10. Check the uid level and add more uid if the

level is below the threads of the ll-plug hole

( Figure 56 ).

Checking and Adjusting

Neutral

Service Interval : Every 100 hours

When performing routine maintenance and/or engine

diagnostics, the transaxle must be shifted into

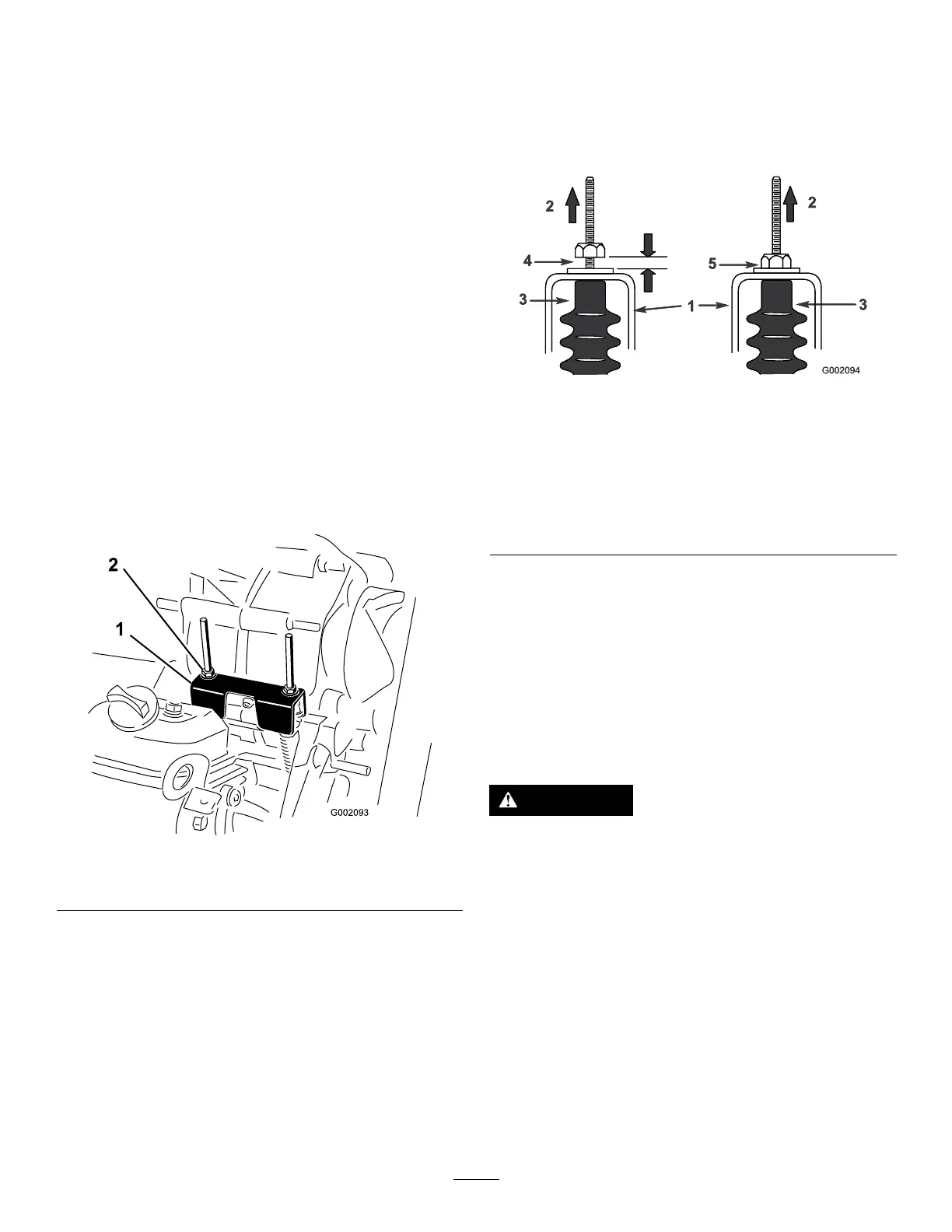

N EUTRAL ( Figure 58 ). The machine has a N EUTRAL

position on the shift lever , which controls the neutral in

the transaxle. Perform the following steps to ensure

that the neutral shift lever operates the transaxle

neutral correctly:

1. Shift the transmission to the N EUTRAL position

2. Ensure that the neutral bracket is in the N EUTRAL

position (level to the cable mounting bracket

located below the shift bracket) by turning the

driven clutch ( Figure 58 ).

Note: The machine should not roll back and

forth. If it does, manually move the neutral

bracket to the N EUTRAL position.

g002093

Figure 58

1. Neutral bracket 2. Locknuts

3. Rotate 1 of the locknuts ( Figure 58 ) to achieve

a 0.762 to 1.524 mm (0.030 to 0.060 inch) gap

between the bottom of the nut/washer and the

neutral bracket.

Note: Y ou must hold the threaded shaft below

the bracket when adjusting the locknut position

on top.

4. Rotate the other locknut to achieve a 0.76

to 1.52 mm (0.03 to 0.06 inch) gap between

the bottom of the nut/washer and the neutral

bracket.

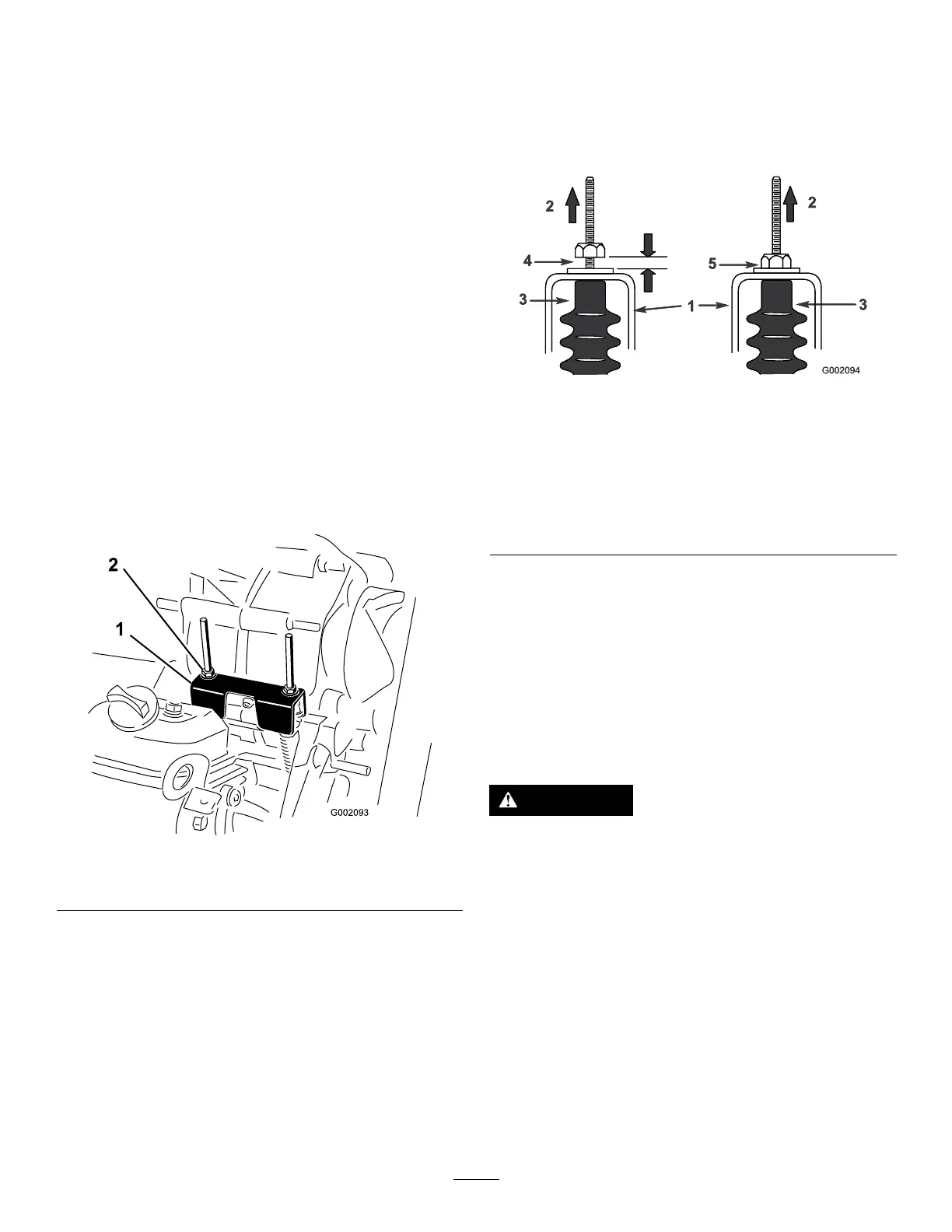

5. Pull up on each shift cable an ensure that there

is a 0.76 to 1.52 mm (0.03 to 0.06 inch) between

the nut/washer and the neutral bracket ( Figure

59 ).

Note: If there is a not a gap, adjust the nuts to

achieve the specied gap.

g002094

Figure 59

1. Neutral bracket

4. 0.76 to 1.52 mm (0.03 to

0.06 inch) gap

2. Pull up 5. W rong —adjust the to

achieve a gap of 0.76 to

1.52 mm (0.03 to 0.06

inch)

3. Cable boot

6. Start the engine and shift into F ORWARD ,

R EVERSE , and N EUTRAL several times to ensure

that the neutral bracket is operating properly .

Maintaining the Primary

Drive Clutch

Service Interval : Every 400 hours/Y early (whichever

comes rst)

CAUTION

The dust in the clutch will become airborne

and could damage your eyes or you could

inhale it, causing breathing difculties.

W ear safety goggles and a dust mask or

other eye and respiratory protection when

performing this procedure.

1. Raise and latch the cargo bed.

2. Remove the 3 bolts securing the cover to the

clutch, and remove the cover ( Figure 60 ).

Note: Retain the cover and bolts for installation.

48

Loading...

Loading...