Maintenance

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Note:Downloadafreecopyoftheelectricalor

hydraulicschematicbyvisitingwww.Toro.comand

searchingforyourmachinefromtheManualslinkon

thehomepage.

MaintenanceSafety

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethepowertakeoffandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovementtostop.

•Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifthecuttingunitsareinthetransportposition,use

thepositivemechanicallock(ifequipped)before

youleavethemachineunattended.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Supportthemachinewithjackstandswhenever

youworkunderthemachine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened,especially

blade-attachmenthardware.

•Replaceallwornordamageddecals.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

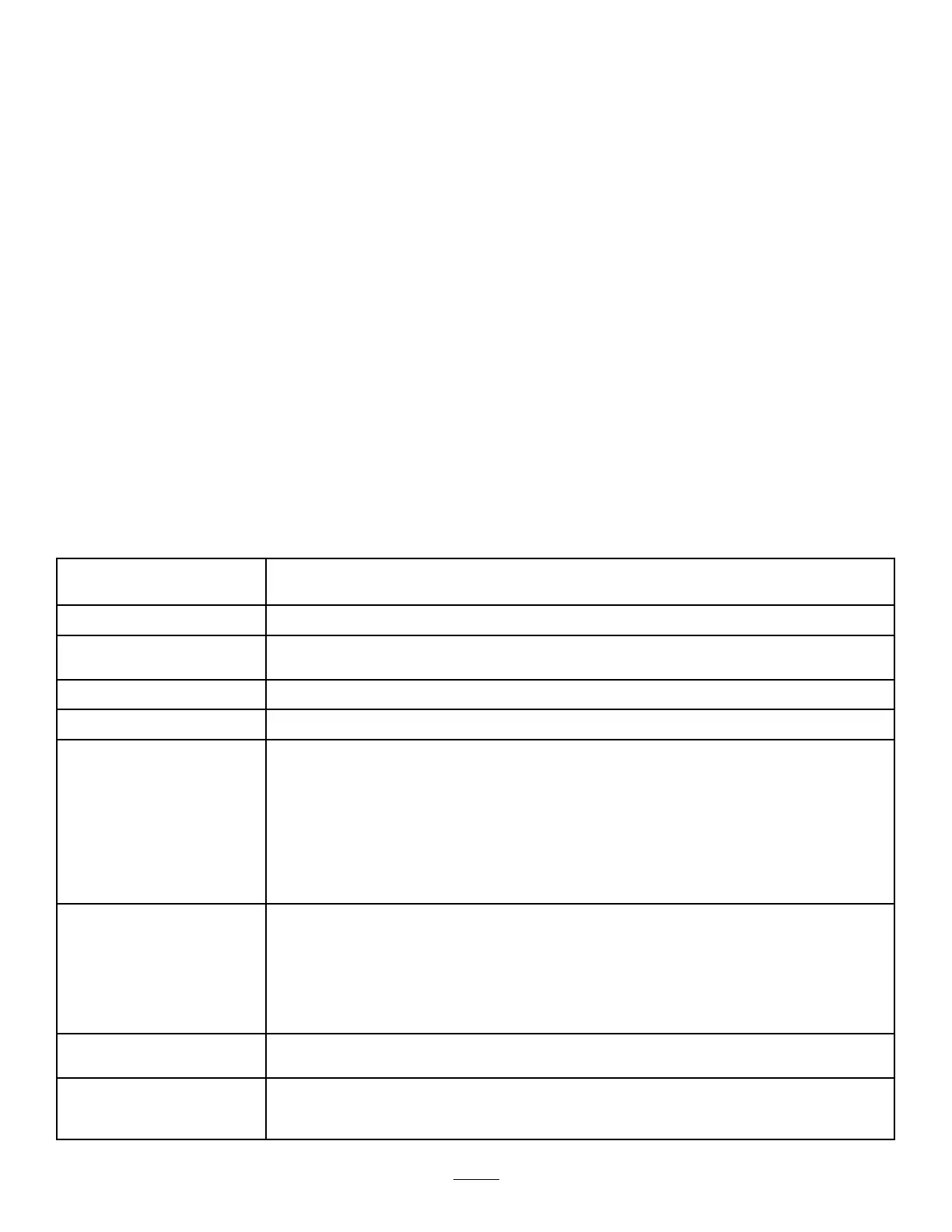

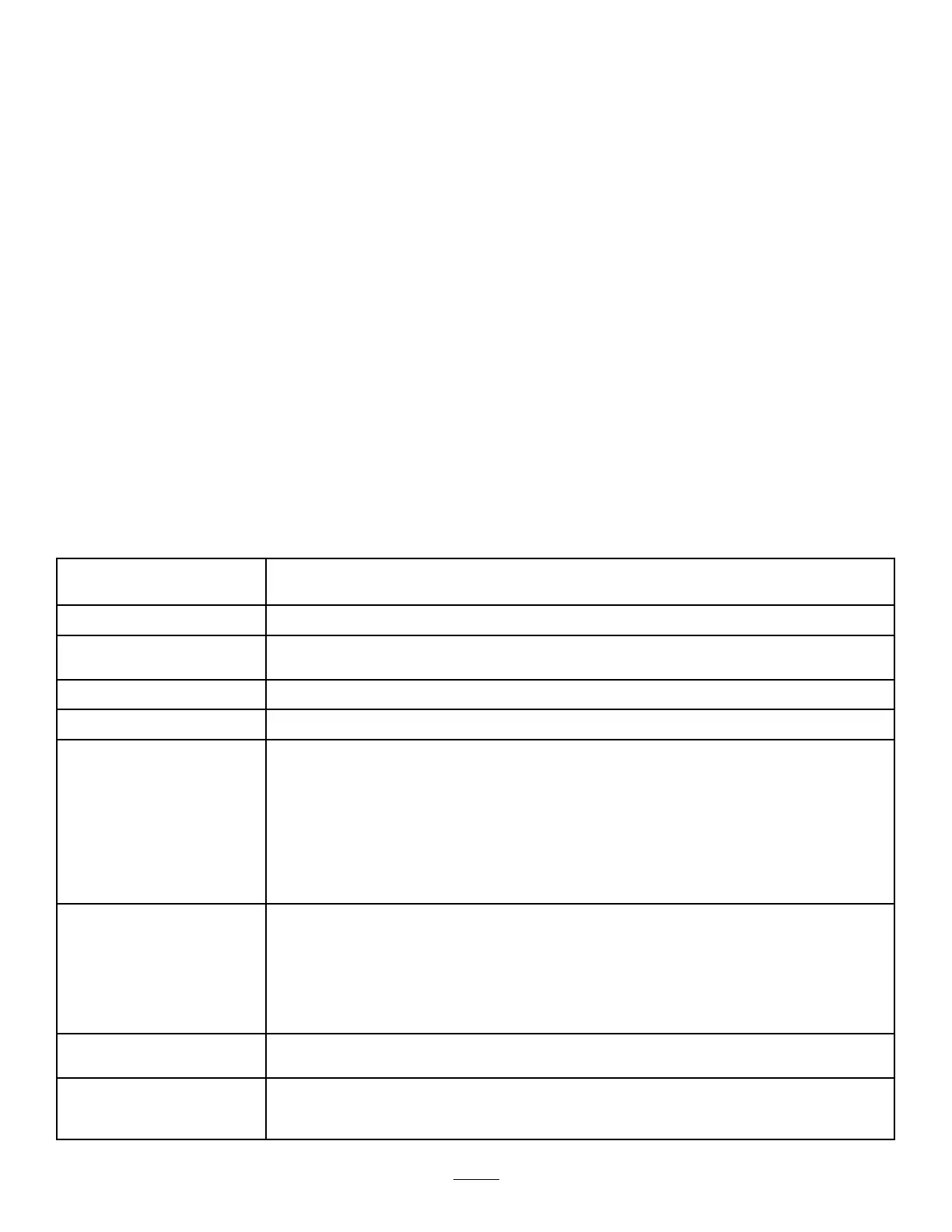

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Torquethewheel-lugnuts.

Aftertherst10hours

•Torquethewheel-lugnuts.

•Checkthealternator-belttension.

Aftertherst50hours

•Checkthealternator-belttension.

Aftertherst1000hours

•Changethehydraulicuidandhydrauliclter.

Beforeeachuseordaily

•Checktheairpressureinthetires.

•Checktheinterlocksystem.

•GreasethePTOdriveshaft(cross-bearingsandtelescopingsplines).

•Checktheengine-oillevel.

•Checktheair-cleanerrestrictionindicatorandreplacethelterelementsifnecessary.

•Checkthecoolingsystemandthecoolantlevel.

•Removedebrisfromtheenginearea,oilcooler,fuelcooler,andradiator(cleanthem

morefrequentlyindirtyordustyconditions).

•Checkthehydraulic-uidlevel.

Every50hours

•Greasethebearingsandbushings.

•Drainwaterorothercontaminantsfromthefuel/waterseparator.

•Checkthebattery-cableconnections.

•Checkthebatterycondition;cleanthebatteryifneeded.

•Checkthebattery-electrolytelevelwheninoperation(ifapplicable).

•Checkthehood-air-intakescreen.

•Checkandcleanthehood-air-intakescreen.

Every100hours

•Checkthealternator-beltconditionandtension.

•Checkthetraction-beltcondition.

Every200hours

•Torquethewheel-lugnuts.

•Inspectthecooling-systemhoses.

•AdjustthePTO-clutchgap.

38

Loading...

Loading...