Legend for Figure 57.

1. HOSE CLAMP

2. PUMP SUCTION PIPE

3. PUMP SUCTION FITTING

4. 0-RING 35×3.5

5. GEAR PUMP

6. 0-RING 80×3.55

7. WASHER 10

8. WASHER 10

9. BOLT M10×35

10. 0-RING 22×2.4

11. PUMP OUTLET FITTING

12. VALVE H.P. HOSE

13. 0-RING 18×2.4

14. STEERING CYLINDER

CONNECTOR

15. STEERING CYLINDER H.P.

HOSE I

16. STEERING CYLINDER H.P.

HOSE II

17. ORBITAL PIPE

18. HOOP D25

19. ORBITAL PIPE CONNECTOR

20. ORBITAL CONNECTOR I

21. ORBITAL CONNECTOR II

22. ORBITAL

23. MULTI-CHANNEL VALVE-

HOSE II

24. CONNECTOR

25. VALVE INLET CONNECTOR

26. 0-RING 24×2.4

27. MULTI-CHANNEL VALVE

28. MULTI-CHANNEL VALVE-TILT

CYLINDER CONNECTOR

29. RETURN OIL HOSE

30. TILT CYLINDER PIPE I

31. TILT CYLINDER PIPE II

32. CLIP I

33. CLIP II

34. TILT CYLINDER HOSE

(FRONT)

35. TILT CYLINDER CONNECTOR

36. 0-RING 16×2.4

37. BOLT M6×25

38. WASHER 6

39. WASHER 6

40. NUT M6

41. BOLT M6×12

42. CLIP

43. BOLT M8×20

44. WASHER 8

45. NUT M8

46. CLAMP PLATE

47. CLAMP

48. CLIP

49. CABLE TIE

50. DIVERTER CONNECTOR

51. DIVERTER CONNECTOR

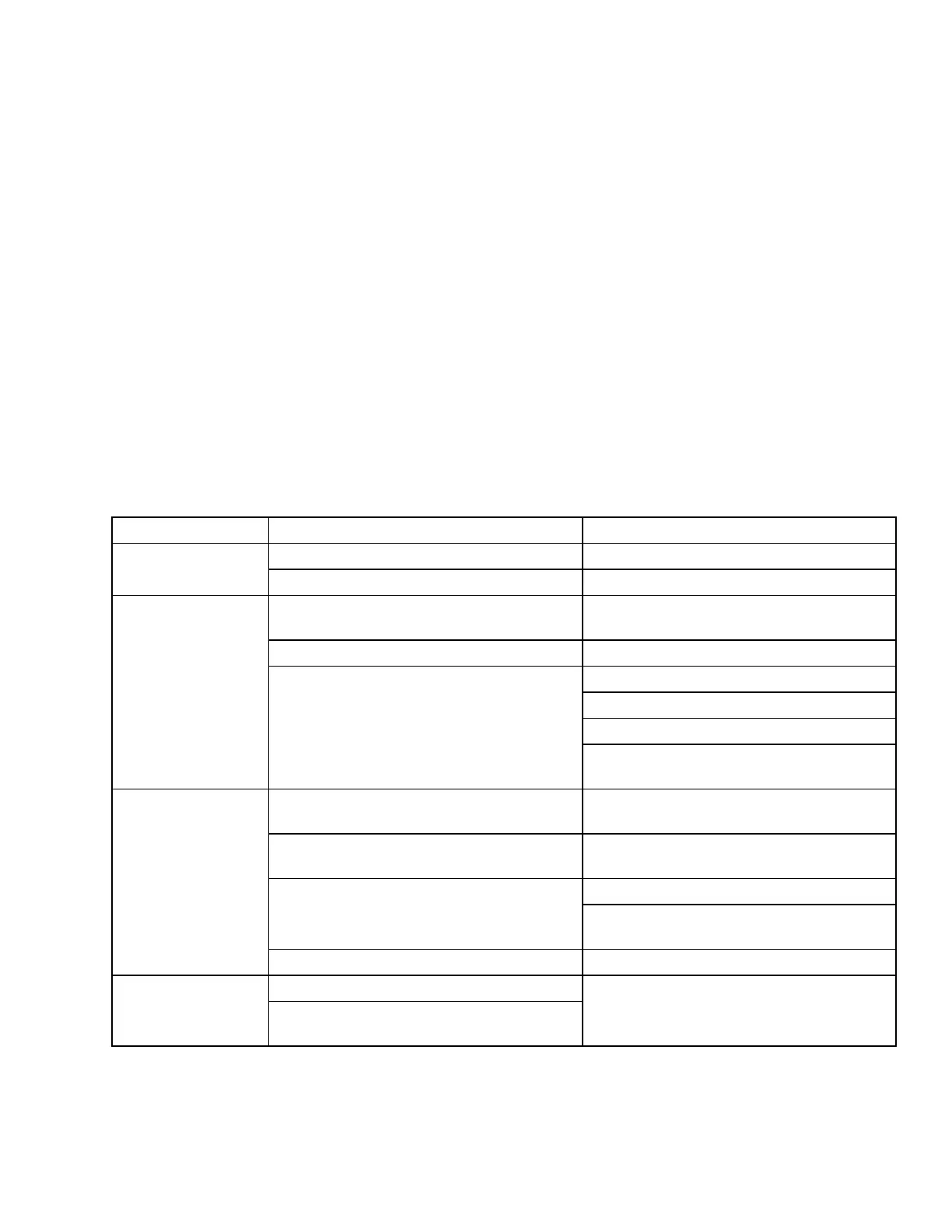

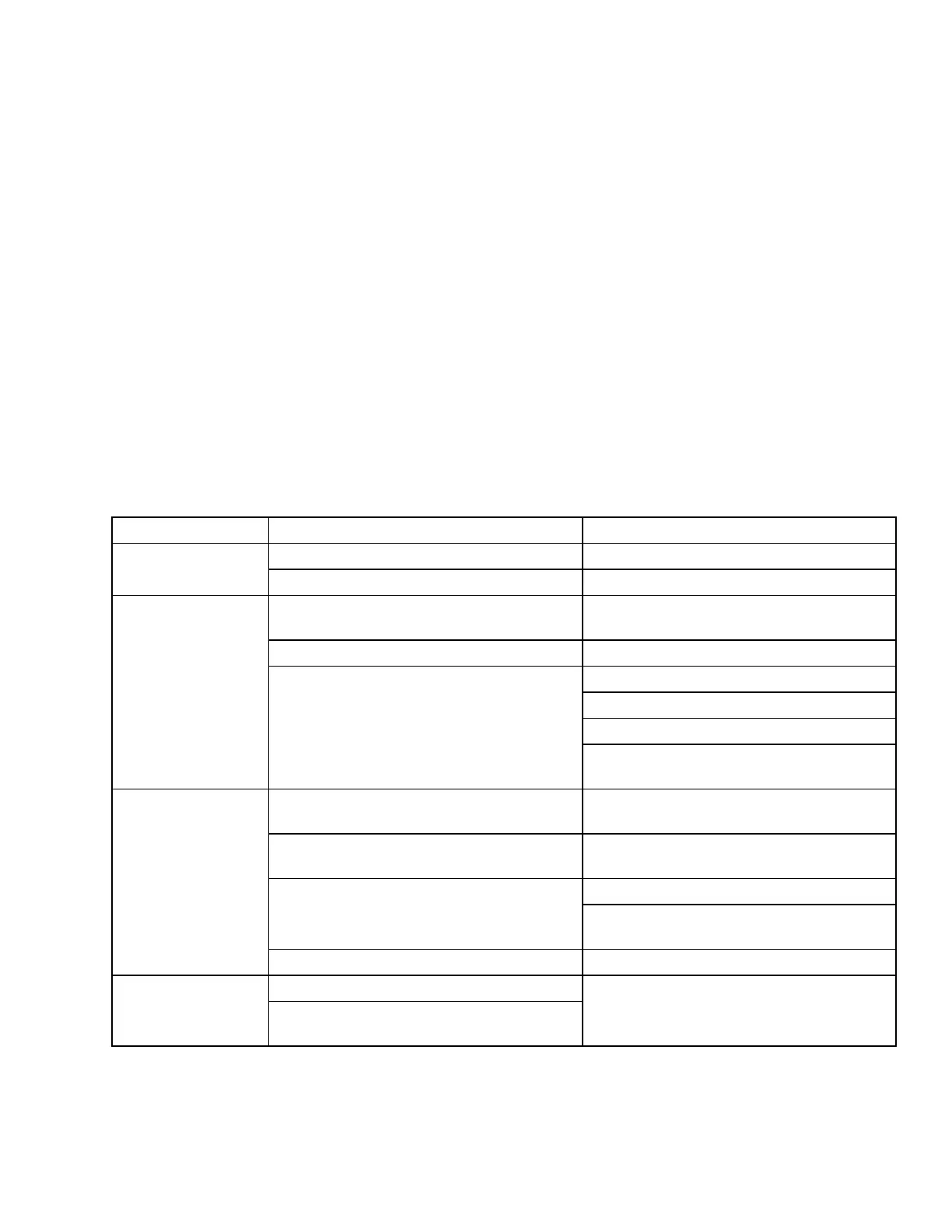

TROUBLESHOOT HYDRAULIC SYSTEM

Problem Cause Solution

Fluid Level Low

Fluid level in tank is at low end Fill fluid to the specified level

Fluid suction side pipeline or filter blocked Clean or replace fluid if dirty

Failure of Gear Pump

for Supercharge

Bearings are worn, and bearing seal rings

are at fault. Replace

Overflow valve misadjusted Raise pressure gauge

Air blended into pump

Tighten joint at suction pipe side

Add fluid into tank

Check pump seal

Run pump until there are no more air

bubbles in fuel tank

Noise of Gear Pump

Loud

Fluid suction hose twisted, or cavity blocked

by filter Clean filter and adjust hose

Air pulled inside due to loosening of fluid

suction side joint Tighten each joint

Excessive fluid viscosity

Use proper viscosity fluid

Do not operate until fluid temperature is

normal

Air bubble present in hydraulic fluid Check for cause of air bubble

Fluid Leak with Pump

Seal and seal ring of pump at fault

Replace

Sliding face worn (for internal leak to be

increased)

8000 YRM 2199 Hydraulic System

59

Loading...

Loading...