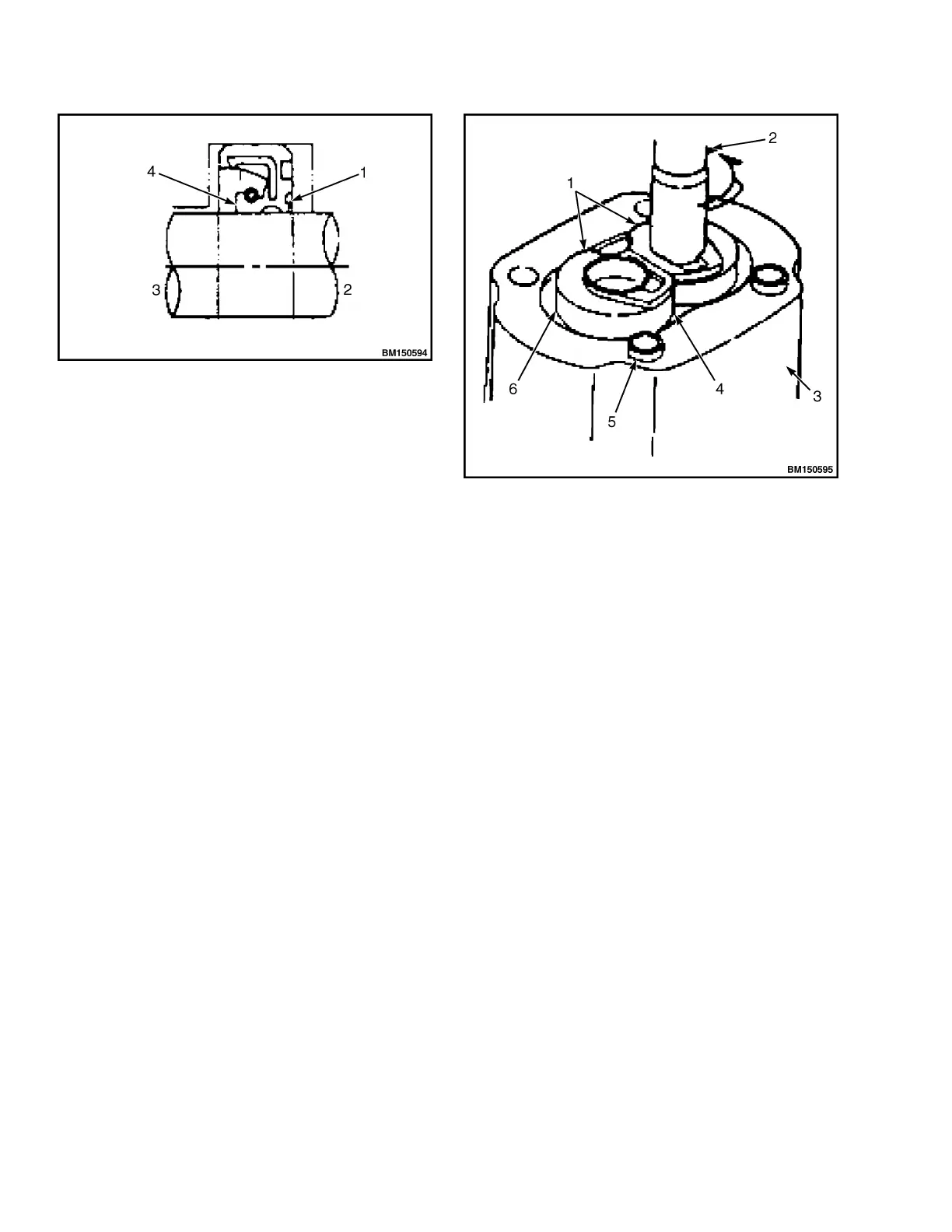

1. DUST-PROOF LIP

2. PUMP OUTER SIDE

3. PUMP INNER SIDE

4. SEAL RING NOZZLE

Figure 53. Oil Seal Inspection

Assemble, Main Oil Pump

NOTE: For the following procedures refer to Figure 55

or Figure 56.

1. Clean the disassembled parts.

2. Coat a thin layer of clean grease on the lips of oil

seals.

3. Place the pump body and the pump cover on a

flat stand. Coat the inner surface of the pump

body with clean hydraulic oil.

4. Place bearings into the pump body, and pay

attention to put them in correct positions. Do not

press it in forcibly. See Figure 54.

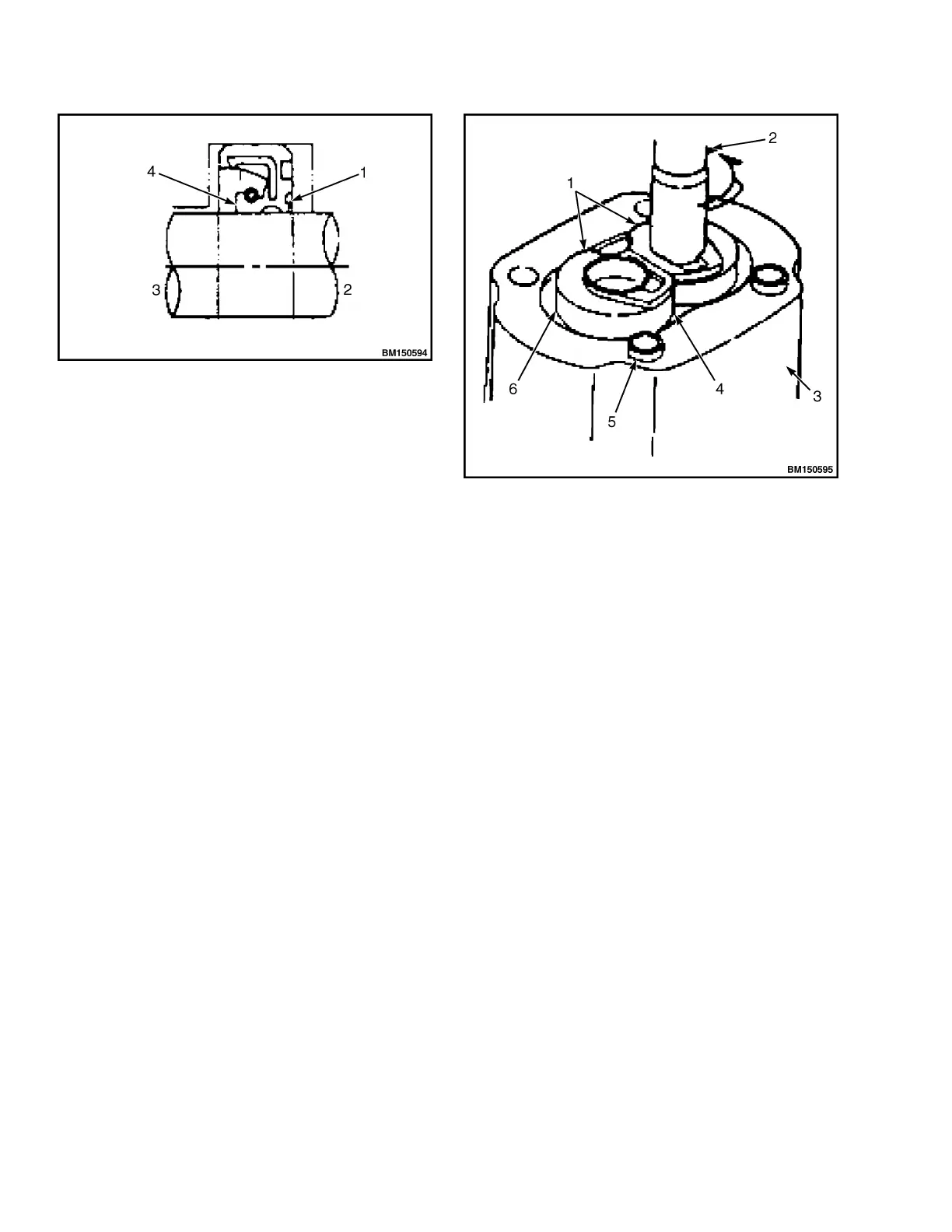

1. BEARING

2. DRIVING GEAR

3. INLET SIDE

4. CLEARANCE NOT ALLOWED

5. POSITIONING PIN (AT INLET SWITCH)

6. DRIVEN GEAR

Figure 54. Pump Body

5. Turn over the pump body. Put the driving and

driven gears (items 5-6) into the pump body, and

allow the engaged teeth to be at the same

position as prior to disassembly.

6. Mount the bearings (items 3-4) on one side of the

front end cover using the same method as in .

7. Mount the seal ring for pump body (item 8), the

seal ring for bearing (item 9), and seal rings

(items 10-11), and do not allow the seal rings to

overlap.

8. Assemble the front end cover (item 7), and wrap

the band around the end of driving gear to avoid

damage of oil ring lip. Remove the band after the

front end cover is mounted.

9. When pump body is turned over to mount end

cover, prevent seal rings from moving.

10. Mount seal rings (items 8-11), with the same

method as in Step 7.

11. Put on the end cover (item 11).

Hydraulic System 8000 YRM 2199

54

Loading...

Loading...