Group 21 Service procedures - engine

29

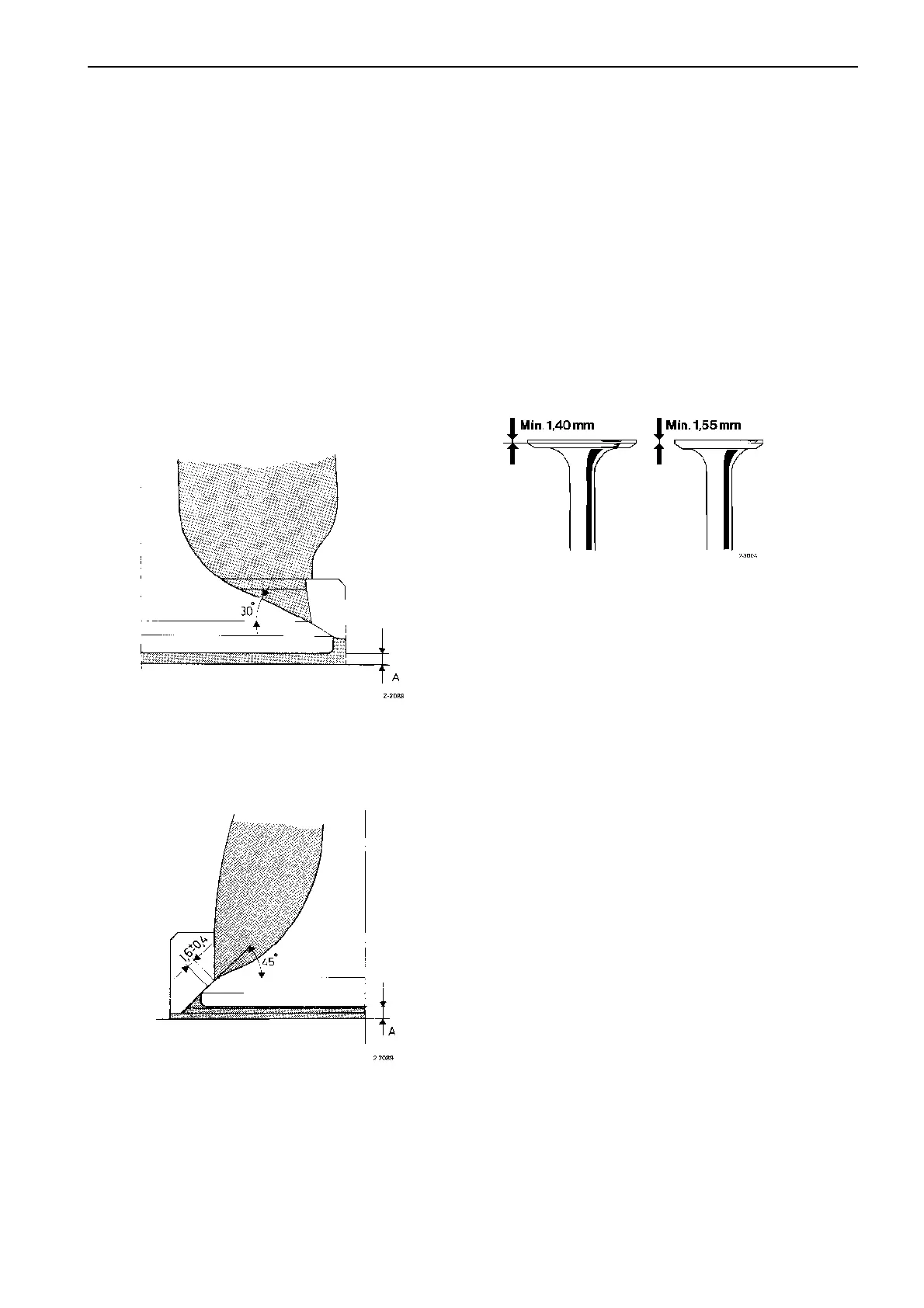

Valve seats, grinding

Before grinding, check the valve guides and replace them if

the wear limits have been exceeded.

Grind the valve seat just enough to give correct form and an-

gle and to ensure good contact.

The seat should be replaced when distance ”A”, measured

with a new valve, exceeds 1.0 mm (0.0394”).

A new seat is ground until the measurement between the

cylinder head face and the upper area of the valve (A) is 0.0-

0.4 mm (0.0-0.0158") for both inlet and exhaust valves.

This angle is checked with a valve seat gauge after coating

the seat contact surface with a light layer of marking paint.

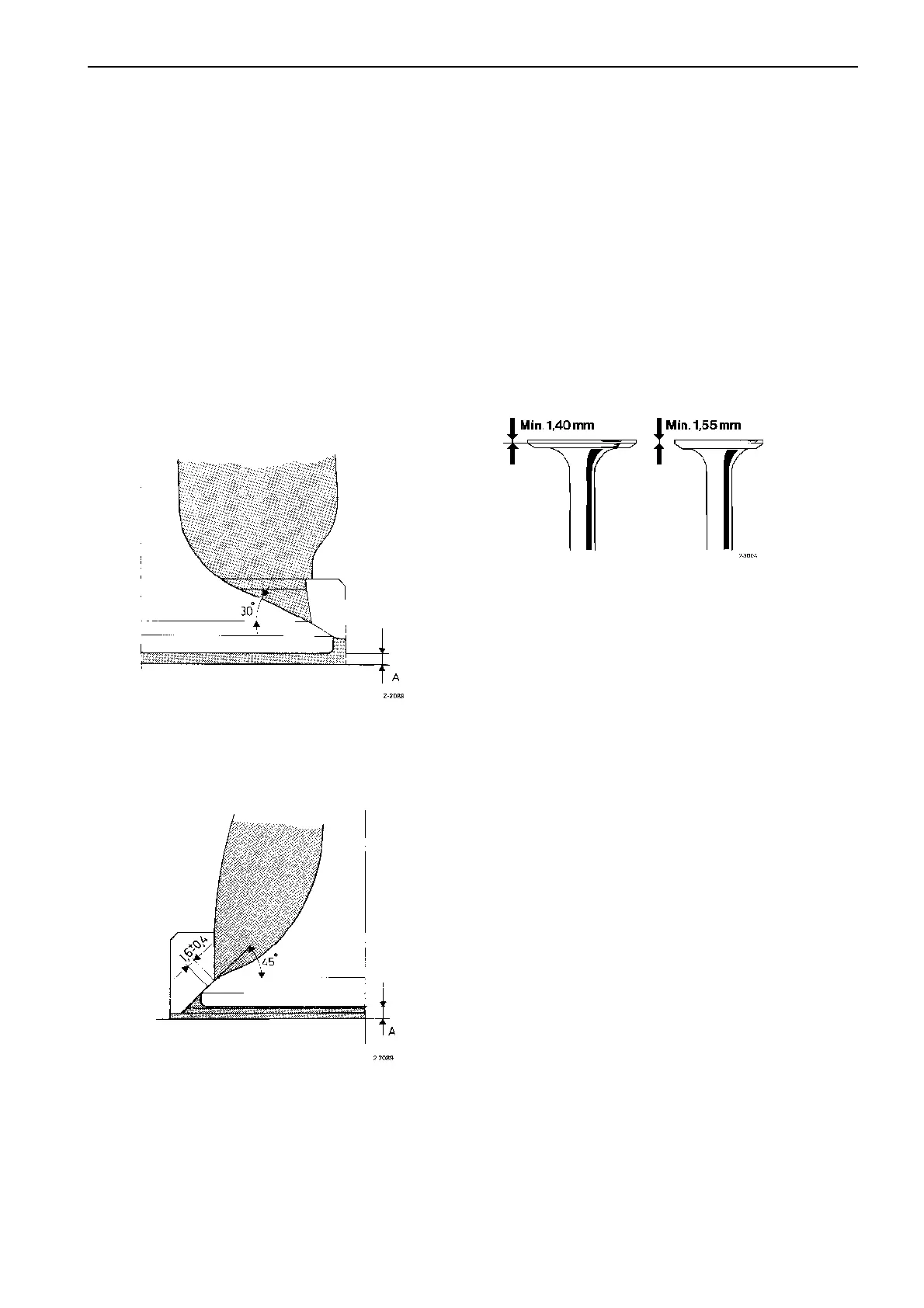

Valves, grinding

Valve sealing angles:

Inlet 29,5°

Exhaust 44,5°

The sealing surface should be ground as little as possible,

just enough to remove all signs of damage.

If there is an edge of less than 1.40 mm (0.0552")on inlet

valves and 1.55 mm (0.0610") on exhaust valves, the valve

must be replaced. This also applies if the valve stem is bent.

Intake valve

Check for leakage using marking paint.

If leakage is found, regrind the valve seat - not the valve -

and recheck for leakage.

Exhaust valve

Loading...

Loading...