Manual Manual 37223E 37223E easYgen-3000 easYgen-3000 Series Series (Package (Package P1) P1) - - Genset Genset ControlControl

© © Woodward Woodward Page Page 15/6715/67

Screw Kit InstallationScrew Kit Installation

NOTE

NOTE

Don't drill the holes if you want to use Don't drill the holes if you want to use the clamp fasteners. If the the clamp fasteners. If the holes are drilled into the panel, theholes are drilled into the panel, the

clamp fasteners cannot be used anymore!clamp fasteners cannot be used anymore!

NOTE

NOTE

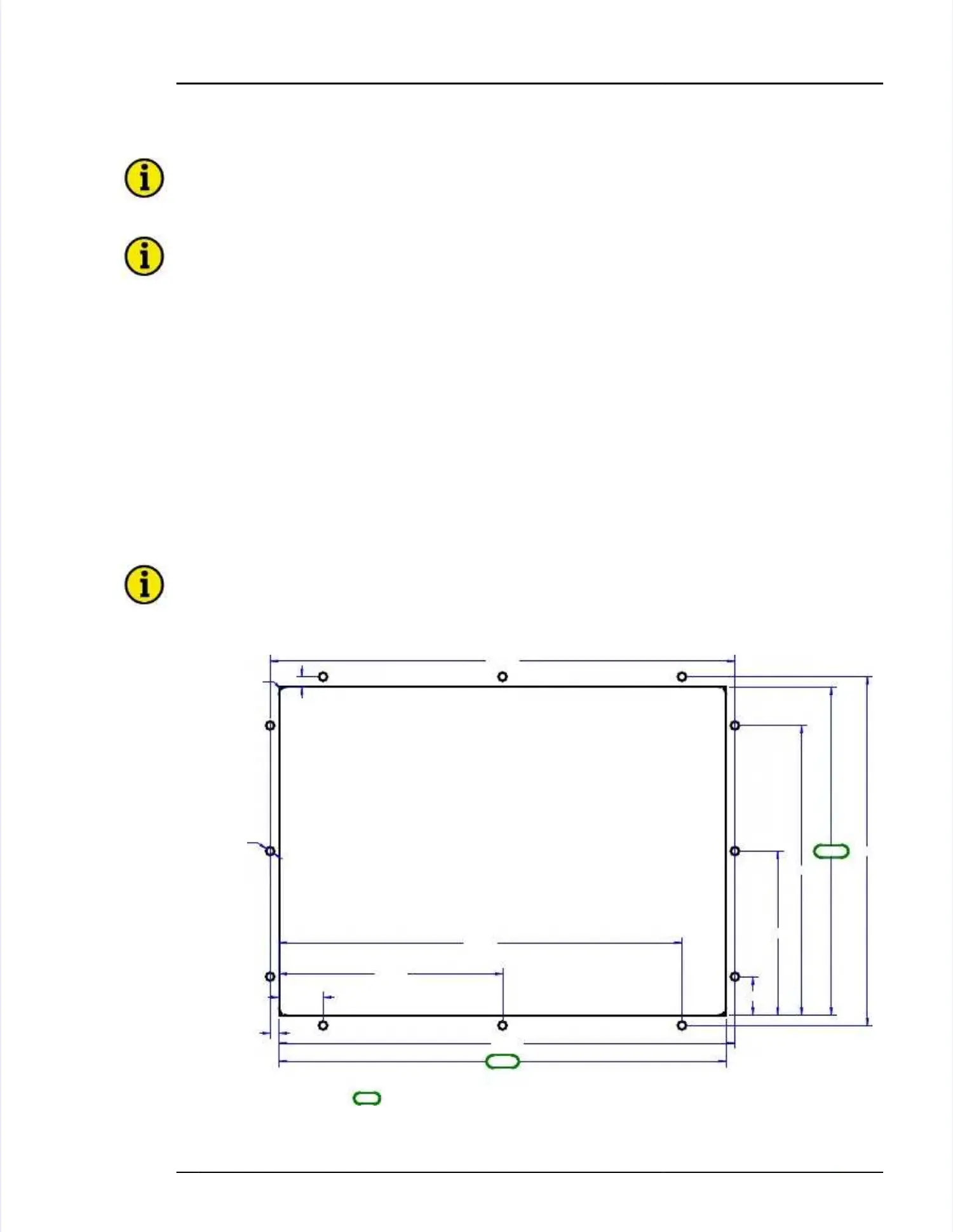

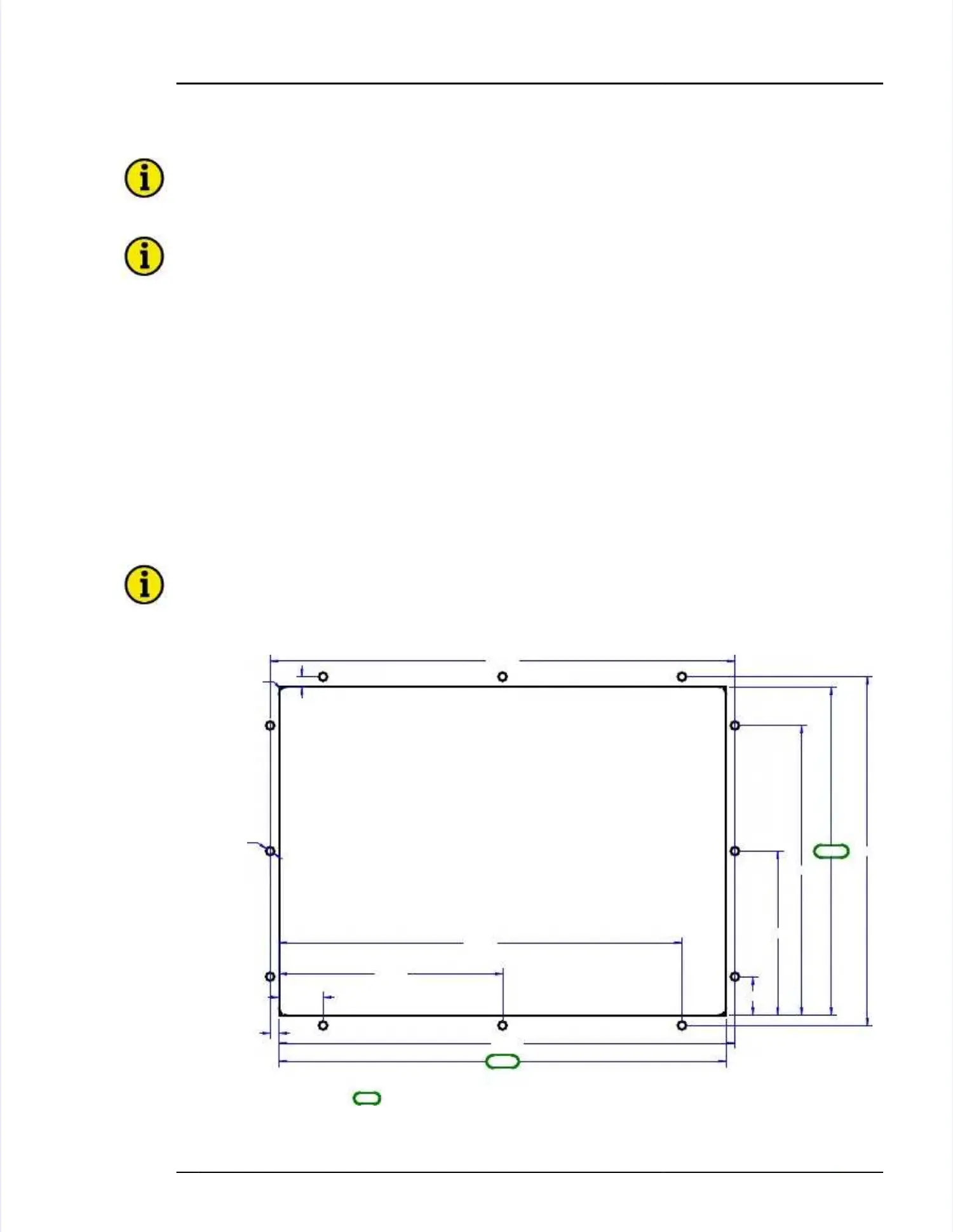

The housing is equipped with 12 nut The housing is equipped with 12 nut inserts (refer toinserts (refer toFigure 4-5Figure 4-5 for their position), which must all befor their position), which must all be

tightened properly to achieve the required degree of protection.tightened properly to achieve the required degree of protection.

Some versions of the plastic housing are not equipped wSome versions of the plastic housing are not equipped with nut inserts and may not be fastened with nut inserts and may not be fastened withith

the screw kit.the screw kit.

In order to enhance the protection to IP 66, it is possible to fasten the unit with a screw kit instead of the clampIn order to enhance the protection to IP 66, it is possible to fasten the unit with a screw kit instead of the clamp

fastener hardware.fastener hardware.

Proceed as follows to install Proceed as follows to install the unit using the screw kit:the unit using the screw kit:

1.1. Cut out the panel and drill Cut out the panel and drill the holes according to the dimensions inthe holes according to the dimensions inFigure 4-5Figure 4-5 (dimensions shown in mm).(dimensions shown in mm).

2.2. Insert the unit into the panel cutout. Verify that the unit fits correctly in the cutout. If the panel cutout is notInsert the unit into the panel cutout. Verify that the unit fits correctly in the cutout. If the panel cutout is not

big enough, enlarge it accordingly.big enough, enlarge it accordingly.

3.3.

Insert the screws and tighten to 0.6 Insert the screws and tighten to 0.6 Nm (5.3 pound inches) of tNm (5.3 pound inches) of torque. Tighten the screws with a crosswiseorque. Tighten the screws with a crosswise

pattern to ensure even pressure distribution.pattern to ensure even pressure distribution.

NOTE

NOTE

If the thickness of the panel sheet exceeds 2.5 mm, be sure to use screws with a length of the panelIf the thickness of the panel sheet exceeds 2.5 mm, be sure to use screws with a length of the panel

sheet thickness + 4 mm.sheet thickness + 4 mm.

Cut-out dimension:

Cut-out dimension:

249mm (+1,1mm) x 183mm (+1,0mm)249mm (+1,1mm) x 183mm (+1,0mm)

249.0249.0

183.0183.0

5.5.00

254.0254.0

24.524.5

124.5124.5

224.5224.5

21.521.5

91.591.5

161.5161.5

194.4194.4

259.0259.0

55.7.7

ø 4.5ø 4.512 12 xx

Rmax:Rmax: R 4.0R 4.0

Figure 4-5: Plastic housing - drill planFigure 4-5: Plastic housing - drill plan

Loading...

Loading...