Service procedures - engine Group 21

34

Valves, adjusting

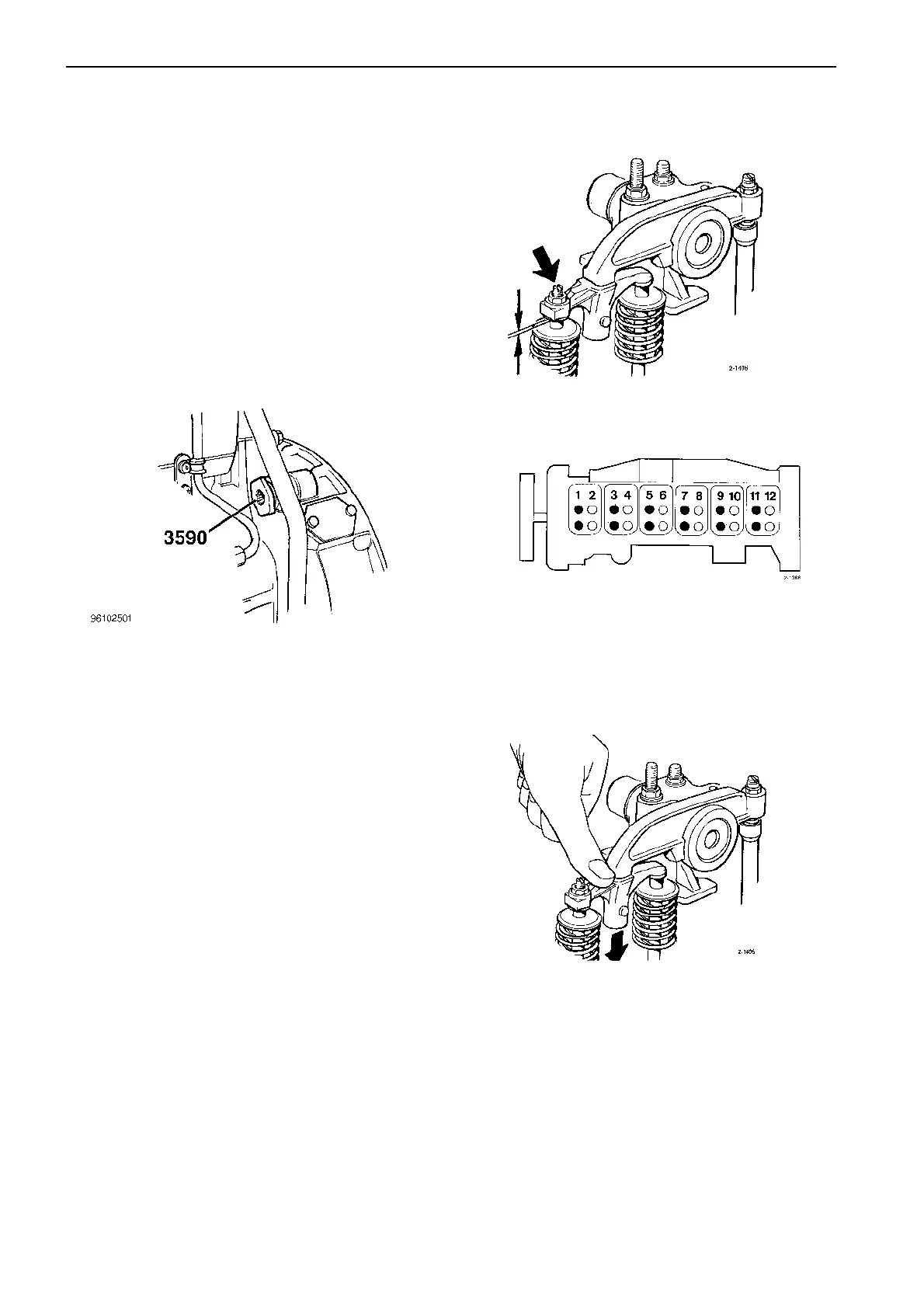

Special tools: 998,3590

Valves are adjusted with the engine cold. On no condition

should the engine be running since the valves can strike

against the piston and cause serious damage.

Make sure that the stop control is pulled out and the starting

key is turned off.

Valve adjustments are done in accordance with the two-po-

sition method, but also each pair of valves are adjusted in

two stages. The first stage is to adjust the valve caliper, the

second to adjust the rocker arm play.

1

Remove the plug in the flywheel casing and attach crank-

ing tool 998 3590.

2

Remove the delivery pipe and the fuel return pipe.

3

Remove all valve covers.

Note: After removing the valve cover, always check the

torque on the studbolt to the rocker arm bridge. Correct

torque 48 Nm (35.4 ft-lb).

4

Crank the flywheel in the engine’s direction of rotation until

1st piston is in the top dead center after the compression

stroke (0° on the flywheel, both pairs of valves on 6th cylin-

der rocking).

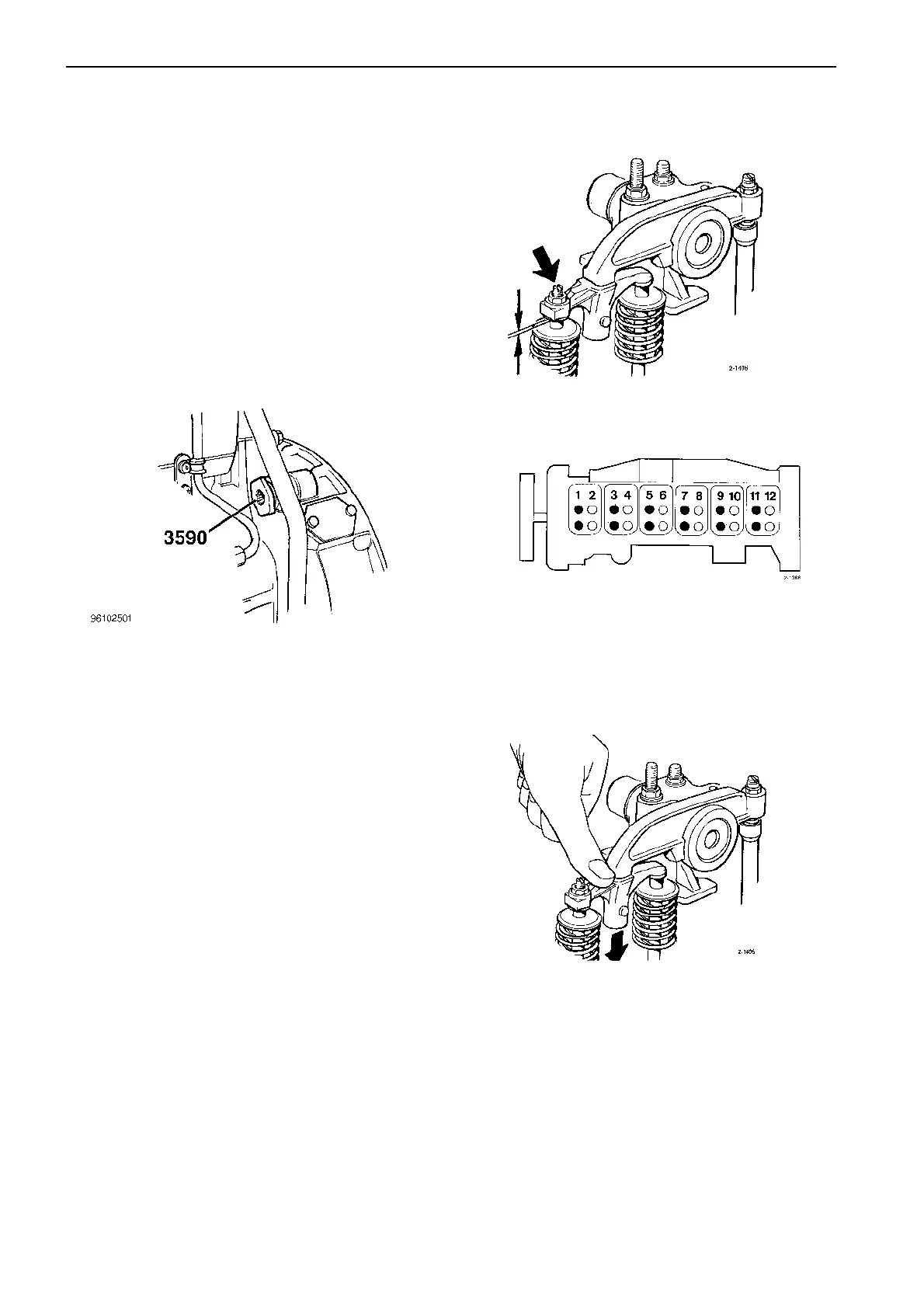

Adjusting the valve caliper

5

Slacken the lock nut and adjusting screw for the no. 1 pair

of valves on 1st cylinder until there is play between the

caliper and the valve stem.

6

Press the valve caliper down.

7

Turn the adjusting screw until it touches the valve stem.

Loading...

Loading...