Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Maintenance Safety

• Do not allow untrained personnel to service the

machine.

• Before you leave the operating position, do the

following:

– Park the machine on a level surface.

– Shift the transmission to the N EUTRAL position.

– Engage the parking brake.

– Shut of f the machine and remove the key .

– W ait for all movement to stop.

• Allow the machine to cool before adjusting,

servicing, cleaning, or storing it.

• Support the machine with jack stands whenever

you work under the machine.

• Do not work under a raised bed without the proper

bed safety support in place.

• Do not charge the batteries while servicing the

machine.

• T o ensure that the entire machine is in good

condition, keep all hardware properly tightened.

• T o reduce the potential re hazard, keep the

machine area free of excessive grease, grass,

leaves, and accumulation of dirt.

• If possible, do not perform maintenance while the

machine is running. Keep away from moving parts.

• If you must run the machine to perform a

maintenance adjustment, keep your hands, feet,

clothing, and any parts of the body away from

any moving parts. Keep bystanders away from

the machine.

• Clean up oil and fuel spills.

• Check the parking brake operation as

recommended in the maintenance schedule and

adjust and service it as required.

• Keep all parts of the machine in good working

condition and all the hardware properly tightened.

Replace all worn or damaged decals.

• Never interfere with the intended function of a

safety device or reduce the protection provided

by a safety device.

• Do not overspeed the engine by changing the

governor settings. T o ensure safety and accuracy ,

have an Authorized Service Dealer check the

maximum engine speed with a tachometer .

• If major repairs are ever necessary or assistance

is required, contact an authorized T oro distributor .

• Altering this machine in any manner may af fect the

operation of the machine, performance, durability ,

or its use may result in injury or death. Such use

could void the product warranty of The T oro®

Company .

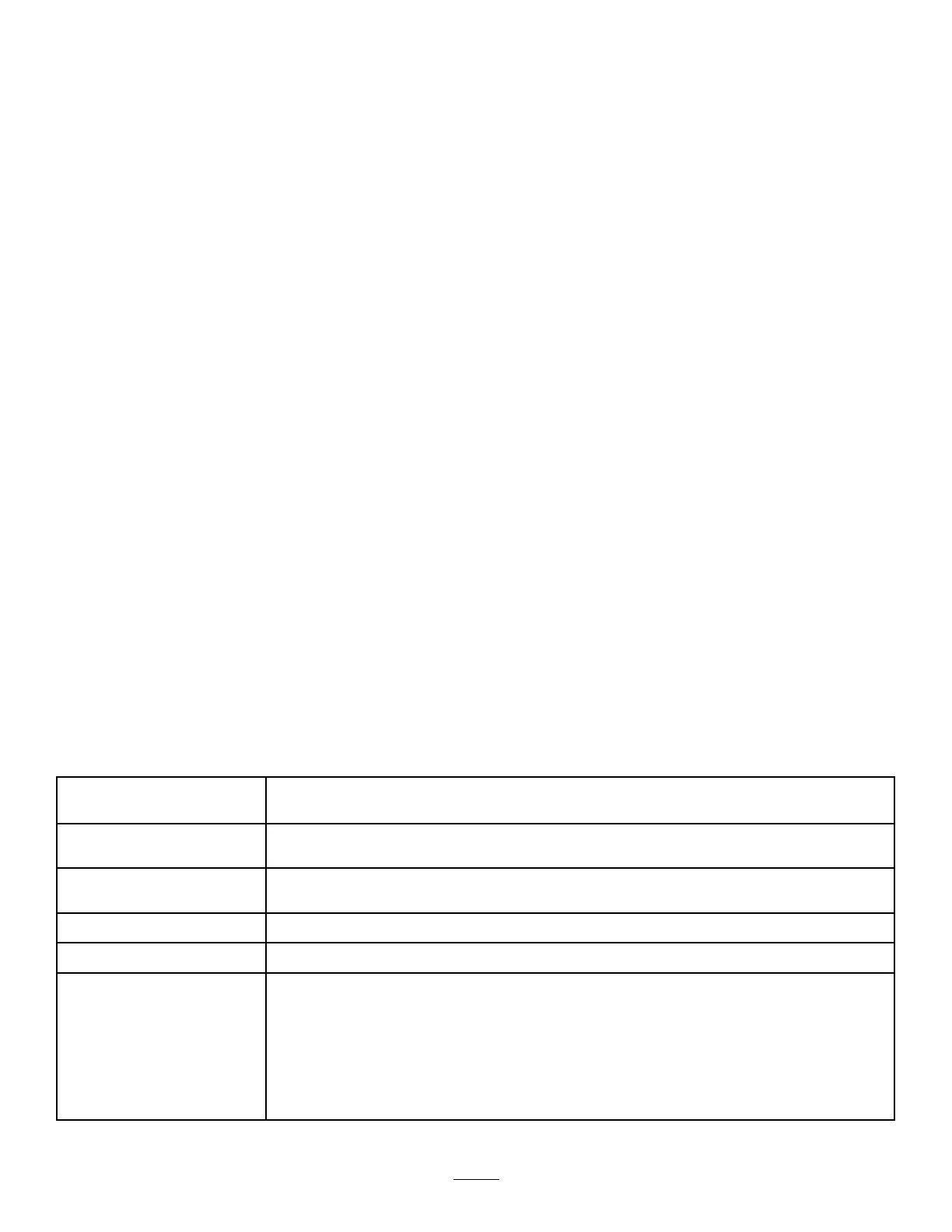

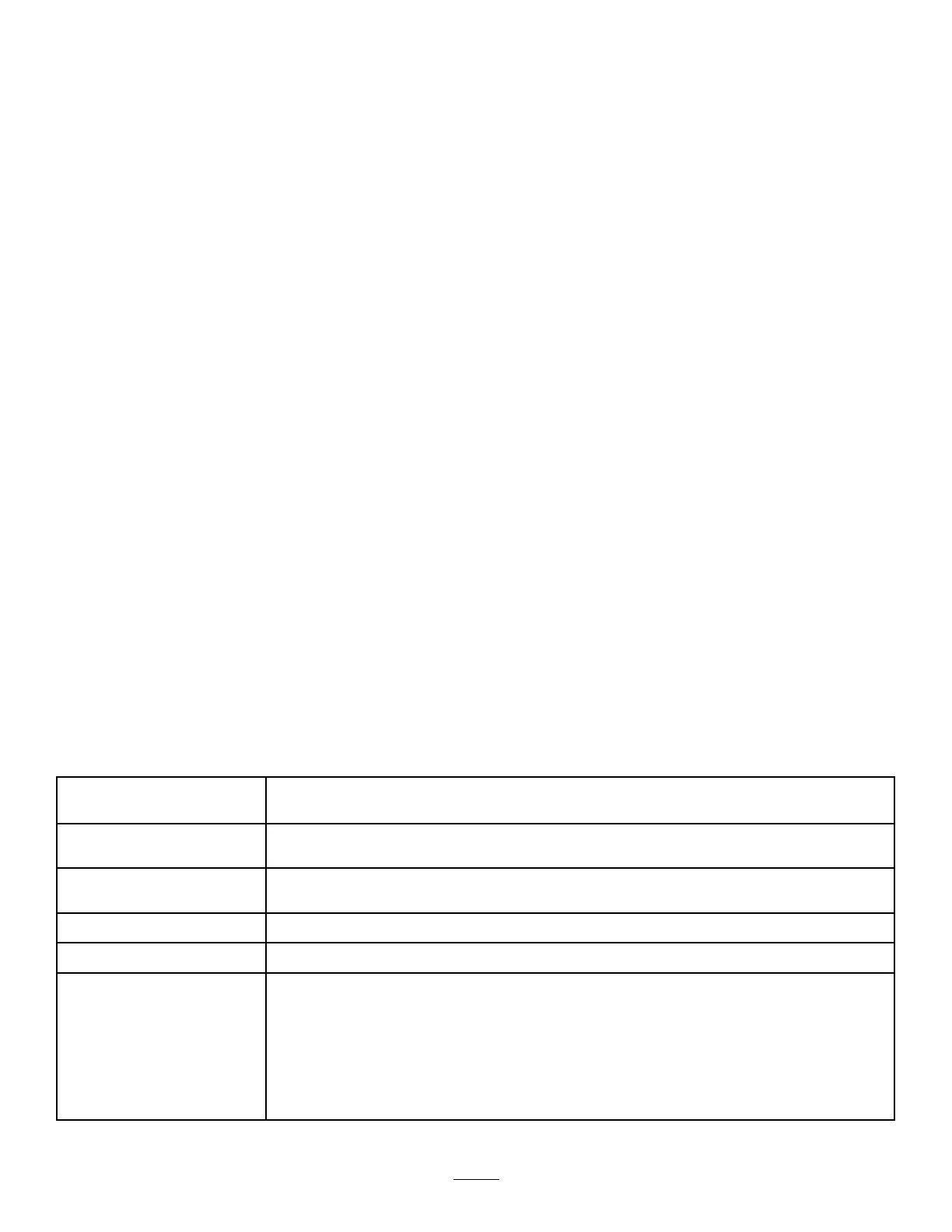

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the rst 8 hours

• Check the condition of the drive belt.

• Check the tension of the starter-generator belt.

After the rst 25 hours

• Change the engine oil.

• Change the engine-oil lter .

After the rst 50 hours

• Adjust the engine-valve clearance.

After the rst 100 hours

• Perform the guidelines for breaking in a new machine.

Before each use or daily

• Inspect the seat belt(s) for wear , cuts, and other damage. Replace the seat belt(s) if

any component does not operate properly .

• Check the tire pressure.

• Check the engine-oil level.

• Check gear-shift operation.

• Check the brake-uid level. Check the brake-uid level before you rst start the

engine.

• W ash the machine.

26

Loading...

Loading...