35

Application Macro Motor Potentiometer

This macro provides a cost-effective interface for PLCs that vary the speed of

the drive using only digital signals.

The value of parameter 9902 is 4.

*Note!

• If both DI 3 and DI 4 are active or inactive, reference is kept stable.

• Reference is stored during stop or power down condition.

• Analogue reference is not followed when motor potentiometer is

selected.

Motor potentiometer parameter values:

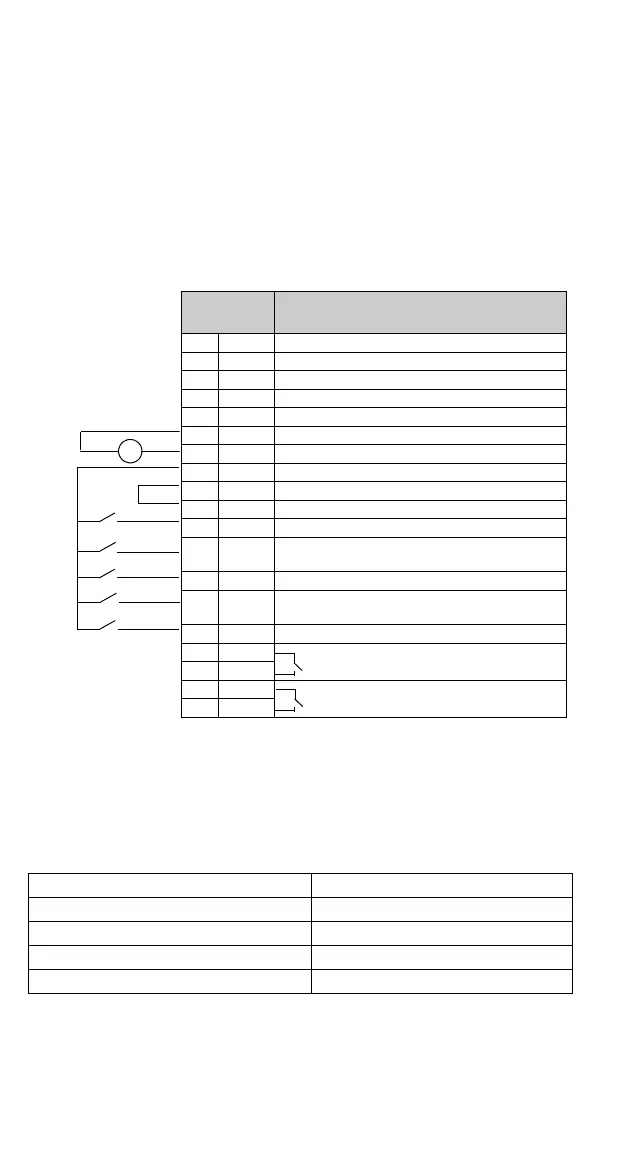

Input signals Output signals

• Start, stop and direction (DI1,2) • An. output AO: Frequency

• Reference up (DI3) • Relay output 1: Fault

• Reference down (DI4) • Relay output 2: Running

• Preset speed selection (DI5)

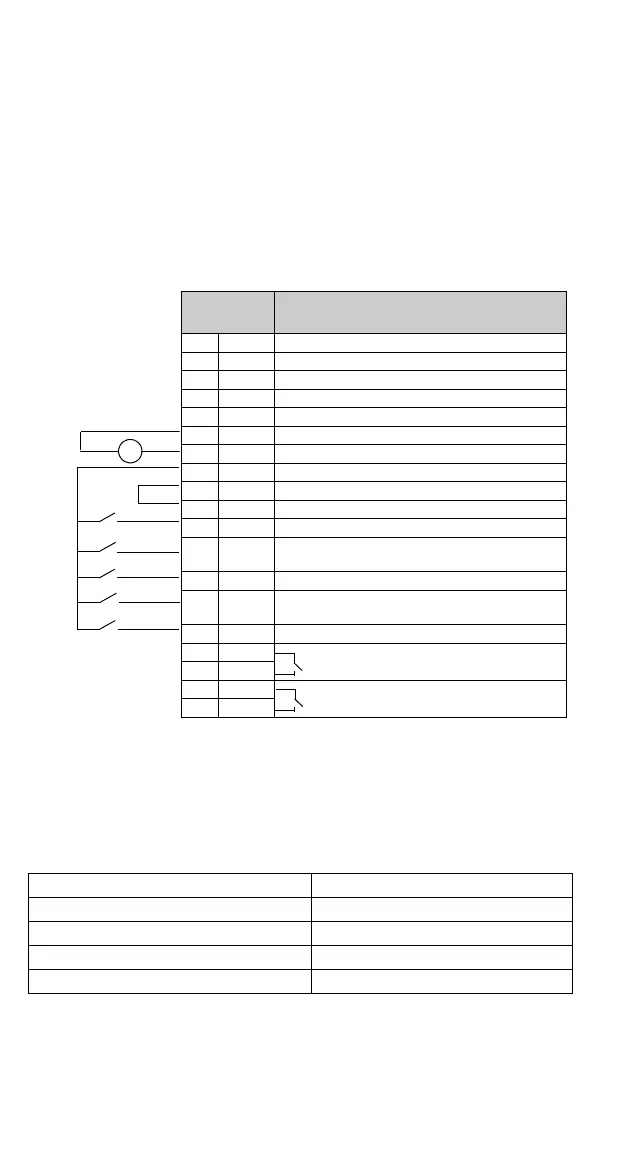

1001

EXT 1 COMMANDS 2 (DI1,2) 1106 EXT REF2 SELECT 0 (KEYPAD)

1002

EXT 2 COMMANDS 0 (NOT SEL) 1201 CONST SPEED SEL 5 (DI5)

1003

DIRECTION 3 (REQUEST) 1601 RUN ENABLE 0 (NOT SEL)

1102

EXT1/EXT2 SEL 6 (EXT1) 2105 PREMAGN SEL 0 (NOT SEL)

1103

EXT REF1 SELECT 6 (DI3U,4D) 2201 ACC/DEC 1/2 SEL 0 (NOT SEL)

Control

Terminal s

Function

1SCR

2 AI 1 Not used

3AGND

4 10 V Reference voltage 10 VDC

5 AI 2 Not used

6AGND

7 AO Output frequency 0...20 mA <=> 0...50 Hz

8AGND

9 +12 V +12 VDC

10 DCOM

11 DI 1 Start/Stop: Activate to start ACS140

12 DI 2 Forward/Reverse: Activate to reverse rotation

direction

13 DI 3 Reference up: Activate to increase reference*

14 DI 4 Reference down: Activate to decrease

reference*

15 DI 5 Constant speed 1

16 RO 1A Relay output 1

Fault: open

17 RO 1B

18 RO 2A Relay output 2

Running: closed

19 RO 2B

mA

www.barghmaher.org

Loading...

Loading...