Cooling System

Maintenance

Cooling System Safety

• Swallowing engine coolant can cause poisoning;

keep out of reach from children and pets.

• Discharge of hot, pressurized coolant or touching

a hot radiator and surrounding parts can cause

severe burns.

– Always allow the engine to cool at least 15

minutes before removing the radiator cap.

– Use a rag when opening the radiator cap, and

open the cap slowly to allow steam to escape.

• Do not operate the machine without the covers

in place.

• Keep your ngers, hands and clothing clear of

rotating fan and drive belt.

• Shut of f the engine and remove the key before

performing maintenance.

Cleaning the

Engine-Cooling Areas

Service Interval : Every 100 hours Clean the cooling

system twice as often during

special operating conditions; refer

to Maintaining the Machine under

Special Operating Conditions ( page

28 ) .

Important: Operating the engine with a blocked

rotating screen, dirty or plugged cooling ns, or

with the cooling shrouds removed, causes engine

damage due to overheating.

Important: Never clean the engine with a pressure

washer because water could contaminate the fuel

system.

Clean the rotating screen, cooling ns, and external

surfaces of the engine.

Note: Clean the engine cooling components more

often under extremely dusty and dirty conditions.

Brake Maintenance

Inspecting the Brakes

Service Interval : Every 100 hours

Important: Brakes are a critical safety component

of the machine. Closely inspect them at the

recommended service interval to ensure optimum

performance and safety .

• Inspect the brake lining for wear or damage. If the

lining (brake pad) thickness is less than 1.6 mm

(1/16 inch), replace the brake lining.

• Inspect the backing plate and other components

for signs of excessive wear or deformation.

Replace any deformed components.

• Check the brake-uid level; refer to Checking the

Brake-Fluid Level ( page 52 ) .

Adjusting the

Parking-Brake Handle

Service Interval : Every 200 hours

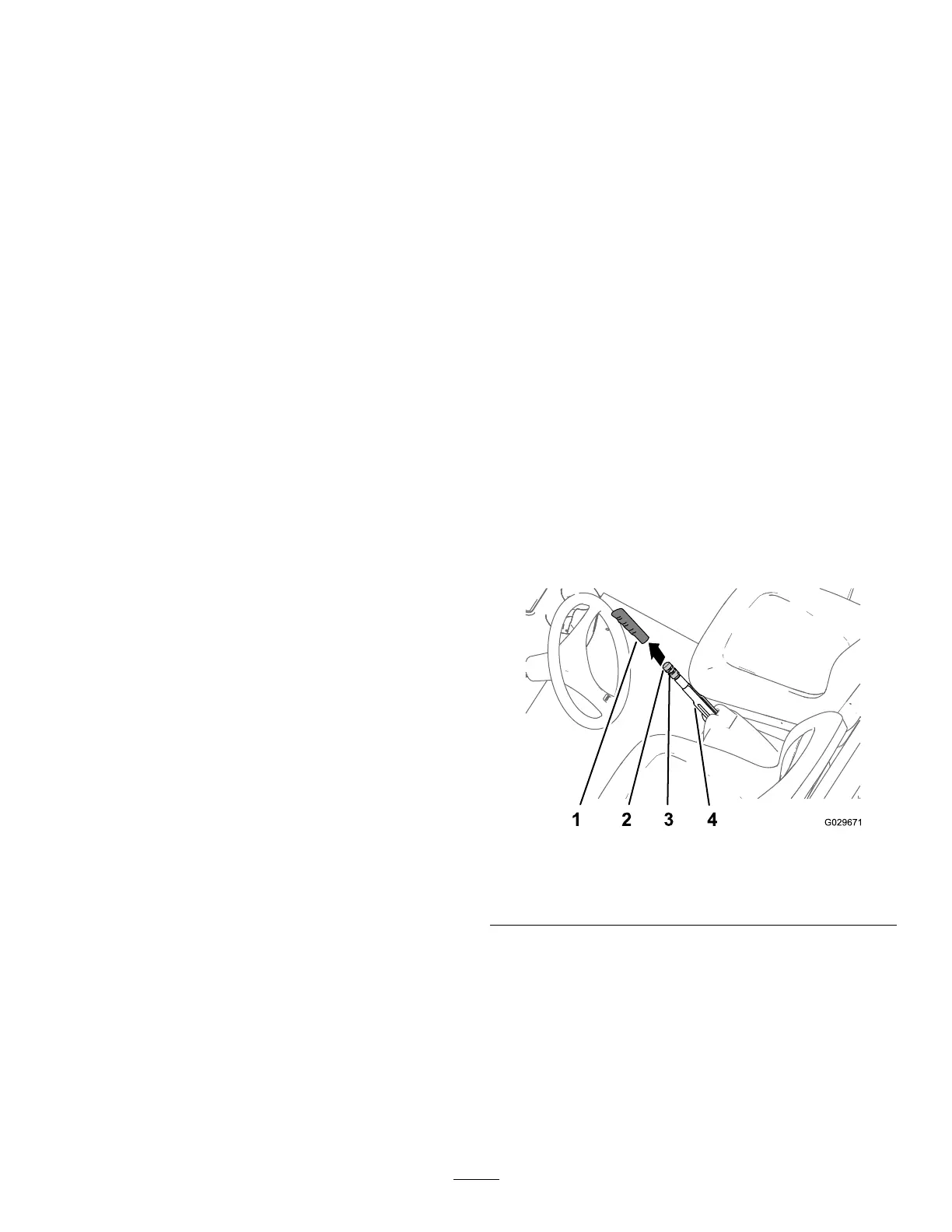

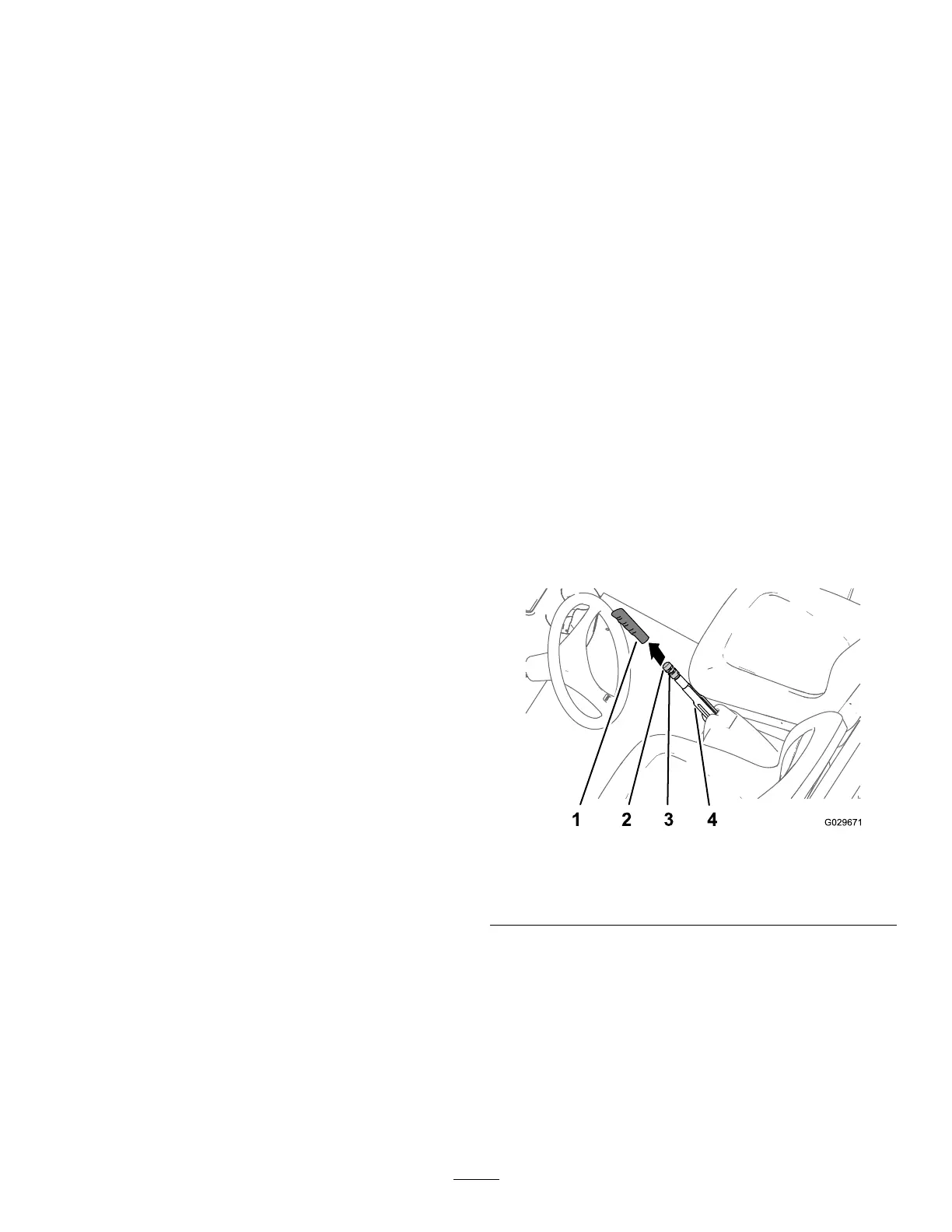

1. Remove the handgrip from the parking-brake

lever ( Figure 62 ).

g029671

Figure 62

1. Handgrip

3. Set screw

2. Brake-adjustment knob 4. Parking-brake lever

2. Loosen the set screw securing the

brake-adjustment knob to the parking-brake

lever ( Figure 62 ).

3. Rotate the brake-adjustment knob until you

reach a force of 133 to 156 N (30 to 35 lbf) to

engage the parking-brake lever ( Figure 62 ).

Note: If you rotated the brake-adjustment knob

the full travel of the adjuster , and cannot attain

the force of 133 to 156 N (30 to 35 lbf) required

to engage the parking-brake lever , perform the

50

Loading...

Loading...