24

CVHE-SVX02M-EN

Special Lift Requirements

NNOOTTIICCEE

OOiill LLoossss!!

FFaaiilluurree ttoo pprreevveenntt ooiill mmiiggrraattiioonn oouutt ooff tthhee ooiill ttaannkk

ccoouulldd rreessuulltt iinn eeqquuiippmmeenntt ffaaiilluurree oorr pprrooppeerrttyy--oonnllyy

ddaammaaggee..

TToo pprreevveenntt ooiill mmiiggrraattiioonn oouutt ooff tthhee ooiill ttaannkk dduurriinngg

lliiffttiinngg pprroocceedduurreess,, rreemmoovvee tthhee ooiill ffrroomm tthhee ooiill ttaannkk

iiff tthhee uunniitt wwiillll bbee lliifftteedd aatt aannyy aannggllee ggrreeaatteerr tthhaann

1155°° ffrroomm hhoorriizzoonnttaall eenndd--ttoo--eenndd.. IIff ooiill iiss aalllloowweedd ttoo

rruunn oouutt ooff tthhee ooiill ttaannkk iinnttoo ootthheerr aarreeaass ooff tthhee

cchhiilllleerr,, iitt wwiillll bbee eexxttrreemmeellyy ddiiffffiiccuulltt ttoo rreettuurrnn tthhee ooiill

ttoo tthhee ooiill ttaannkk eevveenn dduurriinngg ooppeerraattiioonn..

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

MMoovviinngg tthhee cchhiilllleerr uussiinngg aa ffoorrkk lliifftt ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt oorr pprrooppeerrttyy--oonnllyy ddaammaaggee..

DDoo nnoott uussee aa ffoorrkk lliifftt ttoo mmoovvee tthhee cchhiilllleerr!!

NNOOTTIICCEE

CCoommpprreessssoorr AAlliiggnnmmeenntt!!

FFaaiilluurree ttoo pprreesseerrvvee ccoommpprreessssoorr aalliiggnnmmeenntt ccoouulldd

rreessuulltt iinn eeqquuiippmmeenntt oorr pprrooppeerrttyy--oonnllyy ddaammaaggee..

LLiiffttiinngg tthhee ccoommpprreessssoorr//mmoottoorr aasssseemmbbllyy ffrroomm tthhee

sshheellllss wwiitthhoouutt ffaaccttoorryy--iinnssttaalllleedd ddoowweelliinngg iinn tthhee

ccoommpprreessssoorr ccaassttiinngg ffllaannggeess ccoouulldd rreessuulltt iinn

mmiissaalliiggnnmmeenntt ooff tthhee ccoommpprreessssoorr ccaassttiinnggss..

If the chiller cannot be moved using a standard chiller

lift, consider the following:

• When job site conditions require rigging of the

chiller at an angle greater than 45° from horizontal

(end-to-end), the unit may require removal of the

compressor. Contact Trane or an agent of Trane

specifically authorized to perform start-up and

warranty of Trane® products regarding the

disassembly and reassembly work. For more

information, refer to “Factory Warranty

Information,” p. 3.

NNoottee:: Disassembly and reassembly work includes

dowel-pinning the compressor and removing

it from the unit. Contact Trane or an agent of

Trane specifically authorized to perform start-

up and warranty of Trane

®

products for

specific rigging instructions. Do NOT attempt

to rotate the chiller onto its side.

• When lifting the chiller is either impractical or

undesirable, attach cables or chains to the jacking

slots shown in Figure 5, p. 23; then push or pull the

unit across a smooth surface. Should the chiller be

on a shipping skid, it is not necessary to remove the

skid from the chiller before moving it into place.

• If removal of the compressor or economizer

assembly is necessary to move the chiller to the

operating location, contact Trane. Also refer to

“Factory Warranty Information,” p. 3.

Unit Isolation

To minimize sound and vibration transmission through

the building structure and to ensure proper weight

distribution over the mounting surface, always install

isolation pads or spring isolators under the chiller feet.

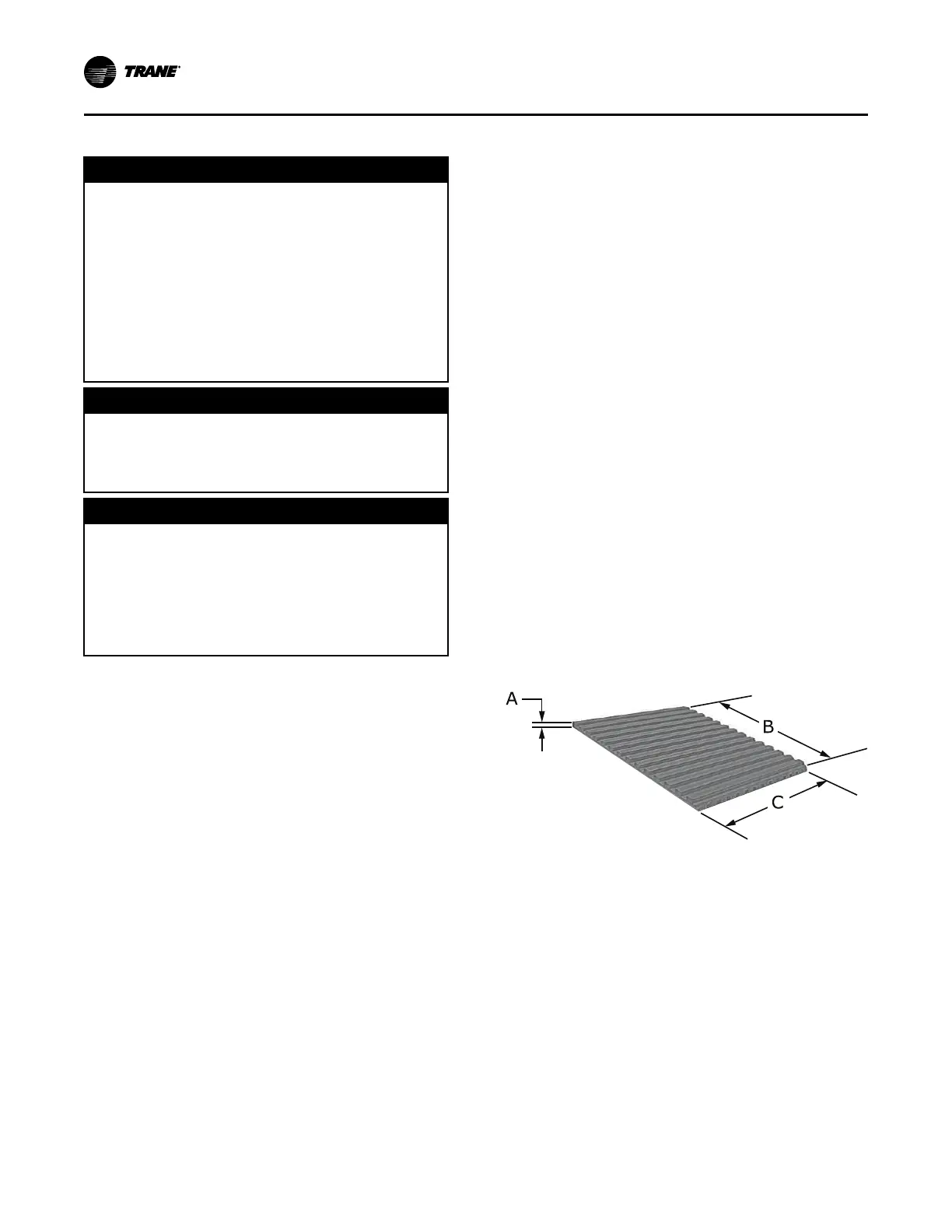

NNoottee:: Isolation pads (refer to Figure 6, p. 24) are

provided with each chiller unless spring isolators

are specified on the sales order.

Specific isolator loading data is provided in the unit

submittal package. If necessary, contact your local

Trane sales office for further information.

IImmppoorrttaanntt:: When determining placement of isolation

pads or spring isolators, remember that the

control panel side of the unit is always

designated as the front side of the unit.

Isolation Pads

When the unit is ready for final placement, position

isolation pads (18-in. [457.2-mm] sides) end for end

under the full length of the chiller leg. The pads

measure 9 in. × 18 in. (228.6 mm x 457.2 mm) and on

some units there may be small gaps between pads.

Pads are provided to cover entire foot. Place pad flush

with the outside edge of the chiller foot and leave

excess material under the chiller.

Figure 6. Isolation pad and dimensions

A = 3/8 in. (9.5 mm)

B = 18 in. (457.2 mm)

C = 9 in. (228.6 mm)

Remember that the chiller must be level within 1/16 in.

(1.6 mm) over its length and width after it is lowered

onto the isolation pads. In addition, all piping

connected to the chiller must be properly isolated and

supported so that it does not place any stress on the

unit.

Spring Isolators

Spring isolators should be considered whenever chiller

installation is planned for an upper story location. Base

isolator placement is shown in the following figure.

IInnssttaallllaattiioonn:: MMeecchhaanniiccaall

Loading...

Loading...