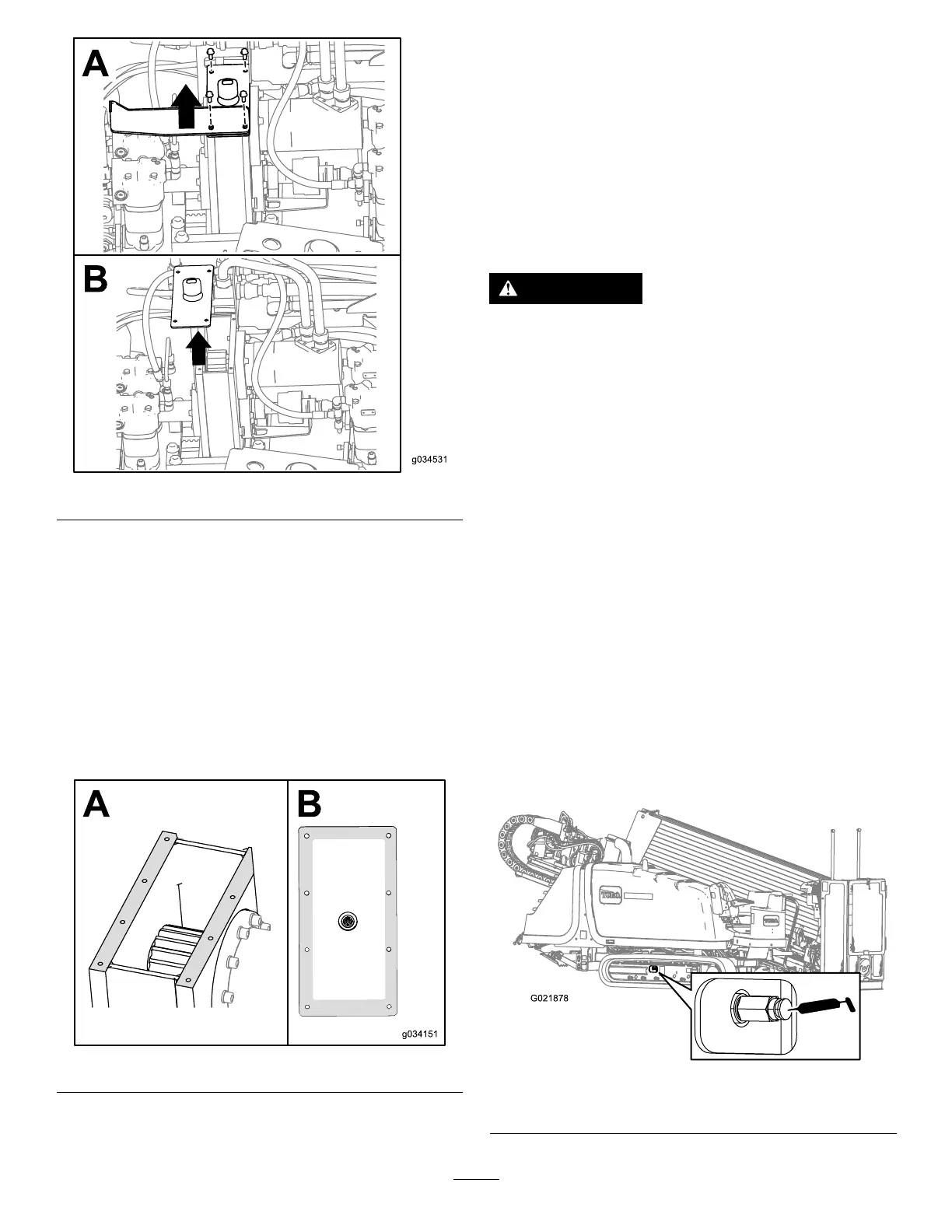

Figure97

2.Stoptheengineandremovetheignitionkey.

3.Removethe4boltsontheguardplateandgearbox

(BoxAofFigure97).

4.Removetheguardplate(BoxAofFigure97).

5.Removethecoveronthegearboxandsyphontheoil

out(BoxBofFigure97).

6.Fillthegearboxwithoiluntiltheoillevelinthesight

glassismorethanhalffull(Figure96).

7.Cleanthesealantoffofthegearboxboxandcover

(Figure98).

Figure98

8.Putnewautomotive-gradeRTVsealantaroundthe

edgeofthecover(BoxBofFigure98).

9.Placetheguardbackintoplaceandinstallthe2bolts

(BoxAofFigure97).

10.Installthe2otherboltssecuringthelidontothe

gearbox(BoxAofFigure97).

11.Torquetheboltsto23to29N∙m(17to21ft-lb).

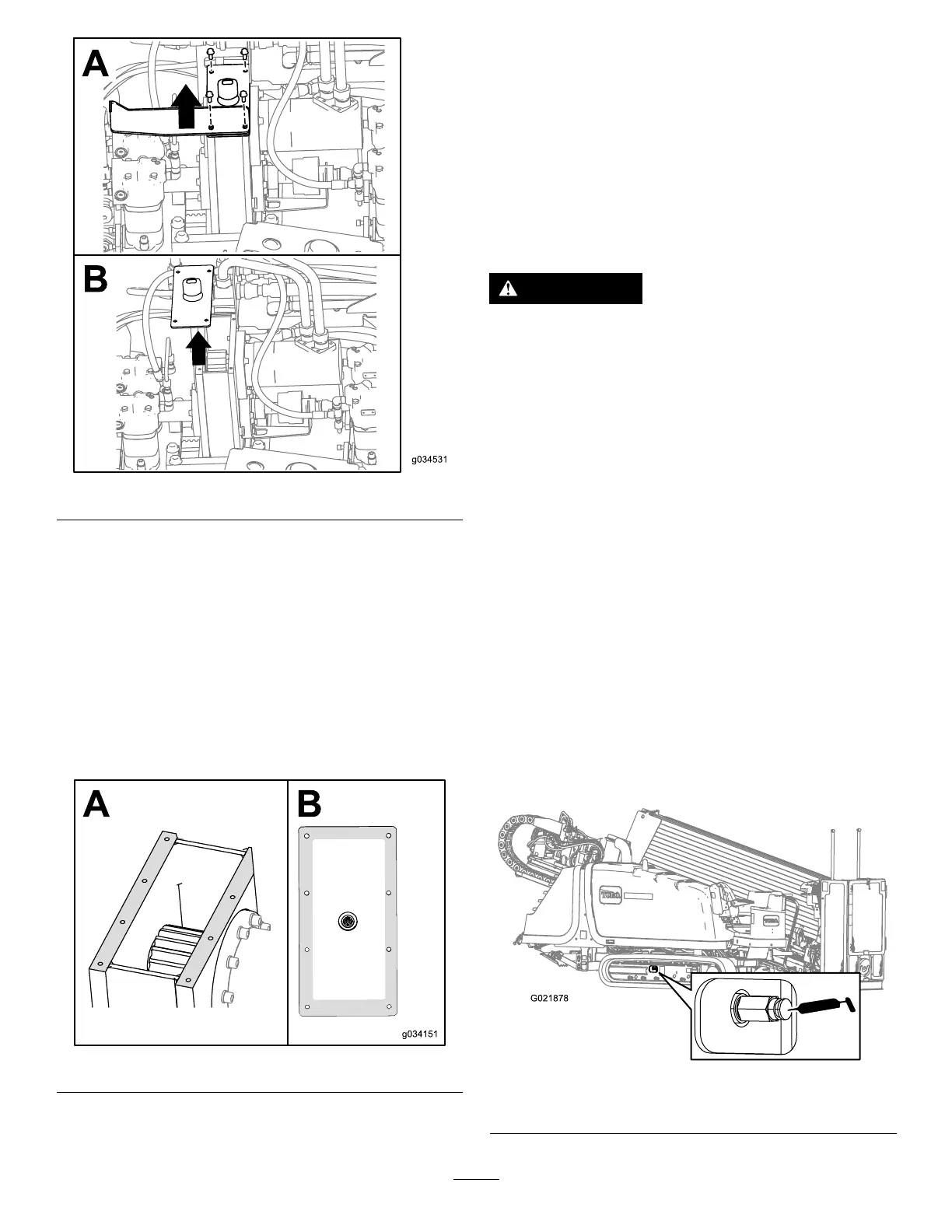

ServicingtheTracks

ServiceInterval:Beforeeachuseordaily—Checkthetrack

tension.

WARNING

Greaseinthehydraulictrackishighlypressurized;

ensurethatthetrack-tensiongreasevalveisnot

loosenedmorethanonerevolutionatatime.

Ifyouremovethetrack-tensiongreasevalvefound

inthehydraulic-tracktensionerorloosenittoo

much,greasecanbereleasedandmaycause

seriousinjuryordeath.

TighteningtheTrackTension

Ifthetrackseemsloose,tightenthetracktensionasfollows:

1.Parkthemachineonalevelsurface,stoptheengine,

andremovetheignitionkey.

2.Removedirtanddebrisfoundaroundthetrack-tension

greasevalve(Figure99).

Important:Ensurethattheareasurrounding

thetrack-tensiongreasevalveiscleanbefore

beginningtoadjustthetracktension.

3.Removetheretainingboltsandcoverthathousethe

track-tensiongreasevalve.

4.Applygreasetothettinguntilthetensionreaches

22,063kPa(3,200psi)asshowninFigure99.

Figure99

Track-tensiongreasevalveshown

76

Loading...

Loading...