CVHE-SVX02M-EN

57

Power Supply Wiring

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy..

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee//nnaattiioonnaall eelleeccttrriiccaall ccooddeess..

Three-Phase Power

Review and follow the guidelines in this section to

properly install and connect the power supply wiring to

the starter panel:

• Verify that the starter nameplate ratings are

compatible with the power supply characteristics

and with the electrical data on the unit nameplate.

NNOOTTIICCEE

AAddaappttiivvee FFrreeqquueennccyy DDrriivvee ((AAFFDD))//

SSttaarrtteerr CCoommppoonneenntt DDaammaaggee!!

FFaaiilluurree ttoo rreemmoovvee ddeebbrriiss ffrroomm iinnssiiddee tthhee AAFFDD//

ssttaarrtteerr ppaanneell ccoouulldd rreessuulltt iinn aann eelleeccttrriiccaall sshhoorrtt aanndd

ccoouulldd ccaauussee sseerriioouuss AAFFDD//ssttaarrtteerr ccoommppoonneenntt

ddaammaaggee..

NNOOTTIICCEE

UUssee CCooppppeerr CCoonndduuccttoorrss OOnnllyy!!

FFaaiilluurree ttoo uussee ccooppppeerr ccoonndduuccttoorrss ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee aass uunniitt tteerrmmiinnaallss aarree nnoott

ddeessiiggnneedd ttoo aacccceepptt ootthheerr ttyyppeess ooff ccoonndduuccttoorrss..

• Do NOT modify or cut enclosure to provide

electrical access. Removable panels have been

provided and any modification should be done

away from the enclosure. If the starter enclosure

must be cut to provide electrical access, exercise

care to prevent debris from falling inside the

enclosure.

• Use copper conductors to connect the three-phase

power supply to the remote- or unit-mounted

starter panel.

• Flexible conduit connections are recommended to

enhance serviceability and minimize vibration

transmission.

• Size the power supply wiring in accordance with

National Electric Code (NEC), using the RLA value

stamped on the chiller nameplate and transformer

load on L1 and L2.

• Confirm that wire size is compatible with lug size

stated in unit submittal.

• Make sure that the incoming power wiring is

properly phased; each power supply conduit run to

the starter must carry the correct number of

conductors to ensure equal phase representation.

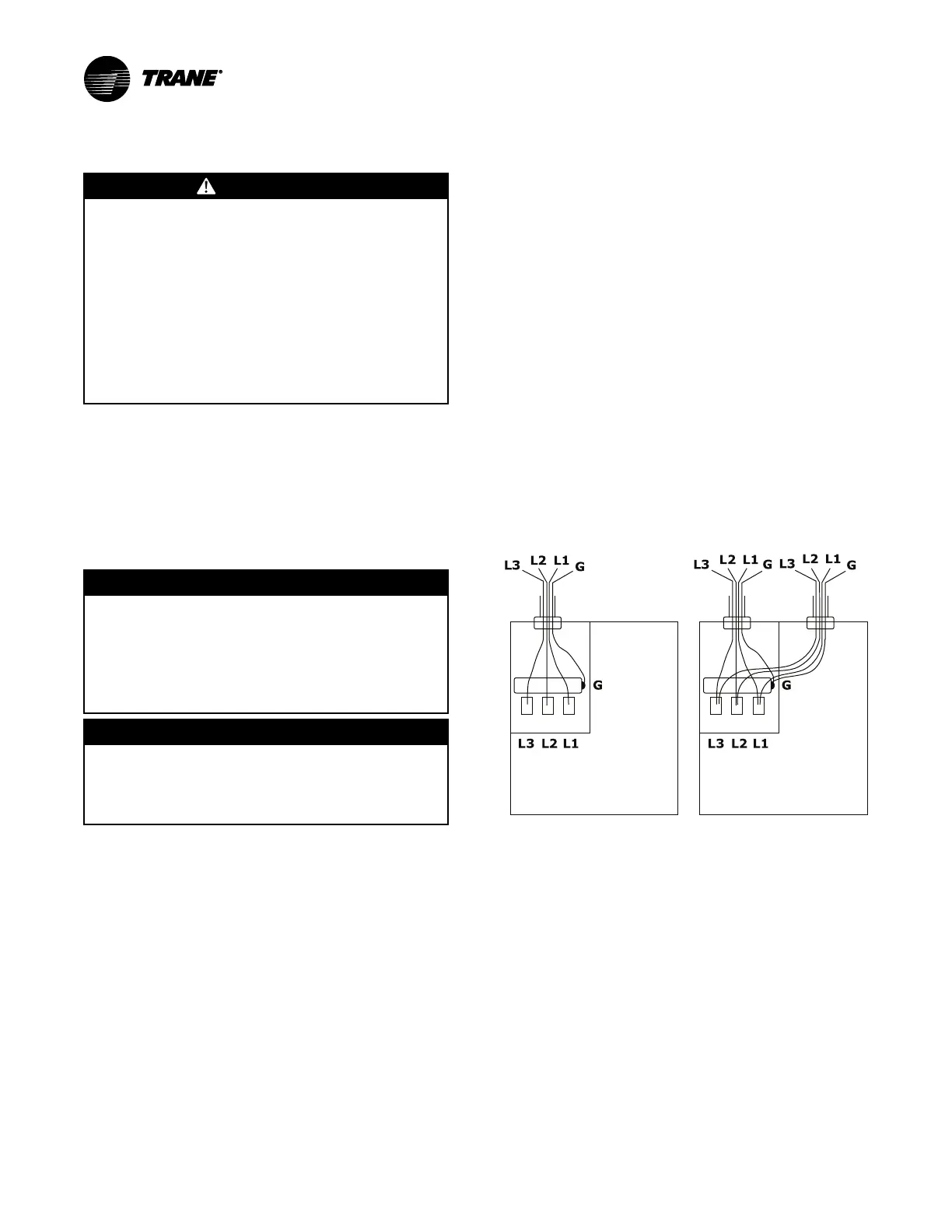

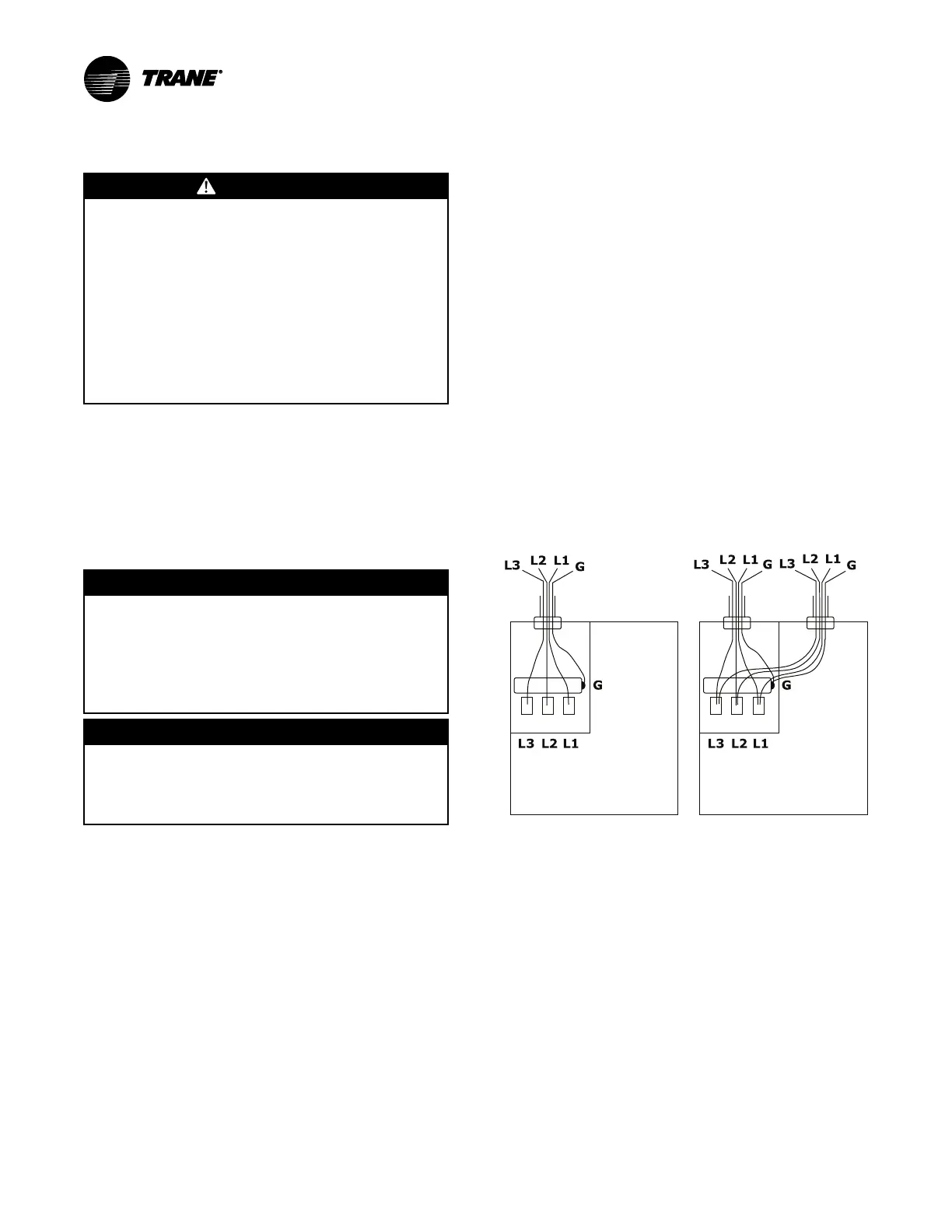

NNoottee:: Connect L1, L2, and L3 (shown in the

following figure) per starter diagram

provided with chiller.

• When installing the power supply conduit, ensure

that the position of the conduit does not interfere

with the serviceability of any of the unit

components, or with structural members and

equipment. Ensure that the conduit is long enough

to simplify any servicing that may be necessary in

the future (e.g., starter).

• Electrical wire torque specifications—follow starter

manufacturer’s torque specifications.

Figure 37. Proper phasing for starter power supply

wiring

Circuit Breakers and Fused

Disconnects

Any field-supplied circuit breaker or fused disconnect

installed in power supplied to the chiller must be sized

in compliance with National Electric Code (NEC) or

local guidelines.

Power Factor Correction

Capacitors (Optional)

Power factor correction capacitors (PFCCs) are

designed to provide power factor correction for the

compressor motor. PFCCs are available as an option

for unit- and remote-mounted starters.

Loading...

Loading...