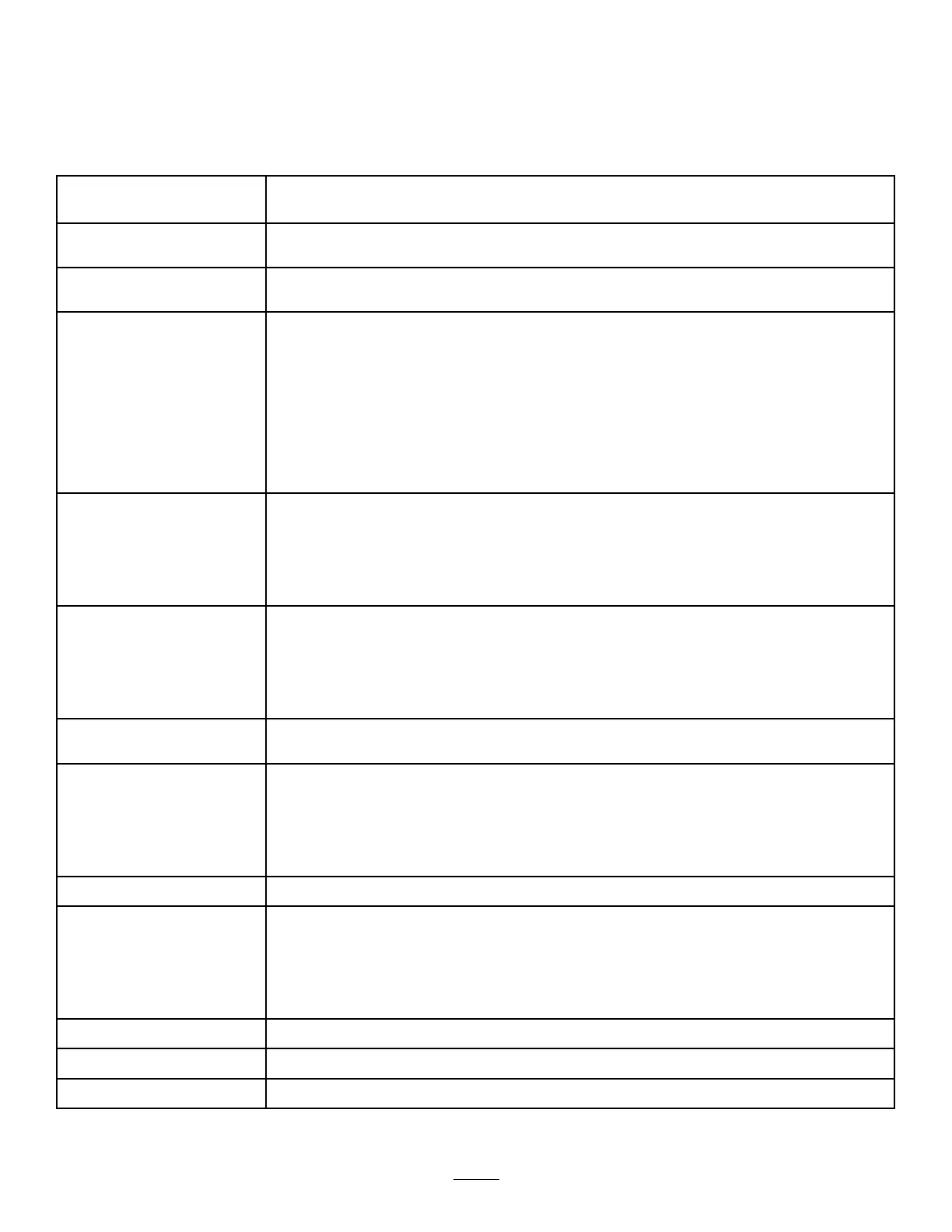

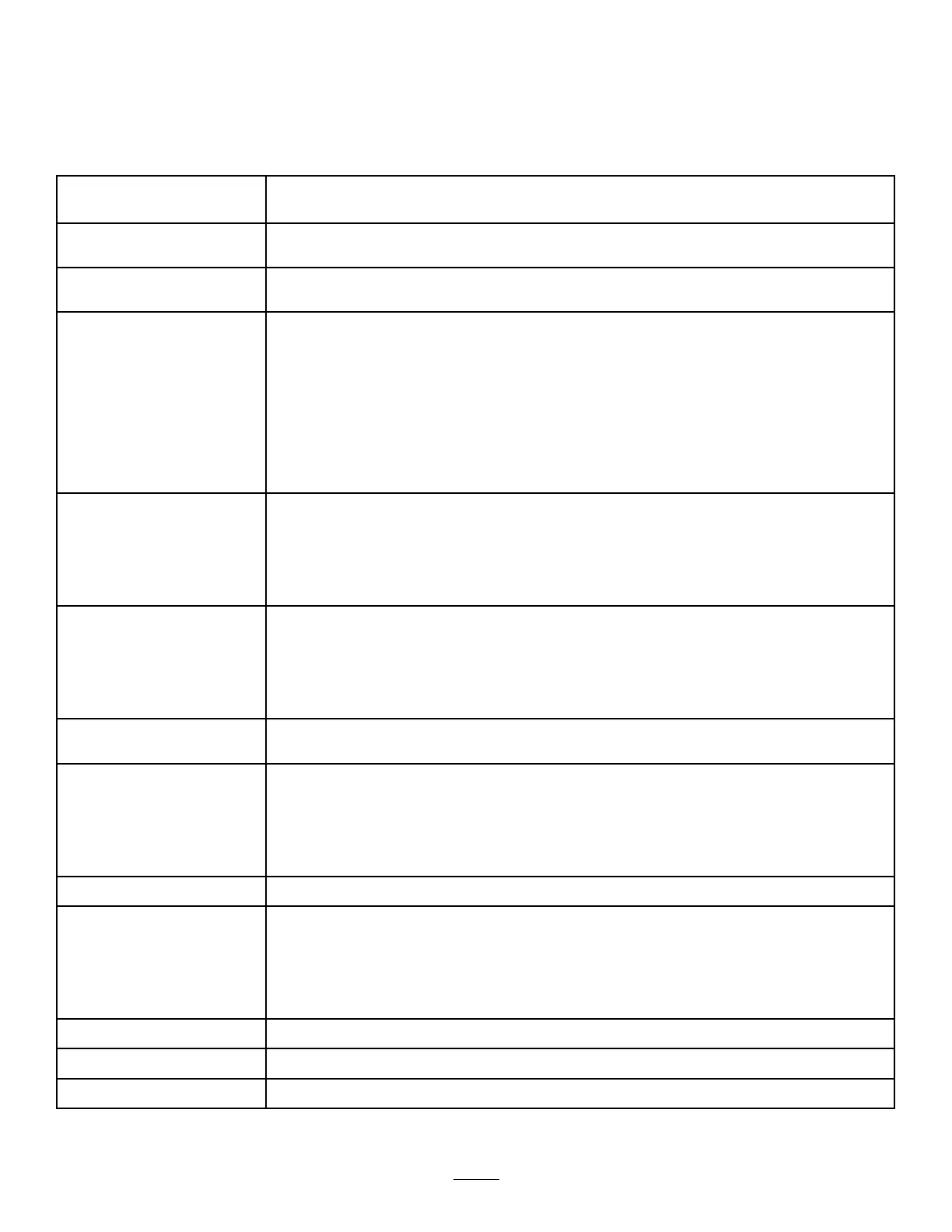

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst100hours

•Checkthegearboxdriveoil.

•Changethegearbox-driveoil.

Aftertherst250hours

•Adjustthevalveclearance.

•Changetheplanetaryoil.

Beforeeachuseordaily

•Checkthefuellevel.

•Greasethemachine.(Greaseimmediatelyaftereverywashing).

•Checkthecrankcase-venttubeandcleanitifnecessary.

•Checktheindicatoronthedisplayscreenforarestrictedairlter.

•Checktheengine-oillevel.

•Checkthetracktension.

•Checkthecoolantlevelinthereservoirfortheradiator.

•Checkthehydraulicuidlevel.

•Checkthedrilling-uid-pumpoillevel.

•Cleanthemachinewiththespray-hoseattachment.

Every50hours

•Checkandcleanthedustvalve.

•Removeaircleanercoverandcleanoutdebris.Donotremovethelter.

•Checkthefuel-waterseparatorforwaterandsediment.

•Checkthebatterycondition

•Checktheplanetary-driveoillevel(Also,checkifexternalleakageisobserved).

•Checkthecoolantlevelintheradiator.

Every250hours

•Cleanorreplacetheair-cleanerlter.

•Changetheengine-oillter.

•Changetheengineoil.

•Clearthesparkarrestorinthemuferofcarbonbuildup.

•Replacetheprimaryandsecondary,fuellters.

•Checktheconditionoftheengine-drivebelt.

Every300hours

•Checktheconditionofthecoolantsystemcomponents.Cleandirtanddebrisfrom

themandrepairorreplacethecomponentsasnecessary.

Every500hours

•Inspectthefuellinesandconnections.

•Checkthegearboxdriveoil(oryearly,whichevercomesrst).

•Changethegearbox-driveoil(oryearly,whichevercomesrst).

•Changethehydraulic-uidreturnlter.

•Changethehydraulic-pressurelter.

•Changethedrilling-uidpumpoil.

Every800hours

•Changetheplanetaryoil(oryearly,whichevercomesrst).

Every1,000hours

•Drainandcleanthefueltank.

•Checktheconcentrationofthecoolantbeforethewinterseason.

•Cleanthecoolingsystem.(Cleanthecoolingsystemifthecoolantbecomesdirtyor

rustcolored.)

•Checkthetensionontheenginedrivebelt.

•Changethehydraulicuid.

Every2,000hours

•Adjustthevalveclearance.

Yearlyorbeforestorage

•Touchupchippedpaint.

Every2years

•Replacemovinghoses.

Important:Refertoyour

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

57

Loading...

Loading...