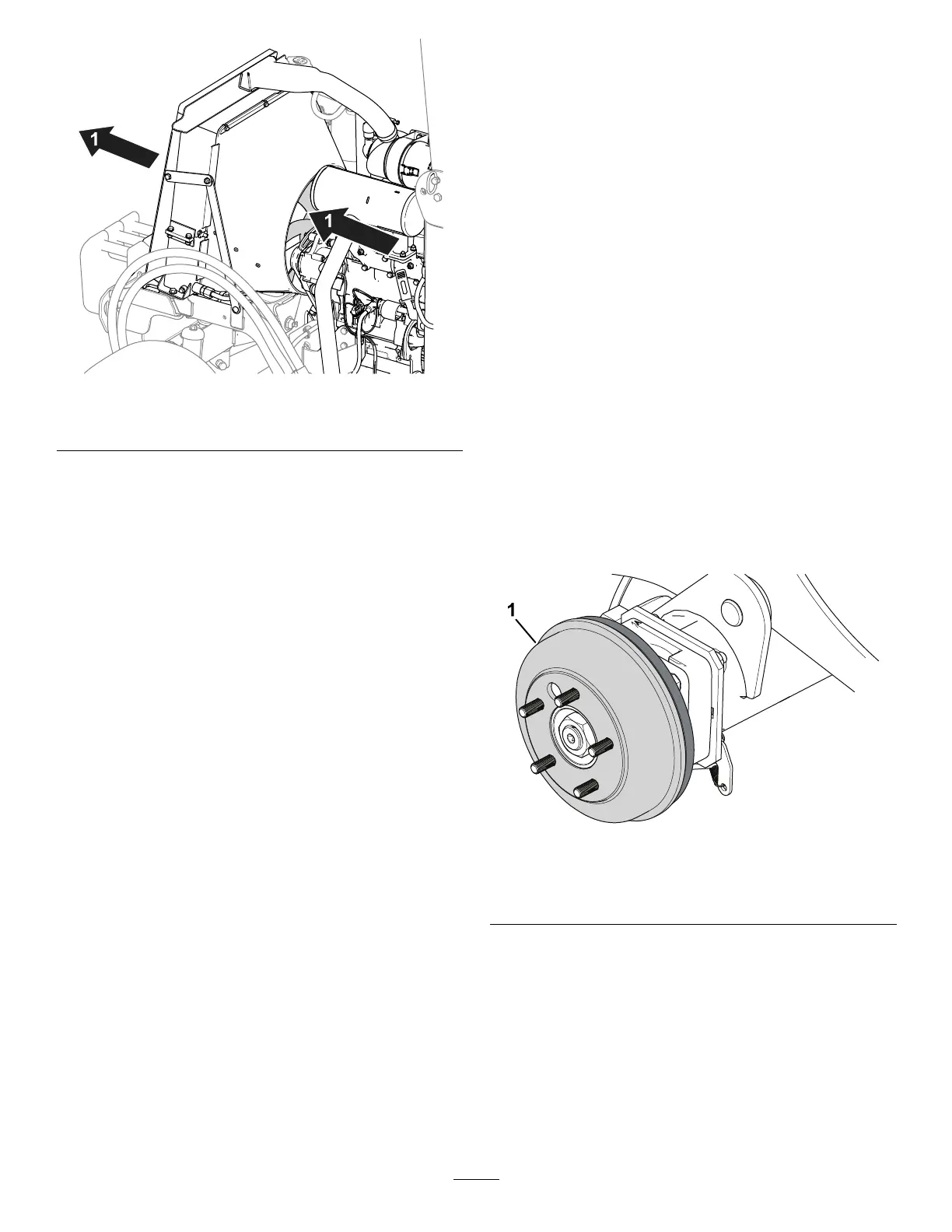

g299819

Figure65

1.Compressed-airdirection

•Straightenanybentns.

Inspectingthe

Cooling-SystemHoses

ServiceInterval:Every200hours

Inspectthecooling-systemhosesforleaks,kinked

lines,loosemountingsupports,wear,loosettings,

weatherdeterioration,andchemicaldeterioration.

Makeallnecessaryrepairsbeforeoperatingthe

machine.

BrakeMaintenance

CheckingandAdjustingthe

ParkingBrake

ServiceInterval:Every400hours

CheckingtheParkingBrake

1.Placejackstandsunderthefrontofthemachine;

refertoRaisingtheFrontoftheMachine(page

40).

2.Removethefrontwheels.

3.MovetheparkingbraketotheDISENGAGED

position;refertoParkingBrake(page20).

4.Removethebrakedrums(Figure66)byhand.

•Ifyoufeelresistancewhileremovingthe

brakedrumsbyhand,anadjustmentisnot

needed.

•Ifyoudonotfeelresistancewhileremoving

thebrakedrumsbyhand,anadjustmentis

needed;refertoAdjustingtheParkingBrake

(page54).

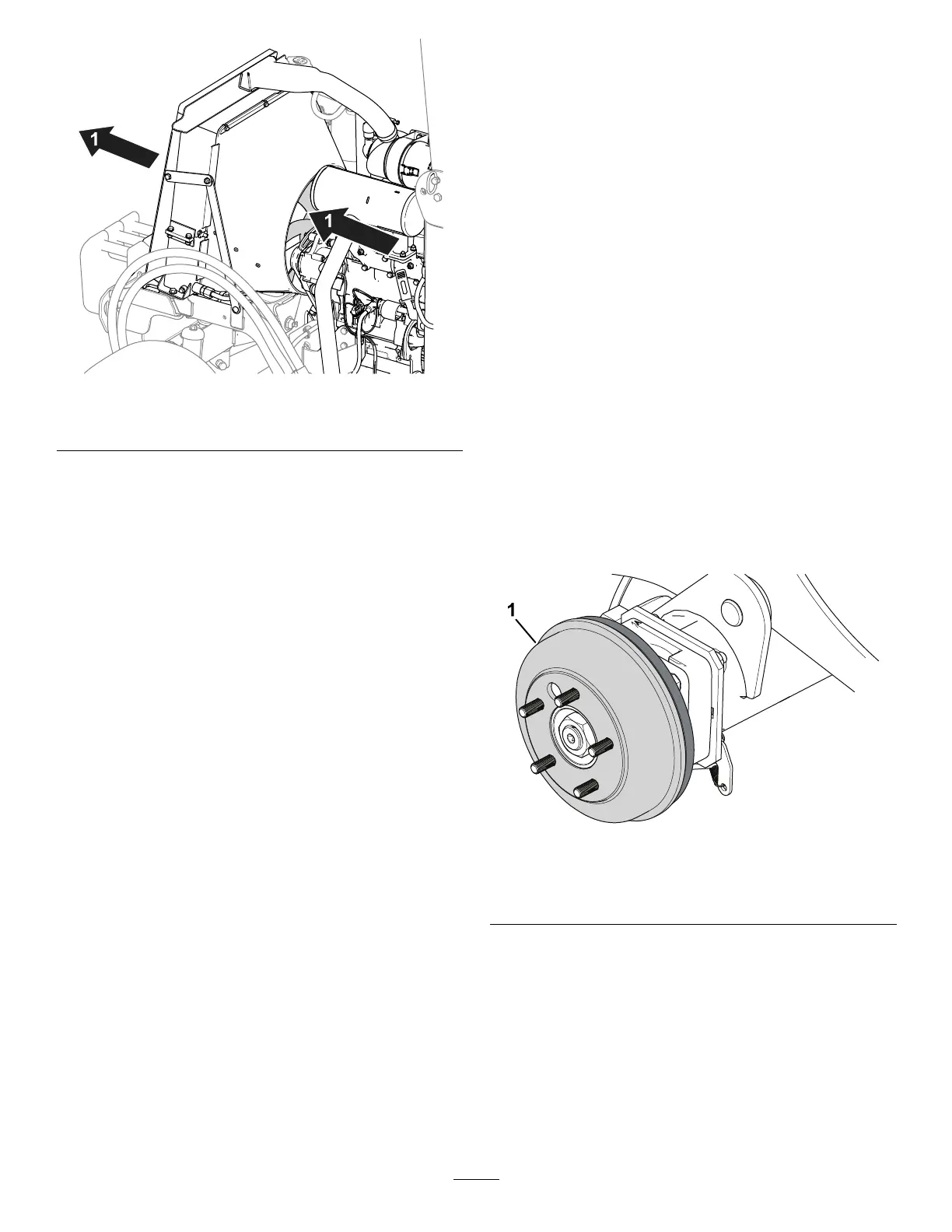

g312869

Figure66

Rightsideofthemachineshown.

1.Brakedrum

5.Installthefrontwheelsandtorquethelugnuts;

refertoT orquingtheWheel-LugNuts(page52).

AdjustingtheParkingBrake

1.Chockthewheels.

2.Ensurethattheparkingbrakeisdisengaged.

3.Locatethebrake-cablemount(Figure67)under

theleftsideofthemachineneartheleftwheel.

54

Loading...

Loading...