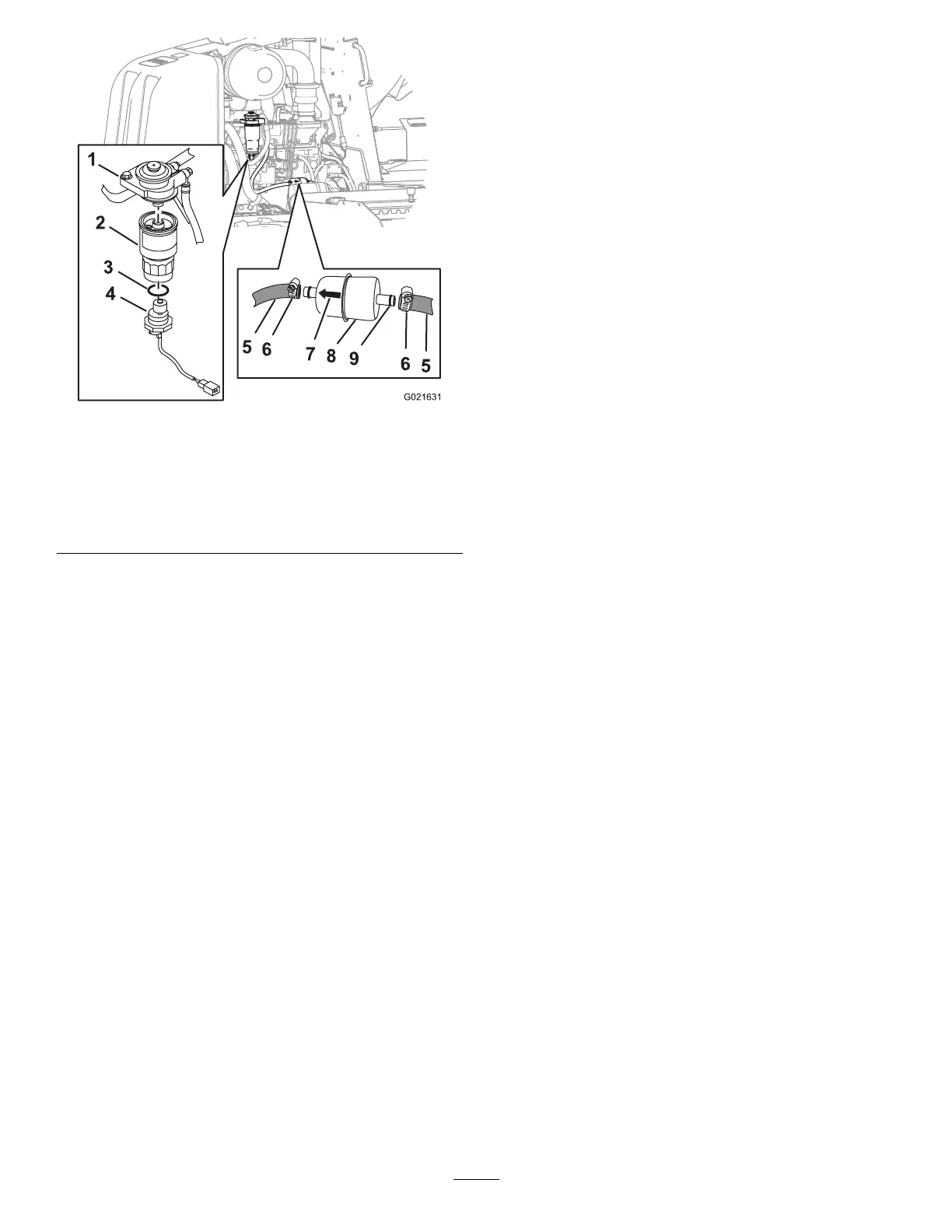

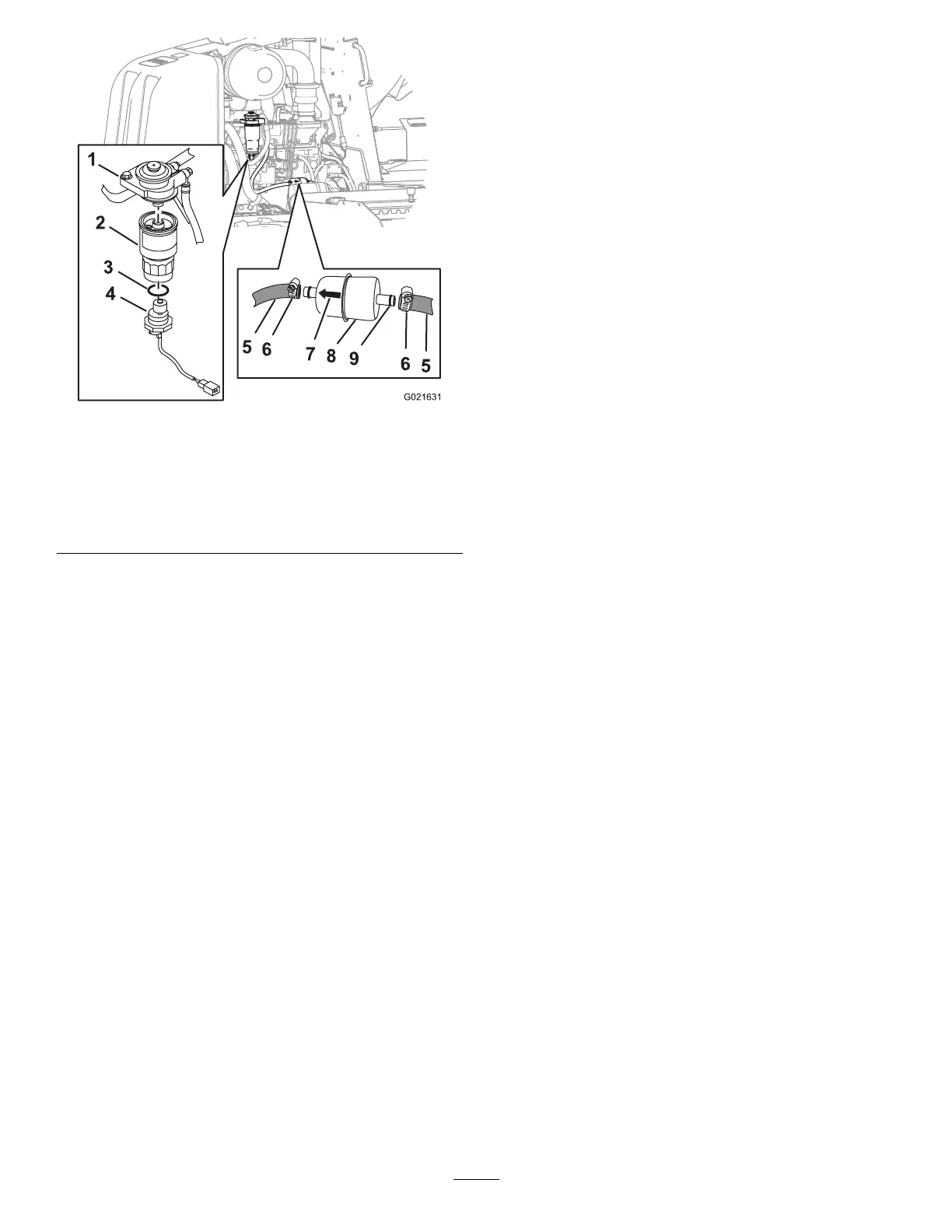

Figure92

1.Filteradapter6.Hoseclamp

2.Secondary-lterelement

7.Arrow

3.O-ring8.Primaryfuellter

4.Watersensor9.Fitting

5.Fuelsensor

D.Firmlygraspthesecondary-fuel-lterelement,

androtateitcounterclockwise,andremovethe

lterfromthelteradapter(Figure92).

Note:Discardthelterelement.

E.Cleanthelteradapterwithacleanrag.

2.Installthesecondary,fuellterasfollows:

A.Applyathinlmofcleanfueltothesealonthe

fuel-lterelement.

B.Alignthenewsecondary-lterelementtothe

lteradapter(Figure92).

C.Rotatethesecondary-lterelementuntiltheseal

contactsthelteradapter,thenrotatethelter

elementanadditional3/4turn.

Important:Donotusealterwrenchto

tightenthelter.Youcoulddamagethelter

andcausealeak.

D.AlignthenewO-ringoverthewatersensor

(Figure92).

E.Alignthewatersensortothebottomofthe

secondary,fuellter(Figure92).

F.Firmlygraspthesecondary-lterelementand

rotatethewatersensorclockwiseuntilhand-tight

(Figure92).

3.Primethefuelsystem;refertoPrimingtheFuel

System(page70).

4.Starttheengineandcheckforleaksatthefuellters.

CheckingFuelLinesand

Connections

ServiceInterval:Every500hours/Yearly(whichever

comesrst)—Inspectthefuellinesand

connections.

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.

DrainingandCleaningtheFuel

Tank

ServiceInterval:Every1,000hours/Yearly(whichever

comesrst)—Drainandcleanthefuel

tank.

Drainandcleanthetankifthefuelsystembecomes

contaminatedorifthemachinewillbestoredforanextended

periodoftime.Usecleanfueltoushoutthetank.Referto

DrainingWaterfromtheFuelTank(page69)fordraining

instructions.

Note:Performthisprocedurewhenthefuellevelislow,to

avoidtheneedtodrainlargevolumesoffuel.

71

Loading...

Loading...