45

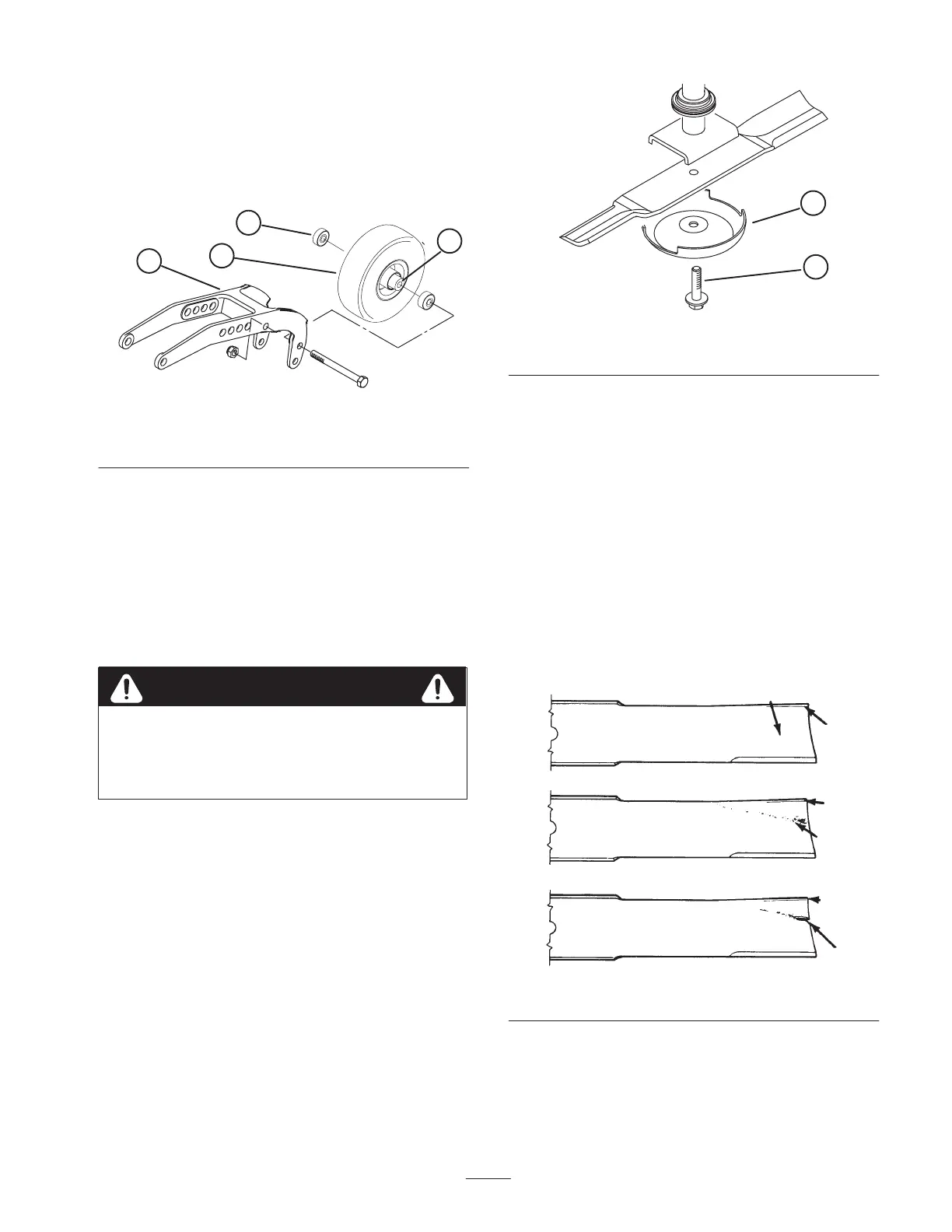

4. To assemble the castor wheel, push bearing into wheel

hub. Slide bearing spacer into wheel hub. Push other

bearing into open end of wheel hub to captivate the

bearing spacer inside the wheel hub.

5. Install castor wheel assembly between castor fork and

secure in place with capscrew and locknut.

1

3

2

4

Figure 79

1. Castor wheel

2. Rear castor pivot arm

3. Bearing (2)

4. Bearing spacer

Removing and Installing the

Blade

The blade must be replaced if a solid object is hit, the blade

is out of balance or if the blade is bent. Always use genuine

Toro replacement blades to be sure of safety and optimum

performance. Never use replacement blades made by other

manufacturers because they could be dangerous.

Do not try to straighten a blade that is bent, and

never weld a broken or cracked blade. Always use

a new blade to assure continued safety certification

of the product.

Warning

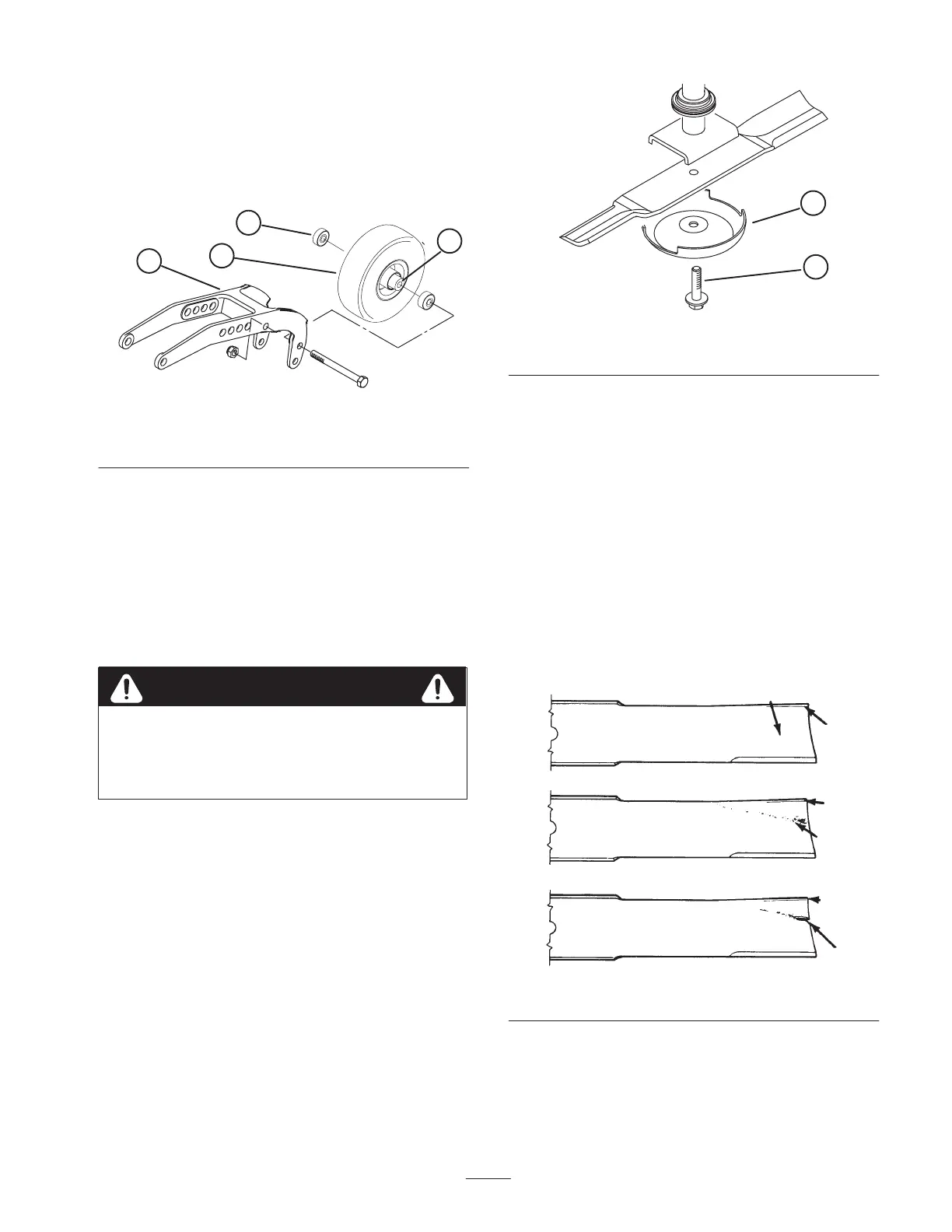

1. Raise cutting unit to highest position, shut the engine

off and engage the parking brake. Engage transport

latches to prevent cutting unit from falling accidentally.

2. Grasp end of blade using a rag or thickly padded glove.

Remove blade bolt, anti-scalp cup, and blade from

spindle shaft.

3. Install blade, sail facing toward cutting unit, with

anti-scalp cup and blade bolt. Tighten blade bolt to

85–110 ft.-lb. (116–150 N⋅m).

1

2

Figure 80

1. Blade bolt 2. Anti-scalp cup

Inspecting and Sharpening the

Blade

1. Raise cutting unit to highest position, shut the engine

off and engage the parking brake. Engage transport

latches to prevent cutting unit from falling accidentally.

2. Examine cutting ends of the blade carefully, especially

where the flat and curved parts of the blade meet

(Fig. 81-A). Since sand and abrasive material can wear

away the metal that connects the flat and curved parts of

the blade, check the blade before using the machine. If

wear is noticed (Fig. 81-B), replace the blade; refer to

Removing and Installing the Blade, page 45.

A

B

C

SAIL

SAIL

FLAT PART

OF BLADE

SLOT

FORMED

WEAR

SAIL

Figure 81

Loading...

Loading...