72

CVHE-SVX02M-EN

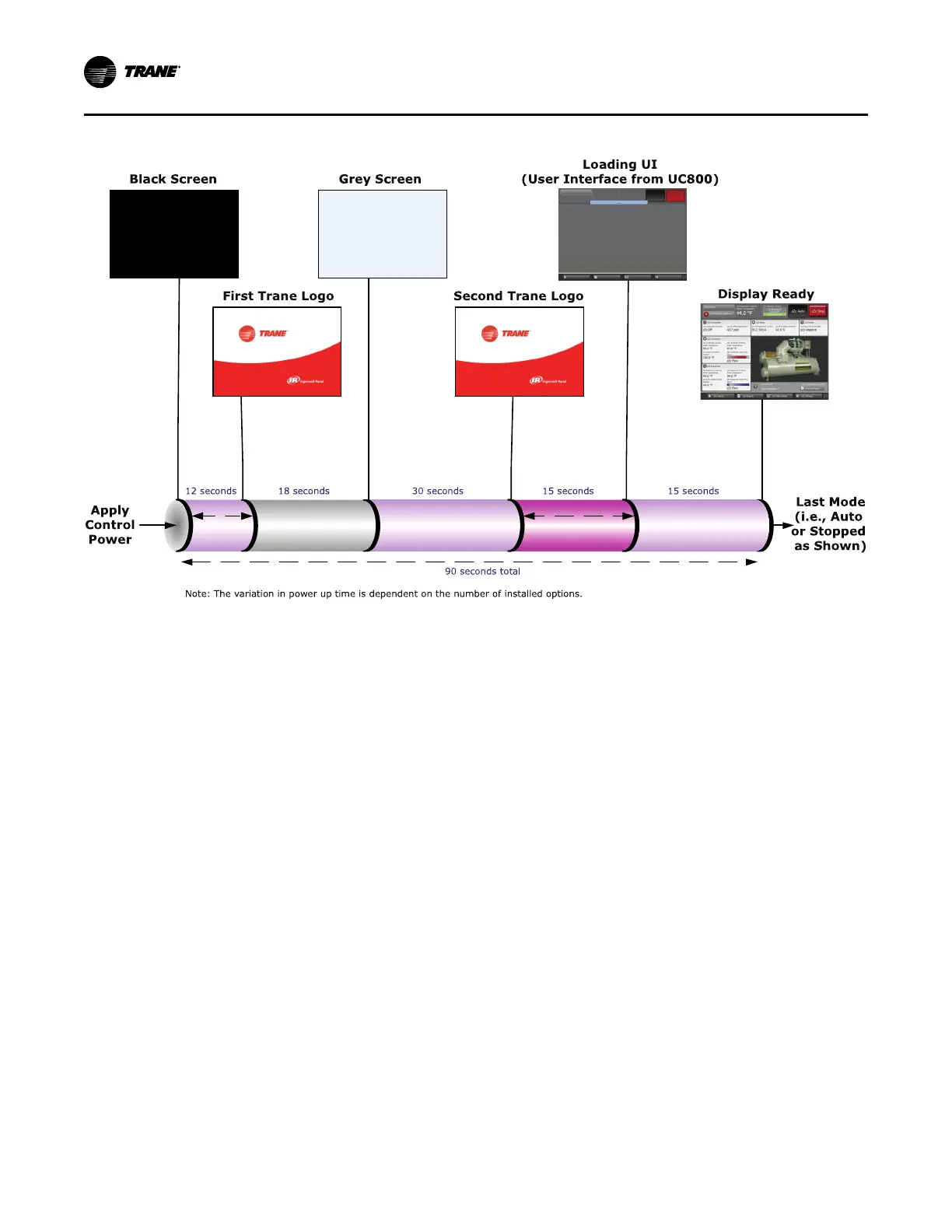

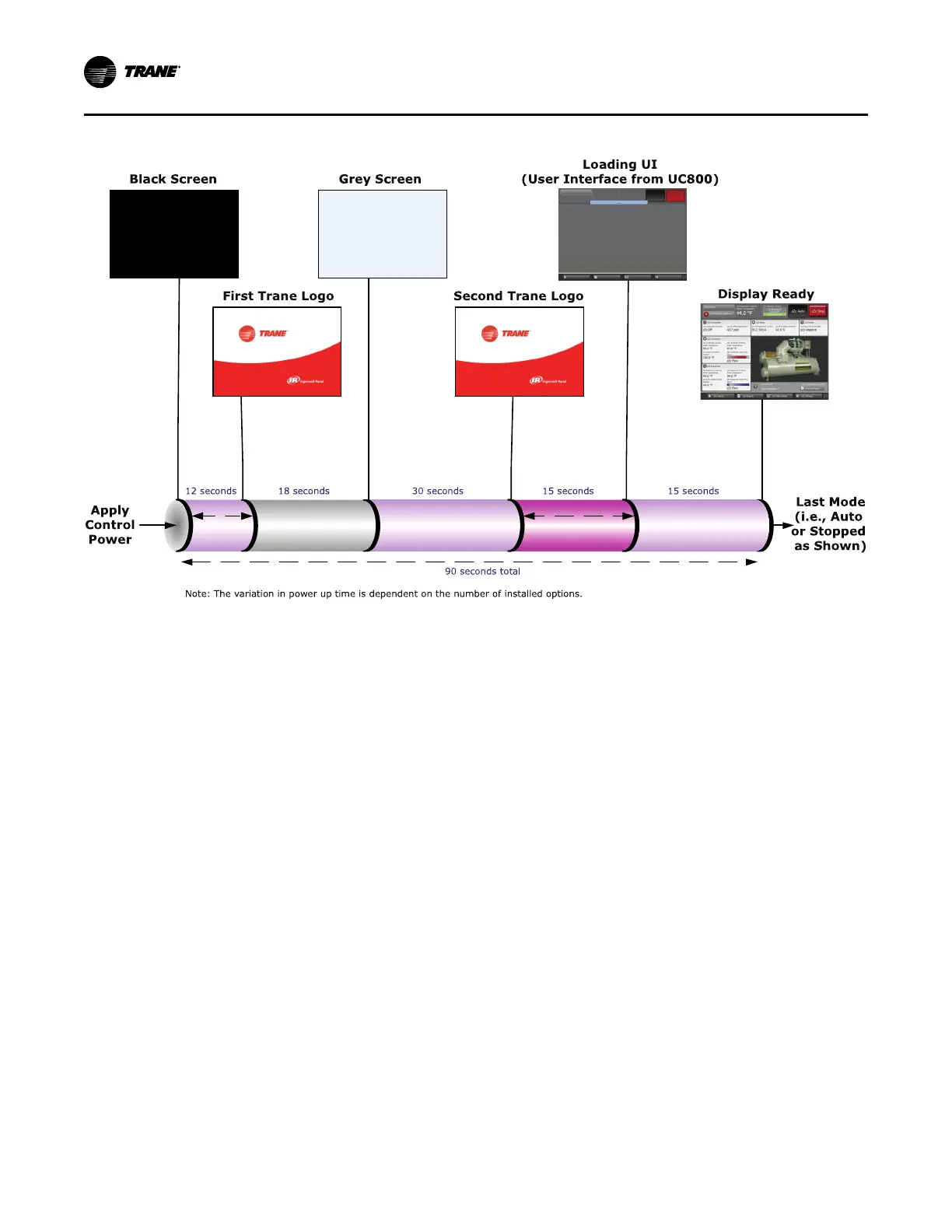

Figure 50. Sequence of operation: Tracer®® AdaptiView™™ power up

In the following diagrams:

• The time line indicates the upper level operating

mode, as it would be viewed in the Tracer®

AdaptiView™.

• The shading color of the cylinder indicates the

software state.

• Text in parentheses indicates sub-mode text as

viewed in the Tracer® AdaptiView™.

• Text above the time line cylinder is used to illustrate

inputs to the UC800. This may include user input to

the Tracer® AdaptiView™ touch screen, control

inputs from sensors, or control inputs from a

generic BAS.

• Boxes indicate control actions such as turning on

relays, or moving the inlet guide vanes.

• Smaller cylinders indicate diagnostic checks, text

indicates time-based functions, solid double arrows

indicate fixed timers, and dashed double arrows

indicate variable timers.

Start-up Sequence of Operation—Wye-

delta

Logic circuits within the various modules will

determine the starting, running, and stopping

operation of the chiller. When operation of the chiller is

required, the chiller mode is set at “Auto.” Using

customer-supplied power, the chilled water pump relay

is energized and chilled water flow must be verified

within 4 minutes and 15 seconds. The UC800 decides to

start the chiller based on the differential to start

setpoint. With the differential to start criteria met, the

UC800 then energizes condenser water pump relay

with customer-supplied power (refer to Figure 51, p.

73).

Based on the Restart Inhibit function and the

Differential to Start setpoint, the oil and refrigerant

pump is energized. The oil pressure must be at least

12 psid (82.7 kPaD) for 60 continuous seconds and

condenser water flow verified within 4 minutes and

15 seconds for the compressor start sequence to be

initiated.

The compressor motor starts in the “Wye”

configuration and then, after the compressor motor has

accelerated and the maximum phase current has

dropped below 85 percent of the chiller nameplate RLA

for 1.5 seconds, the starter transitions to the “Delta”

configuration.

SSttaarrtt--uupp aanndd SShhuutt--ddoowwnn

Loading...

Loading...