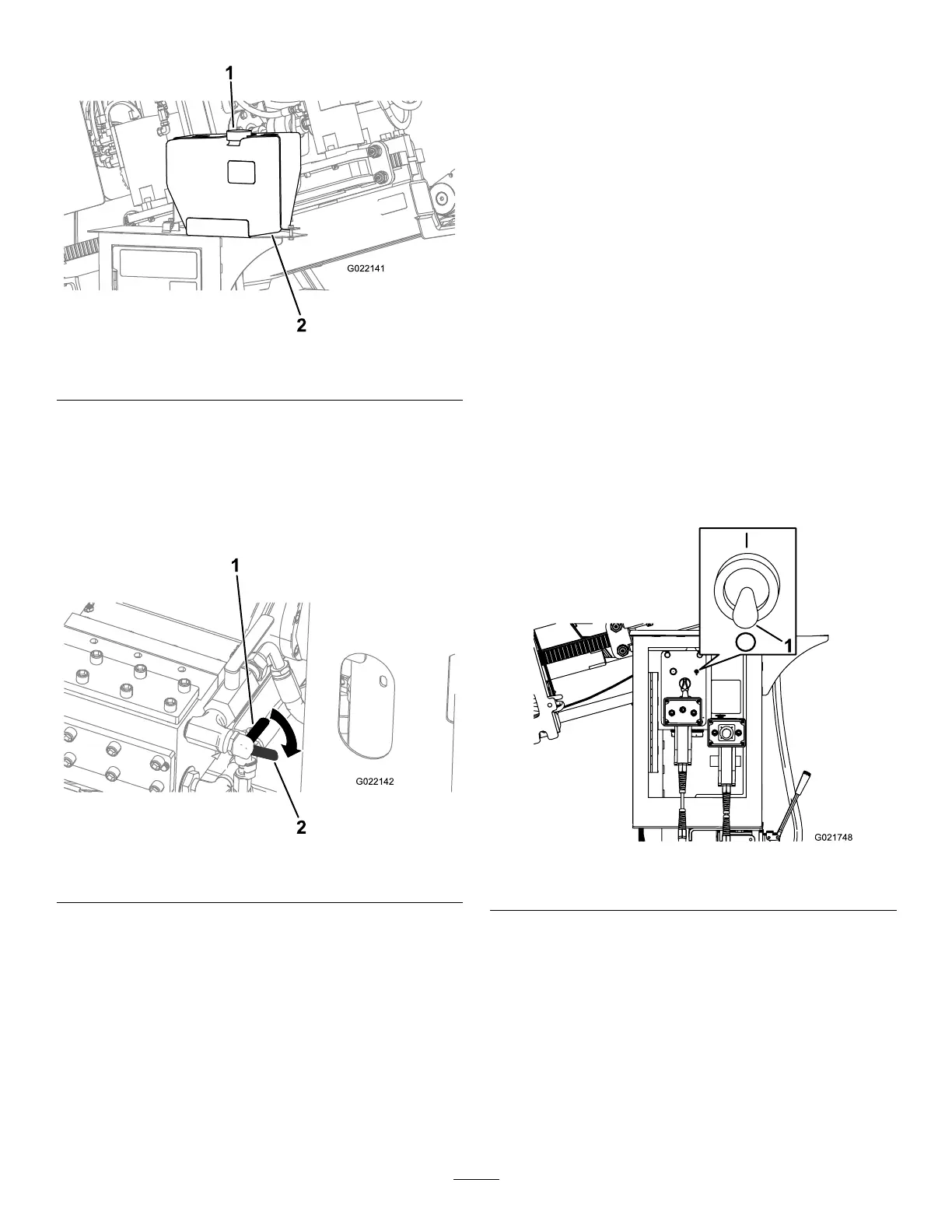

Figure115

1.Antifreeze-tankcap2.Antifreezetank

E.Ensurethatthetankisfullofantifreeze(Figure

115).

3.Circulatetheantifreezeasfollows:

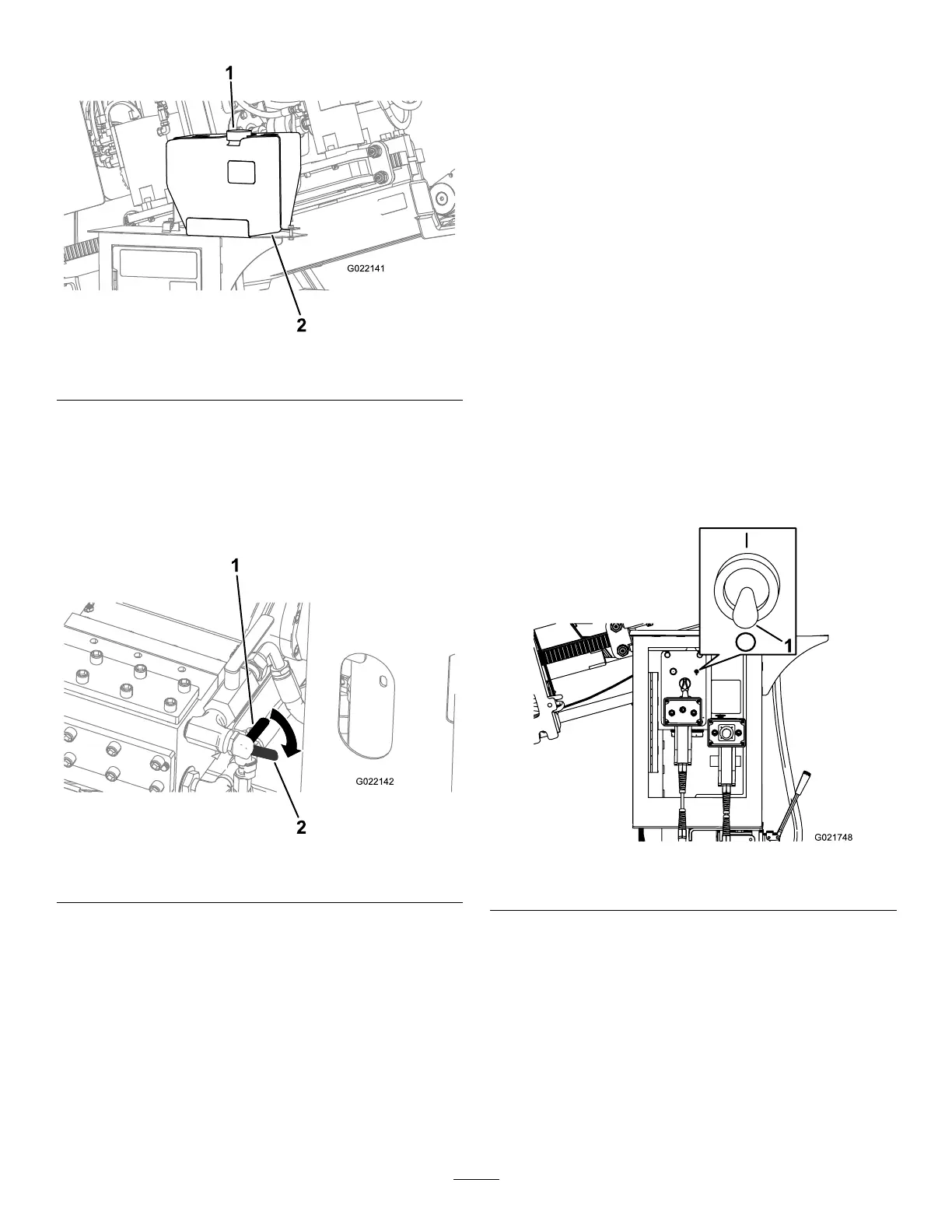

A.Opentheantifreezevalveonthefrontsideofthe

drilling-uidpump(thelowervalve)asshownin

Figure116.

Figure116

1.Valveintheclosedposition2.Valveintheopenposition

B.StartthemachineandturnOnthedrilling-uid

pump.

C.Addantifreezetothetankasneeded(Figure115).

D.Whentheantifreezecomesoutofthedrillspindle

(Figure113),turnthepumpoff.

4.Turnthemachineoff.

5.Installthecapontotheantifreezetank(Figure115).

6.Closetheantifreezevalve(Figure116).

Cleaning

CleaningwiththeSpray-Hose

Attachment

ServiceInterval:Beforeeachuseordaily

Themachinecomeswithaspray-hoseattachmentthatyou

canusetocleanthemachineandpipes.

Important:Donotsprayanyelectroniccomponentof

themachineandensurethatthehoodisdownbefore

cleaningthemachinewiththespray-hoseattachment.

Important:Iftheoutsidetemperatureisbelowfreezing,

refertoPreparingtheDrilling-FluidSystemforCold

Weather(page87)beforecleaningthemachine.

Tousethespray-hoseattachment,performthefollowing

procedure:

1.Parkthemachineonalevelsurface,stoptheengine,

andremovetheignitionkey.

2.Ensurethatthespray-hoseattachmentswitchisinthe

OFFposition(Figure117).

Figure117

1.Spray-hoseattachmentswitch(Offposition)

3.Opentherearhood.

4.Turnthedrilling-uidvalveclockwisetotheOFF

position(Figure118).

88

Loading...

Loading...