AFFZP0BB – ACE3 – User Manual Page – 61/139

7.2.5 HARDWARE SETTING

The HARDWARE SETTING parameters group includes the motor-control-related

parameters. Only those parameters the user can modify are here described.

4 For descriptions and teaching about missing parameters contact a Zapi technician.

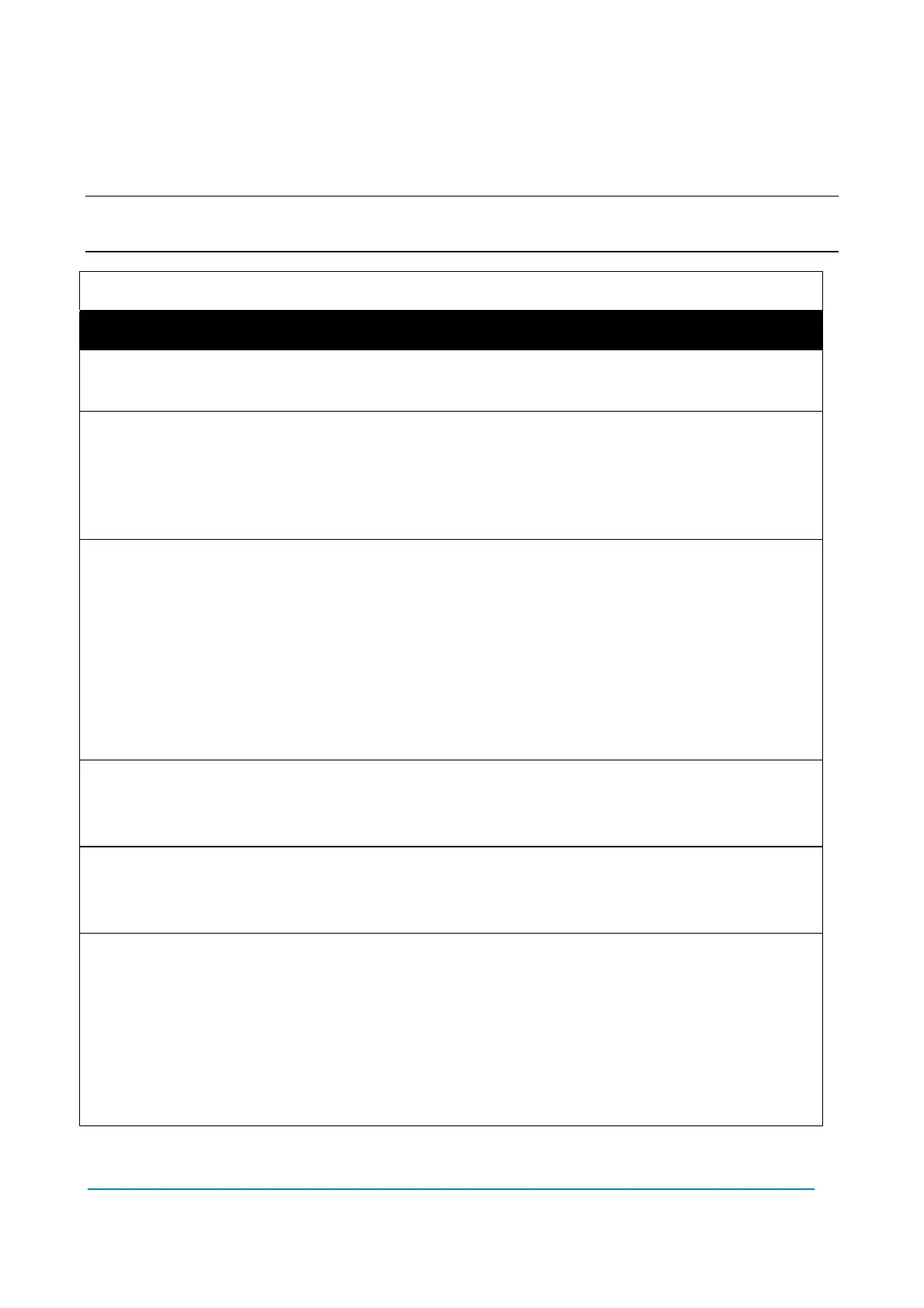

HARDWARE SETTING

Parameter Allowable range Description

TOP MAX SPEED

(T, TM, P, CO)

0 Hz ÷ 600 Hz

(by steps of 10 Hz)

This parameter defines the maximum motor speed.

CONF.POSITIVE LC

(A)

0 ÷ 2 This parameter defines the positive supply configuration

for the main-contactor coil.

0 = it is connected to PEB (A17)

1 = it is connected to KEY (A1)

2 = it is connected to SEAT input (A6)

FEEDBACK SENSOR

(A)

0 ÷ 4 This parameter defines the type of the adopted speed

sensor.

0 = incremental encoder

1 = sin/cos sensor

2 = incremental encoder + sin/cos sensor

3 = incremental encoder + sin/cos sensor + index

4 = PWM absolute sensor + incremental encoder +

index

5 = resolver

ROTATION CW ENC

(A)

OPTION#1, OPTION#2 This parameter defines the configuration of the encoder.

OPTION#1 = channel A anticipates channel B

OPTION#2 = channel B anticipates channel A

ROTATION CW MOT

(A)

OPTION#1, OPTION#2 This parameter defines the sequence of the motor phases.

OPTION#1 = U-V-W corresponds to forward direction.

OPTION#2 = V-U-W corresponds to forward direction.

ENCODER PULSES 1

(T, TM, P, CO)

32 ÷ 1024 This parameter defines the number of encoder pulses per

revolution. It must be set equal to ENCODER PULSES 2;

otherwise the controller raises an alarm.

The available options are:

32, 48, 64, 80, 64, 128, 256, 512, 1024

NOTE: with standard HW the capability to use

encoders with high number of pulses could be

limited depending on the speed. Ask to Zapi

technicians before changing this parameter.

Loading...

Loading...