38

1. Remove 2 screws securing PTO belt cover to adapter

plate (Fig. 60) and 1 screw securing belt cover to tab on

spring anchor. Remove cover.

1

2

Figure 60

1. PTO belt cover 2. Adapter plate

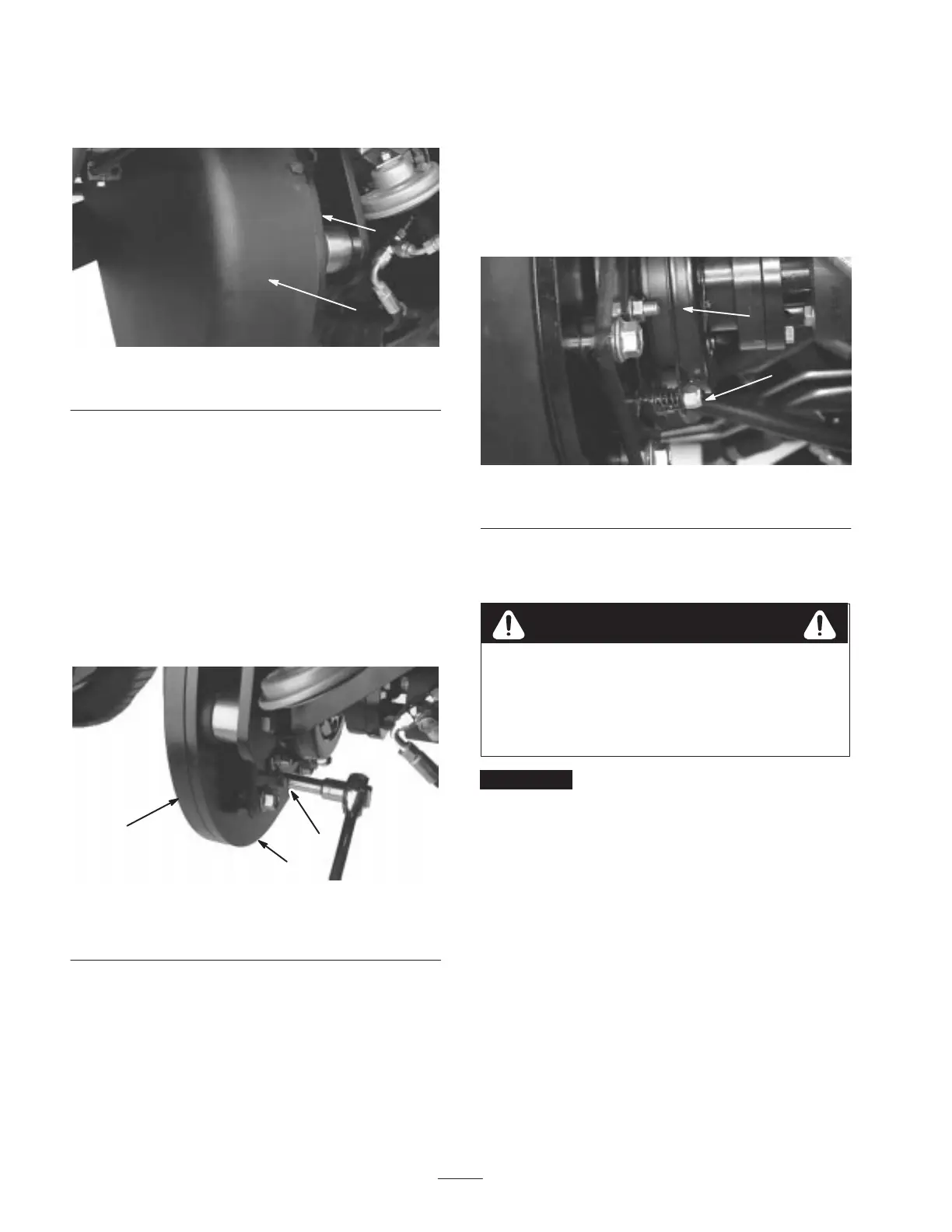

2. Loosen 3 flange screws and flange nuts securing

adapter plate to clutch plate (Fig. 61).

3. Insert end of 1/2 in. (13 mm) drive, 20 in. (51 cm) long,

torque wrench into square hole in clutch plate (Fig. 61).

With wrench handle parallel to ground, pull wrench

upward until 180 ft.-lb. (246 N⋅m) of torque is applied

to tension belt.

4. Tighten flange screws and flange nuts locking

adjustment.

5. Reinstall PTO belt cover with screws previously

removed.

1

2

3

Figure 61

1. PTO belt

2. Adapter plate

3. Square hole

Adjusting the Clutch

The PTO clutch is adjustable to ensure proper engagement

and blade braking. Check clutch adjustment initially after

the first 10 hours of operation, thereafter, check every 200

hours.

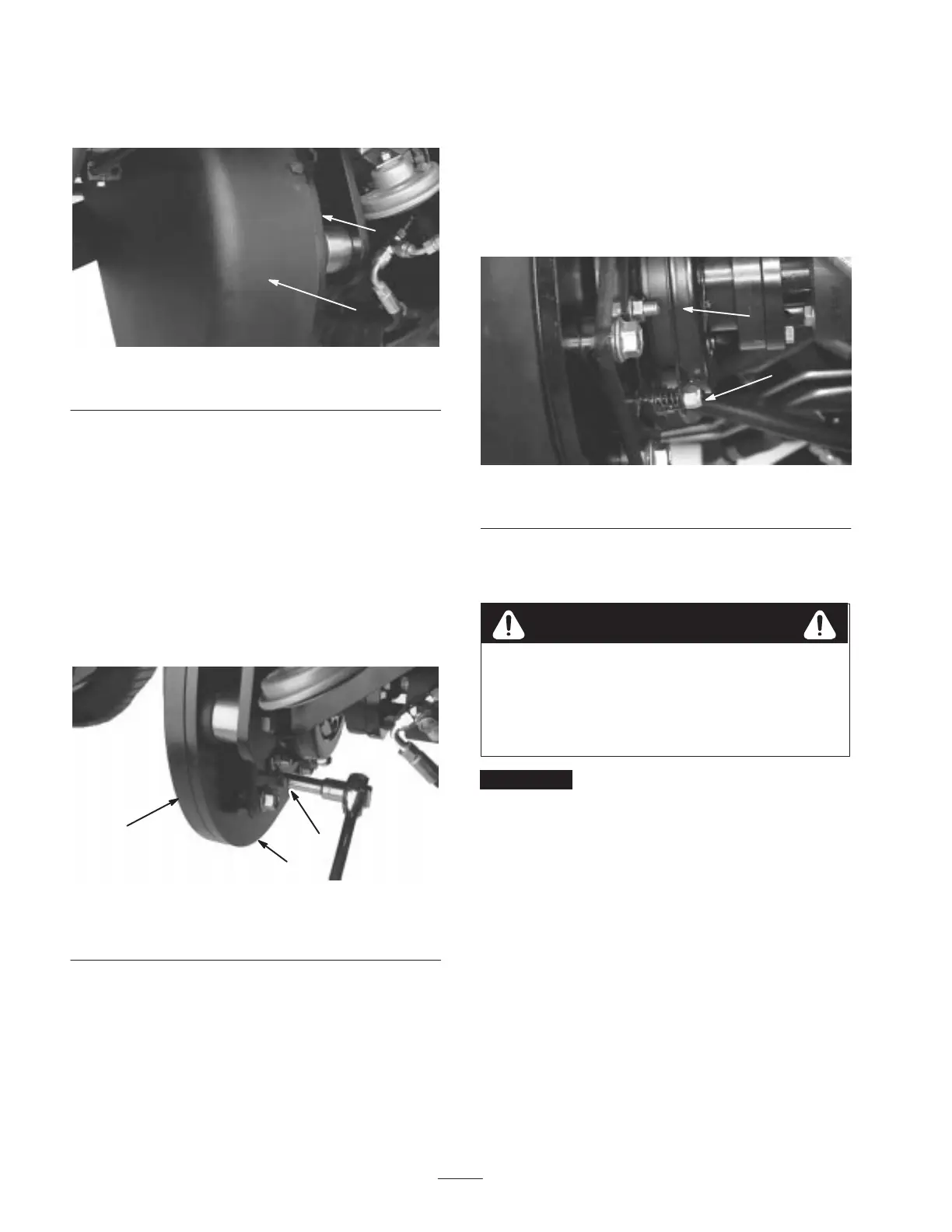

1. To adjust clutch, tighten or loosen locknuts on flange

studs.

2. Check adjustment by inserting feeler gauge through

slots next to flange studs (Fig. 62).

3. The proper disengaged clearance between the clutch

plates is 0.011–0.021 inches (0.28–0.53 mm). It will be

necessary to check this clearance at each of the three

slots to ensure the plates are parallel to each other.

1

2

Figure 62

1. Clutch 2. Flange studs

Servicing the Battery

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

Warning

Important Before welding on the machine, disconnect

ground cable from the battery to prevent damage to the

electrical system.

Note: Check battery condition weekly or after every 100

hours of operation. Keep terminals and entire battery case

clean because a dirty battery will discharge slowly. To clean

the battery, wash the entire case with solution of baking

soda and water. Rinse with clear water. Coat the battery

posts and cable connectors with Grafo 112X (skin-over)

grease (Toro Part No. 505-47) or petroleum jelly to prevent

corrosion.

Servicing the Fuses

There are 4 fuses in the machines electrical system. They

are located inside control panel (Fig. 63).

Loading...

Loading...