60

CVHE-SVX02M-EN

Terminal Clamps

NNOOTTIICCEE

UUssee CCooppppeerr CCoonndduuccttoorrss OOnnllyy!!

FFaaiilluurree ttoo uussee ccooppppeerr ccoonndduuccttoorrss ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee aass uunniitt tteerrmmiinnaallss aarree nnoott

ddeessiiggnneedd ttoo aacccceepptt ootthheerr ttyyppeess ooff ccoonndduuccttoorrss..

Terminal clamps are supplied with the motor terminals

to accommodate either bus bars or standard motor

terminal wire lugs. Terminal clamps provide additional

surface area to minimize the possibility of improper

electrical connections.

Wire Terminal Lugs

NNOOTTIICCEE

CCoommppoonneenntt DDaammaaggee!!

FFaaiilluurree ttoo eennssuurree tthhee ppoowweerr ssuuppppllyy wwiirriinngg aanndd

oouuttppuutt ttoo mmoottoorr wwiirriinngg aarree ccoonnnneecctteedd ttoo tthhee

pprrooppeerr tteerrmmiinnaallss ccoouulldd ccaauussee ccaattaassttrroopphhiicc ffaaiilluurree

ooff tthhee ssttaarrtteerr aanndd//oorr mmoottoorr..

Wire terminal lugs must be field supplied.

• Use field-provided, crimp-type wire terminal lugs

properly sized for the application.

NNoottee:: Wire size ranges for the starter line and load-

side lugs are listed on the starter submittal

drawings supplied by the starter

manufacturer or Trane. Carefully review the

submitted wire lug sizes for compatibility

with the conductor sizes specified by the

electrical engineer or contractor.

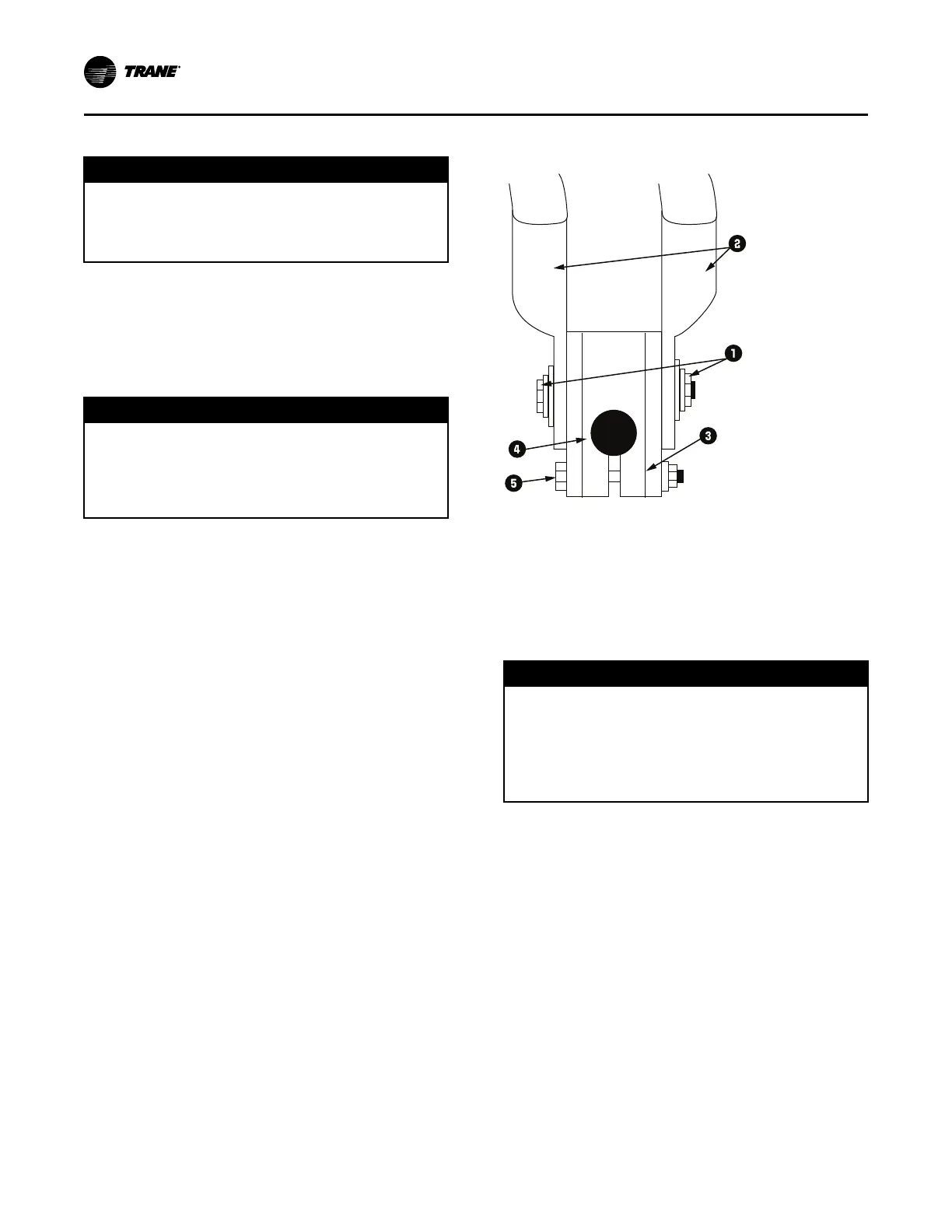

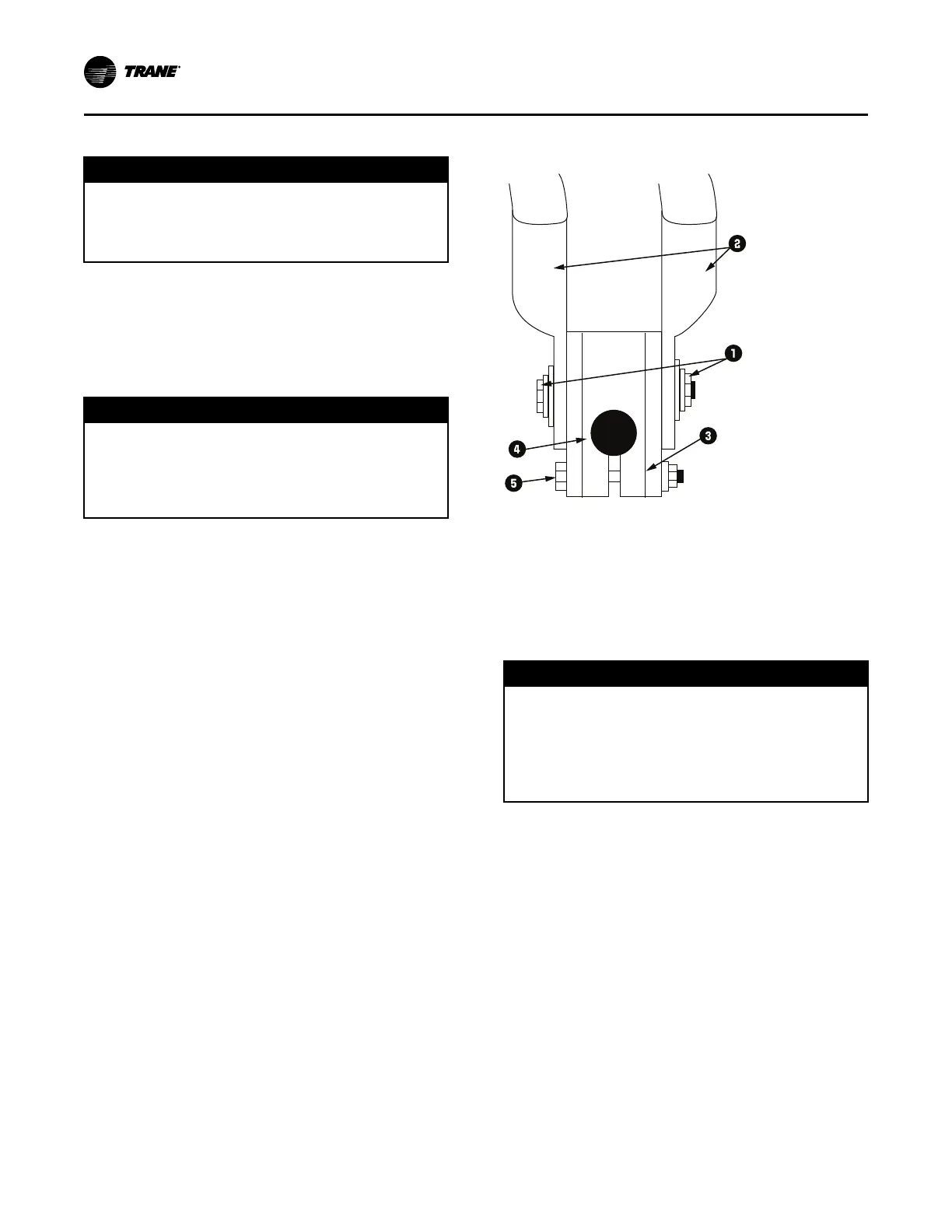

• On 4160V and below, a terminal clamp with a

3/8-in. (9.525-mm) bolt is provided on each motor

terminal stud; use the factory-supplied Belleville

washers on the wire lug connections. The following

figure illustrates the junction between a motor

terminal stud and terminal lug.

• Torque for this assembly is 24 ft·lb (32.5 N·m).

• Install but do NOT connect the power leads

between the starter and compressor motor. (These

connections will be completed under supervision of

a qualified Trane service engineer after the pre-start

inspection.)

Figure 42. Terminal stud, clamp, and lug assembly

(4160V and below)

1. Belleville washer

2. Terminal lugs

3. Terminal clamp

4. Motor terminal stud

5. 3/8-in. bolt

Bus Bars

NNOOTTIICCEE

CCoommppoonneenntt DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd ccaauussee aann

eelleeccttrriiccaall sshhoorrtt wwhhiicchh ccoouulldd rreessuulltt iinn ccoommppoonneenntt

ddaammaaggee..

RReemmoovvee ddeebbrriiss ffrroomm iinnssiiddee tthhee CCPPTTRR ooppttiioonn

eenncclloossuurree ppaanneell bbeeffoorree ttuurrnniinngg tthhee ppoowweerr oonn..

Bus bars and extra nuts are available as a Trane option.

Install the bus bars between the motor terminals when

using a starter that is:

• A low-voltage Adaptive Frequency™ Drive (AFD)

• Across-the-line

• Primary reactor/resistor

• Autotransformer

• Customer-supplied

Connect T1 to T6, T2 to T4, and T3 to T5.

NNoottee:: Bus bars are not needed in medium-voltage or

high-voltage applications since only

three terminals are used in the motor and starter.

When attaching starter leads to 6.6 to 7kV motor

terminals, the 1/2-in.-13 brass jam nuts should be

tightened to a maximum torque of 18 to 22 ft·lb (24.4 to

29.8 N·m). Always use a second wrench to backup the

PPoowweerr SSuuppppllyy WWiirriinngg

Loading...

Loading...