187

ADJUSTMENT

ENGINE TRAVEL CLUTCH

ADJUSTMENT

The travel clutch is designed in such

manner that no adjustment is required

during the entire service life of clutch

plate lining. Full wear of the plate

becomes evident by clutch slipping. All

the three travel clutch levers must be in

one plane and must be in touch with the

clutch release sleeve. When replacing

the travel clutch plate, adjust the clutch

to the following value still at disas-

sembled tractor. Set the travel clutch

levers 25 mm from the recess in the

clutch cover by means of the nuts. The

difference in setting of the levers can be

maximum 0,15 mm. Depress the clutch

pedal approx. 5 times up to the stop after

assembly of the engine with the

transmission.

C772

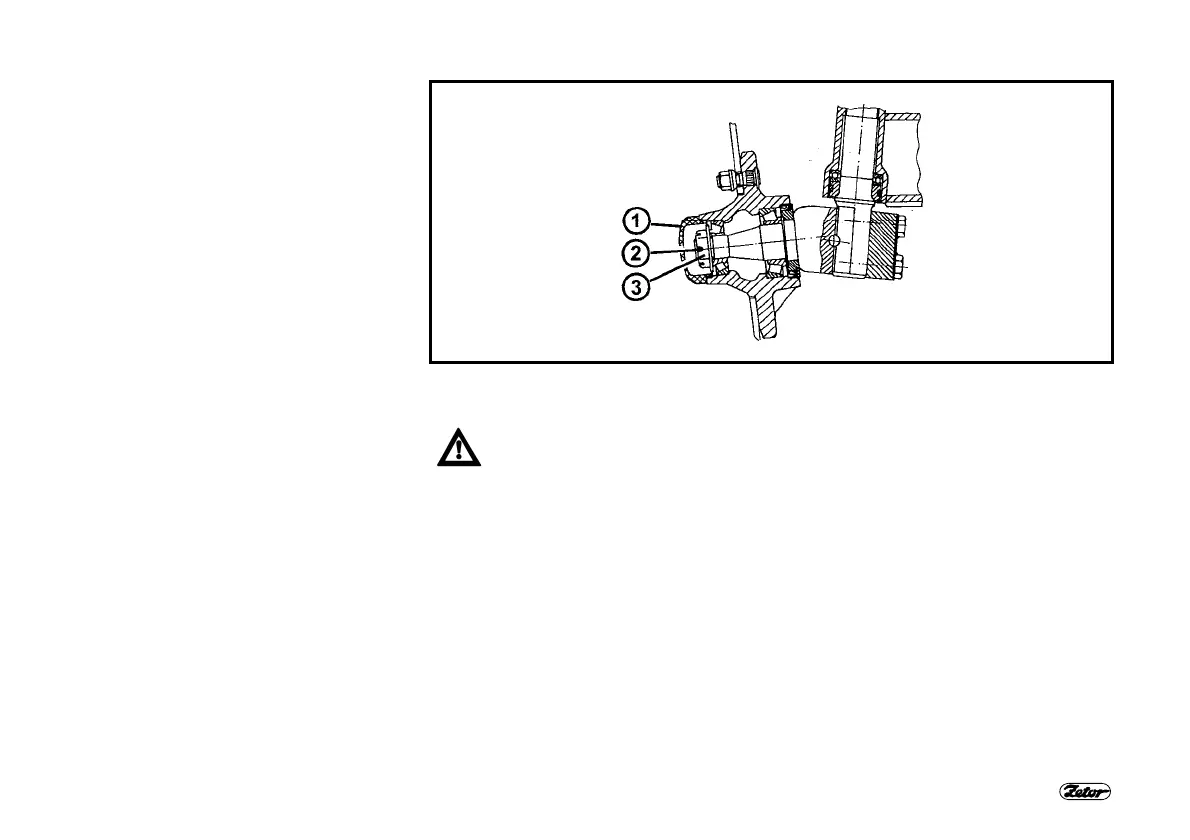

PLAY ADJUSTMENT OF FRONT WHEEL ROLLER BEARINGS AT TRACTOR

WITHOUT FRONT DRIVING AXLE

Secure the tractor against movement!

- Lift up and support the front axle.

- Screw off the bearing cover (1).

- Remove the cotter pin (2) from the slotted nut (3).

- Tighten the slotted nut (3) by torque 15 Nm.

- Loosen the nut by 180° and release the bearing by knocking with wooden mallet at

the wheel hub.

- Retighten the slotted nut (3) with torque wrench by torque 3-5 Nm. It must be

possible to turn the wheel freely without any evident play but without any evident

resistance. (Hub sealing resistance must be taken into consideration)

- Lock the slotted nut with a new cotter pin.

- Screw in the bearing cover.

Loading...

Loading...