33

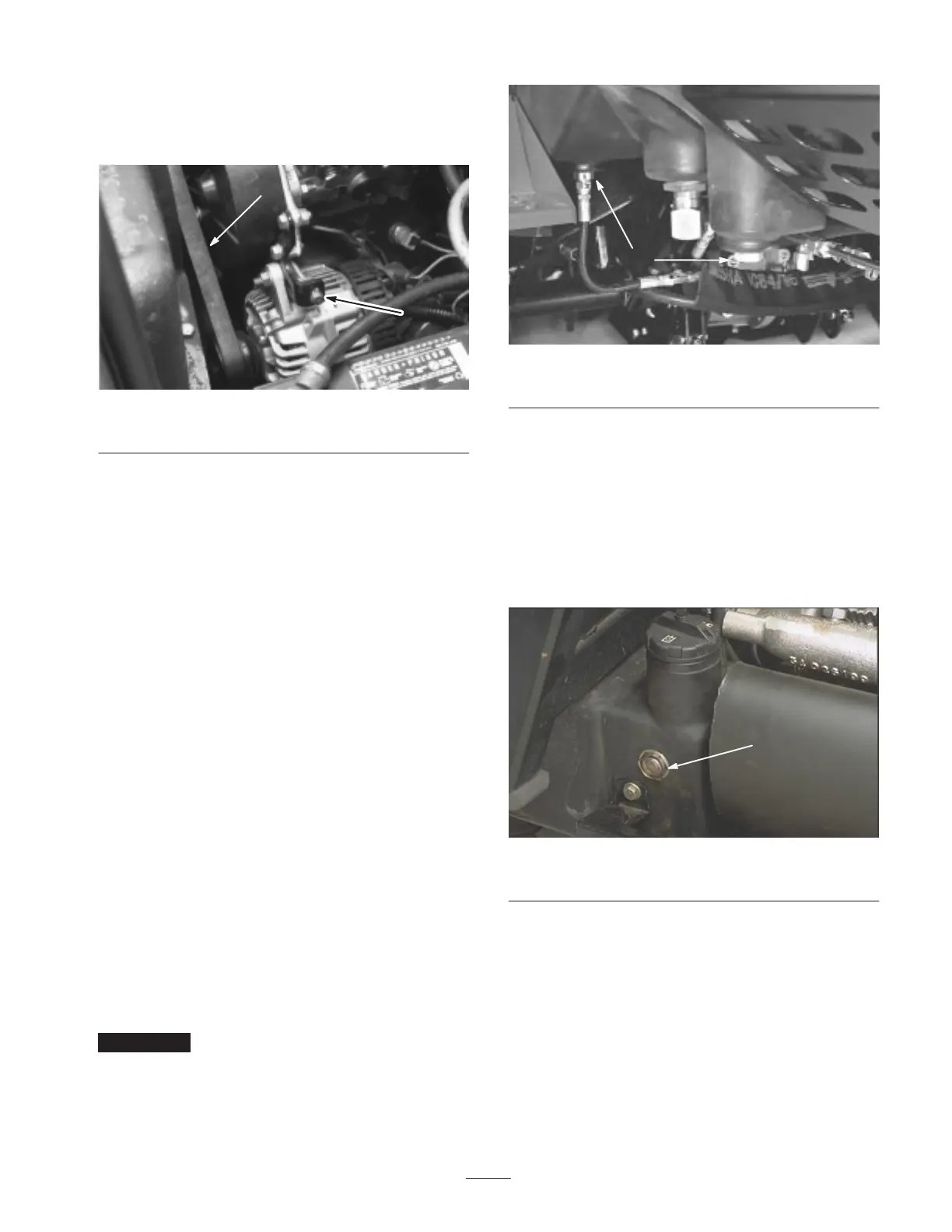

2. If deflection exceeds 1/4 in. (6 mm), loosen alternator

mounting bolts. Adjust alternator belt tension by

adjusting tension screw (Fig. 45). Check deflection of

belt again to assure tension is correct.

1

2

Figure 45

1. Fan belt 2. Adjusting screw

Checking the Engine Timing

Belt

Inspect engine timing belt every 800 hours of operation or

yearly.

Remove covers and check for worn, cracked, or oil soaked

belt.

Note: A new belt should be installed any time belt is

removed or loosened.

Changing the Hydraulic Oil

Change hydraulic oil filter initially after the first 50 hours

of operation, thereafter change hydraulic oil and filter after

every 800 operating hours. If oil becomes contaminated,

contact your local Toro distributor because the system must

be flushed. Contaminated oil looks milky or black when

compared to clean oil.

1. Turn engine off, release hood latch, and raise hood.

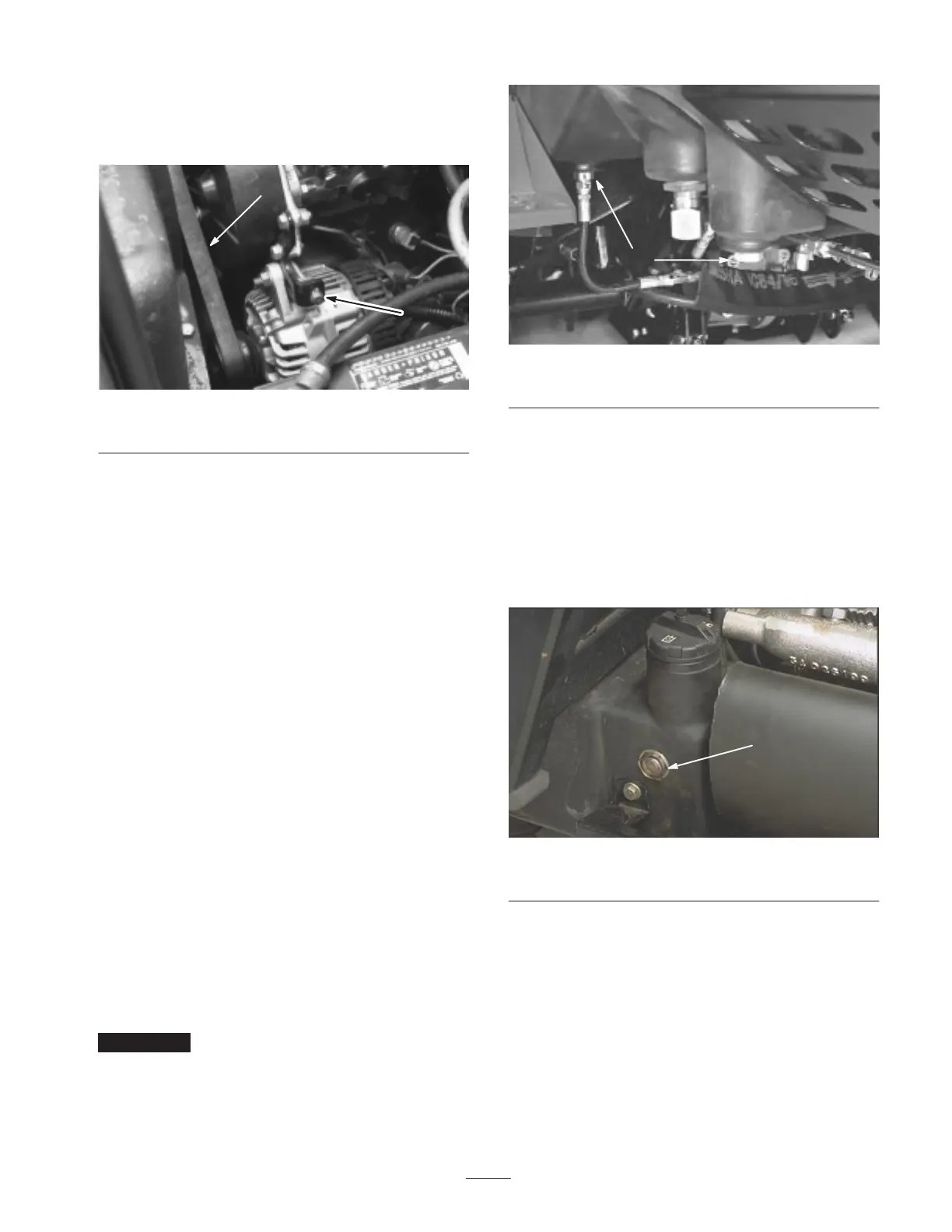

2. Remove drain plug from rear of reservoir and hydraulic

line from front of reservoir (Fig. 46) and let hydraulic

oil flow into drain pan. Reinstall and tighten plug and

line when hydraulic oil stops draining.

3. Fill reservoir with approximately 6.5 gallons (24.6 l) of

hydraulic oil; refer to Checking the Hydraulic Circuit

Oil, page 12.

Important Use only hydraulic oils specified. Other

fluids could cause system damage.

1

Figure 46

1. Hydraulic reservoir drain

4. Install reservoir cap, lower hood, and latch. Start engine

and use all hydraulic controls to distribute hydraulic oil

throughout the system. Also check for leaks. Then stop

the engine.

5. With wing decks raised, center deck down and oil

warm, look into sight gauge (Fig. 47). If hydraulic oil is

not visible, add enough oil to raise level to middle

(maximum) of sight gauge. To prevent over filling, do

not fill if oil is cold. Do not overfill.

1

Figure 47

1. Sight gauge

Loading...

Loading...