113).

Figure113

1.Drillspindle2.Drainpan

C.Ensurethatthecapisinstalledonthedrilling-uid

pumpinlet(Figure114).

Figure114

1.Drilling-uidpumpinlet

D.Removethecapfromtheantifreezetankforthe

drilling-uidpump(Figure115).

87

Loading...

Loading...